High-voltage birotor magnetic circuit structure

A dual-rotor, magnetic circuit technology, applied in the magnetic circuit shape/style/structure, magnetic circuit, magnetic circuit rotating parts, etc., can solve the problem that cannot meet the requirements of slender motors, increase rotor structural components, increase rotor failure rate, etc. To achieve the effect of saving permanent magnet materials, increasing output power, and improving magnetic flux utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

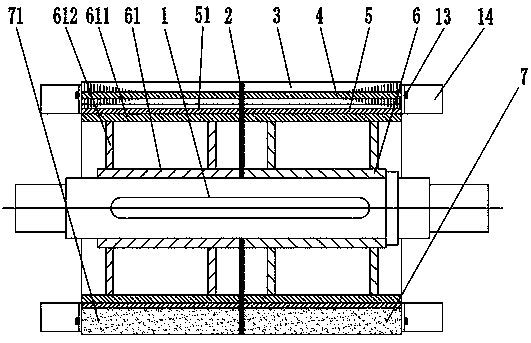

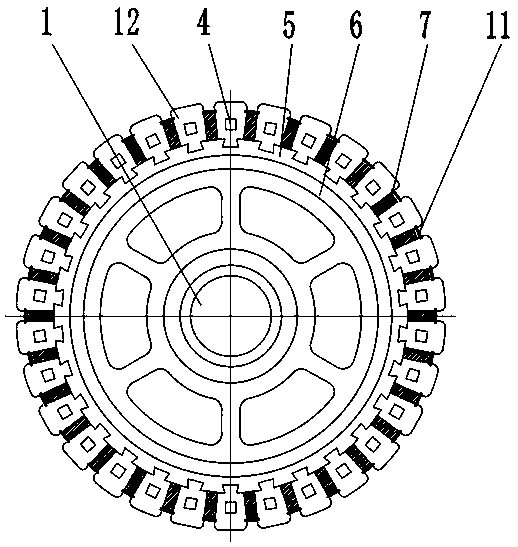

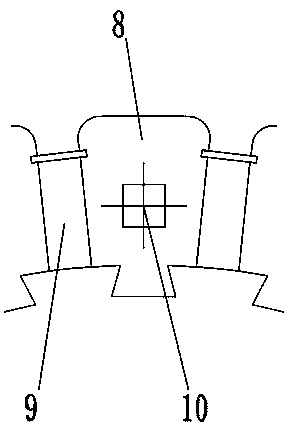

[0034]A high-voltage double-rotor magnetic circuit structure, used for 1000KW, 10KV large-scale high-voltage variable-frequency low-speed high-torque permanent magnet synchronous motors, the length-to-diameter ratio of the rotor is 15, and the outer cylindrical surface of the rotor shaft 1 is provided with right-hand rotation from right to left The sub-support 6, the magnetic isolation spacer 2 and the left rotor support 61, the magnetic isolation spacer 2 is the middle ring in claim 1, the right rotor support 6 and the left rotor support 61 have the same structure, and the left rotor support 61 is the For example, the left rotor bracket outer cylinder 611 is fixed on the outer cylindrical surface sleeved on the rotor shaft 1 through the left rotor bracket web 612, and is restricted from rotating relative to the rotor shaft 1 on the rotor shaft 1 by a flat key. The rotor bracket 6, the magnetic isolation spacer plate 2 and the left rotor bracket 61 are close together, and each ...

Embodiment 2

[0036] A high-voltage dual-rotor magnetic circuit structure, used for 1300KW, 10KV large-scale high-voltage variable-frequency low-speed high-torque permanent magnet synchronous motors, the length-to-diameter ratio of the rotor is 18, and the outer cylindrical surface of the rotor shaft 1 is provided with right-hand rotation from right to left The sub-support 6, the magnetic isolation spacer 2 and the left rotor support 61, the magnetic isolation spacer 2 is the middle ring in claim 1, the right rotor support 6 and the left rotor support 61 have the same structure, and the left rotor support 61 is the For example, the left rotor bracket outer cylinder 611 is fixed on the outer cylindrical surface sleeved on the rotor shaft 1 through the left rotor bracket web 612, and is restricted from rotating relative to the rotor shaft 1 on the rotor shaft 1 by a flat key. The rotor bracket 6, the magnetic isolation spacer plate 2 and the left rotor bracket 61 are close together, and each r...

Embodiment 3

[0038] A high-voltage dual-rotor magnetic circuit structure, used for 900KW, 10KV large-scale high-voltage variable-frequency low-speed high-torque permanent magnet synchronous motors, the length-to-diameter ratio of the rotor is 13, and the outer cylindrical surface of the rotor shaft 1 is provided with right-hand rotation from right to left The sub-support 6, the magnetic isolation spacer 2 and the left rotor support 61, the magnetic isolation spacer 2 is the middle ring in claim 1, the right rotor support 6 and the left rotor support 61 have the same structure, and the left rotor support 61 is the For example, the left rotor bracket outer cylinder 611 is fixed on the outer cylindrical surface sleeved on the rotor shaft 1 through the left rotor bracket web 612, and is restricted from rotating relative to the rotor shaft 1 on the rotor shaft 1 by a flat key. The rotor bracket 6, the magnetic isolation spacer plate 2 and the left rotor bracket 61 are close together, and each ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com