Nickel oxide/porous carbon material capable of being used for lithium ion battery negative electrode as well as preparation method and application of nickel oxide/porous carbon material

A lithium-ion battery and porous carbon technology, which is applied to battery electrodes, secondary batteries, electrochemical generators, etc., can solve problems such as lifting, metal oxide shedding, and uneven distribution of nickel oxide, so as to achieve rich raw materials and reliable The effect of strong controllability and excellent lithium battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

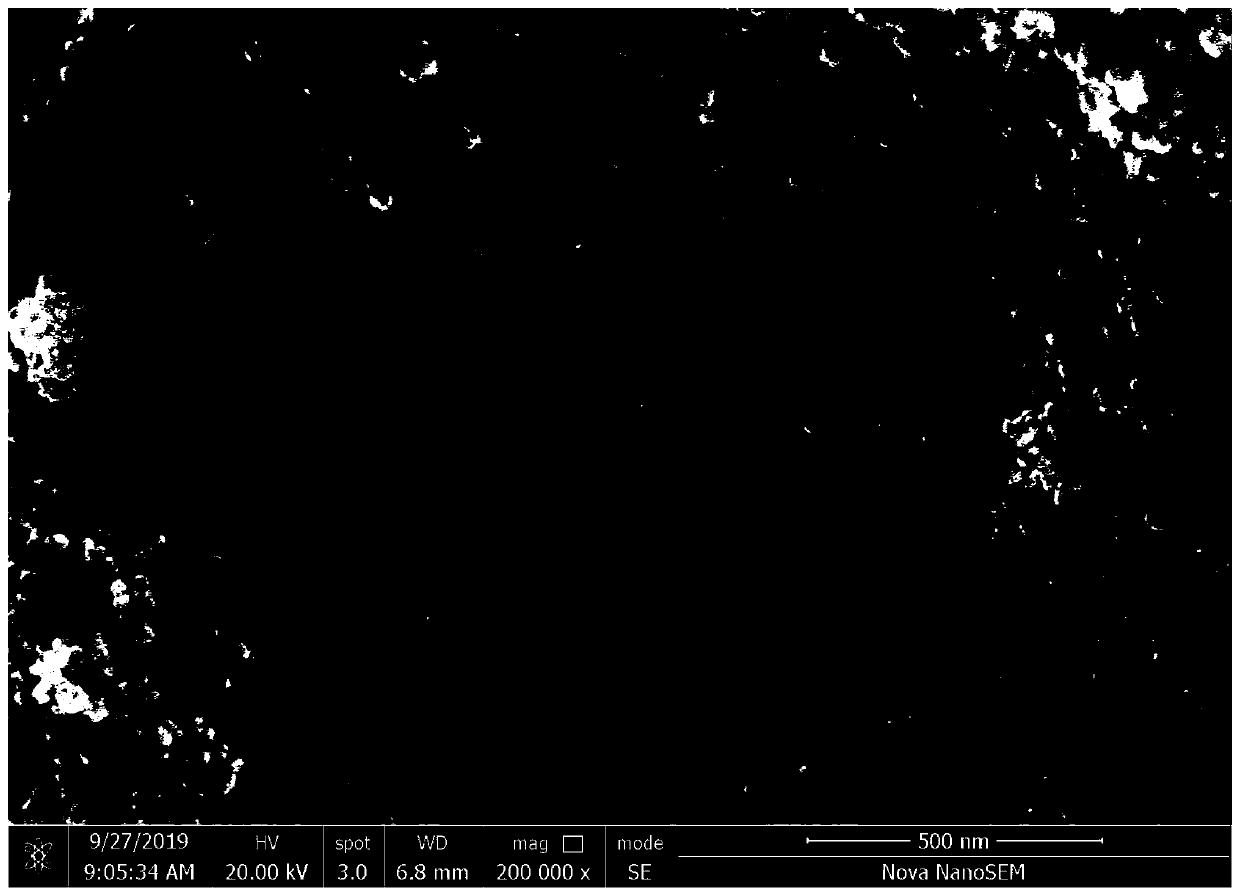

Image

Examples

Embodiment 1

[0020] A mixture of 2 mmol of nickel nitrate, 0.5 mmol of terephthalic acid, and 1.5 mmol of trimesic acid was dissolved in 40 mL of DMF, labeled as solution A. Then the solution was put into a hydrothermal kettle and reacted at 120 °C for 8 h to obtain Ni-MOFs. The product was rinsed three times with ethanol and dried at 50 °C for 12 h. Put the dried Ni-MOFs in a porcelain ark into a tube furnace, raise the temperature to 700°C at 2°C / min in an argon atmosphere, and react for 1h to obtain a nickel / porous carbon material, then place it in an air atmosphere Rise to 250°C at 2°C / min, and react for 1 hour to obtain nickel oxide / porous carbon material.

Embodiment 2

[0022] Dissolve a mixture of 3 mmol of nickel nitrate, 0.1 mmol of 1, 2, 2, and 1.9 mmol of trimesic acid in 40 mL of DMF, labeled as solution A. Then the solution was put into a hydrothermal kettle and reacted at 130 °C for 9 h to obtain Ni-MOFs. The product was rinsed three times with ethanol and dried at 50 °C for 12 h. The dried Ni-MOFs were placed in a porcelain ark and placed in a tube furnace, heated to 800°C at 2°C / min in an argon atmosphere, and reacted for 2h to obtain a nickel / porous carbon material, which was then placed in an air atmosphere Rise to 300°C at 2°C / min and react for 2h to obtain nickel oxide / porous carbon material.

Embodiment 3

[0024] A mixture of 3 mmol of nickel nitrate, 0.2 mmol of terephthalic acid and 1.8 mmol of trimesic acid was dissolved in 40 ml of DMF, labeled as solution A. Then the solution was put into a hydrothermal kettle and reacted at 140 °C for 10 h to obtain Ni-MOFs. The product was rinsed three times with ethanol and dried at 50 °C for 12 h. Put the dried Ni-MOFs in a porcelain ark into a tube furnace, raise the temperature to 900°C at 2°C / min in an argon atmosphere, and react for 3h to obtain a nickel / porous carbon material. Raise to 300°C at 2°C / min, react for 1h, and obtain nickel oxide / porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com