Waste tinned wire excess material recovery device

A recycling device and tin-plating technology, applied in the direction of electronic waste recycling, recycling technology, circuits, etc., to achieve the effects of improving purity, improving economic benefits, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

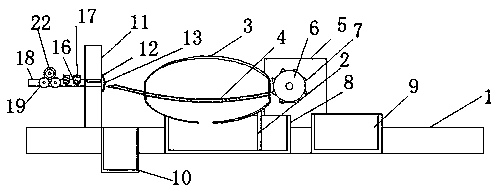

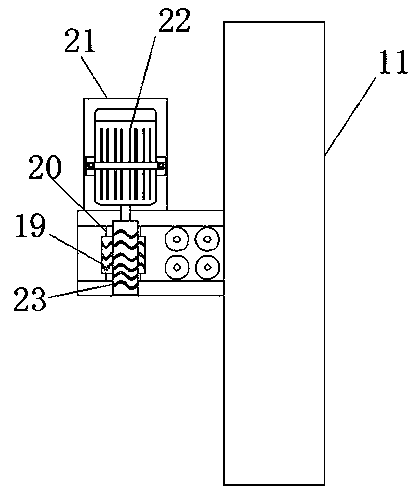

[0026] refer to Figure 1-4 , a waste and old tinned electric wire residue recovery device, comprising a base 1, the top of the base 1 is provided with a rectangular groove, the base 1 is provided with a tin oxide recovery tank 8 at the rectangular groove, and the tin oxide recovery tank 8 is a The bottom end of the side is welded with a pole 2, the tin oxide recovery tank 8 and the top of the pole 2 are welded with an electromagnetic heating chamber 3, the electromagnetic heating chamber 3 is connected to the circuit of the device, and both ends of the electromagnetic heating chamber 3 are equipped with Circular through holes, the inside of the electromagnetic heating chamber 3 is welded with curved grooves 4 at the two circular through holes, the bottom of the electromagnetic heating chamber 3 is provided with a through hole, when tin is converted into tin oxide, the tinned copper The wire is sent into the electromagnetic heating chamber 3 for heating, and the temperature is...

Embodiment 2

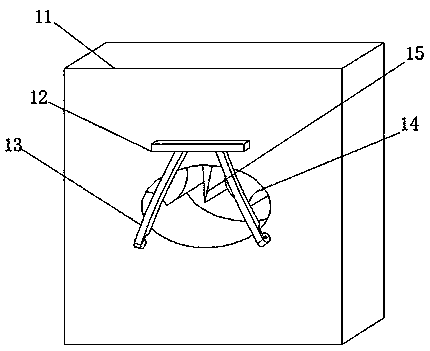

[0035] refer to Figure 5 , a recycling device for waste and old tinned electric wires. Compared with Embodiment 1, in this embodiment, in order to improve the stability of the electric wire during peeling, the second fixing plate 11 is positioned on both sides above the circular through hole. Open a rectangular groove, the second fixed plate 11 is welded with a U-shaped bar 25 at the rectangular groove, and the outside of the U-shaped bar 25 is connected with an elastic wheel 24 through the rotation of the shaft. Tightly apply pressure to the wires at all times to prevent the wires from being twisted when they are stripped and improve the stability of the device.

[0036] When in use, when tin is converted into tin oxide, the tinned copper wire is sent into the electromagnetic heating chamber 3 for heating, and the temperature is kept at 140°C. On the discarded tinned copper wire, the inside of the tin layer has not been completely oxidized Tin and stannous oxide react with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com