Pet food forming machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

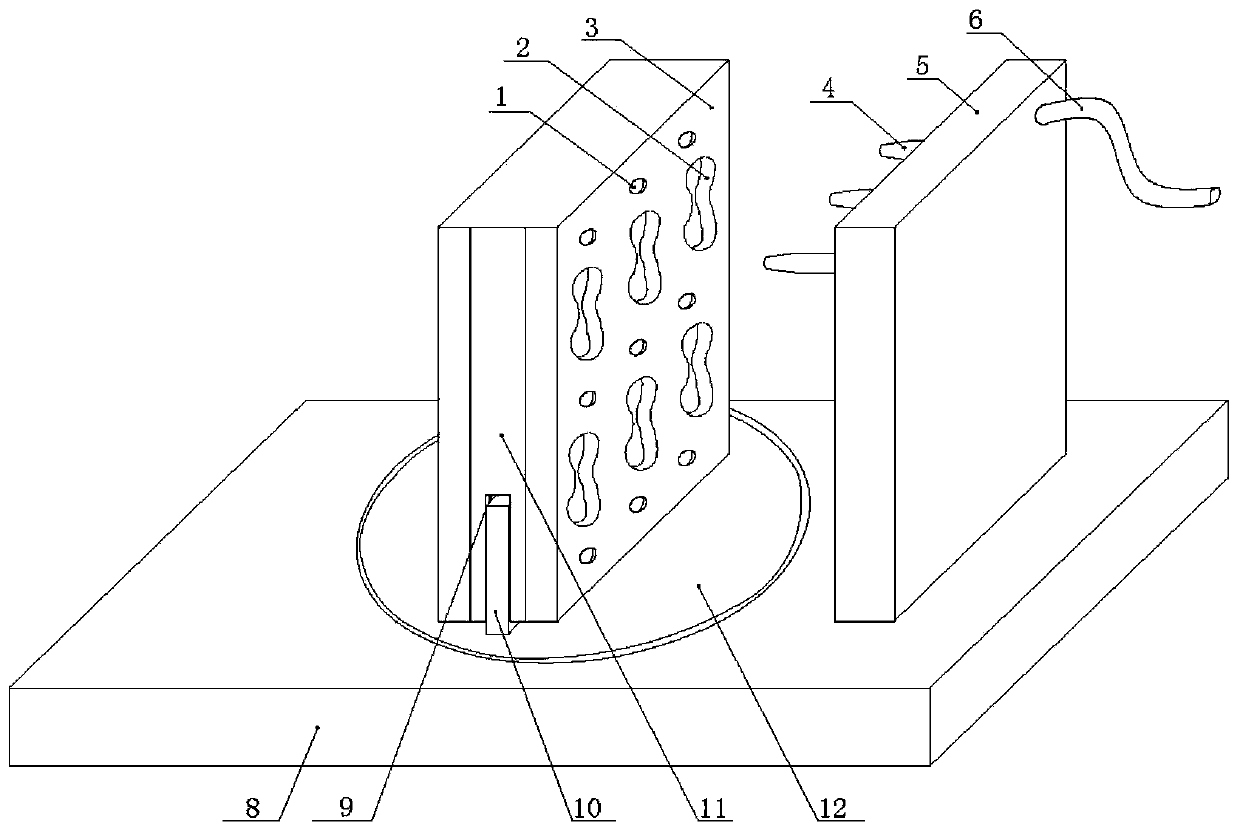

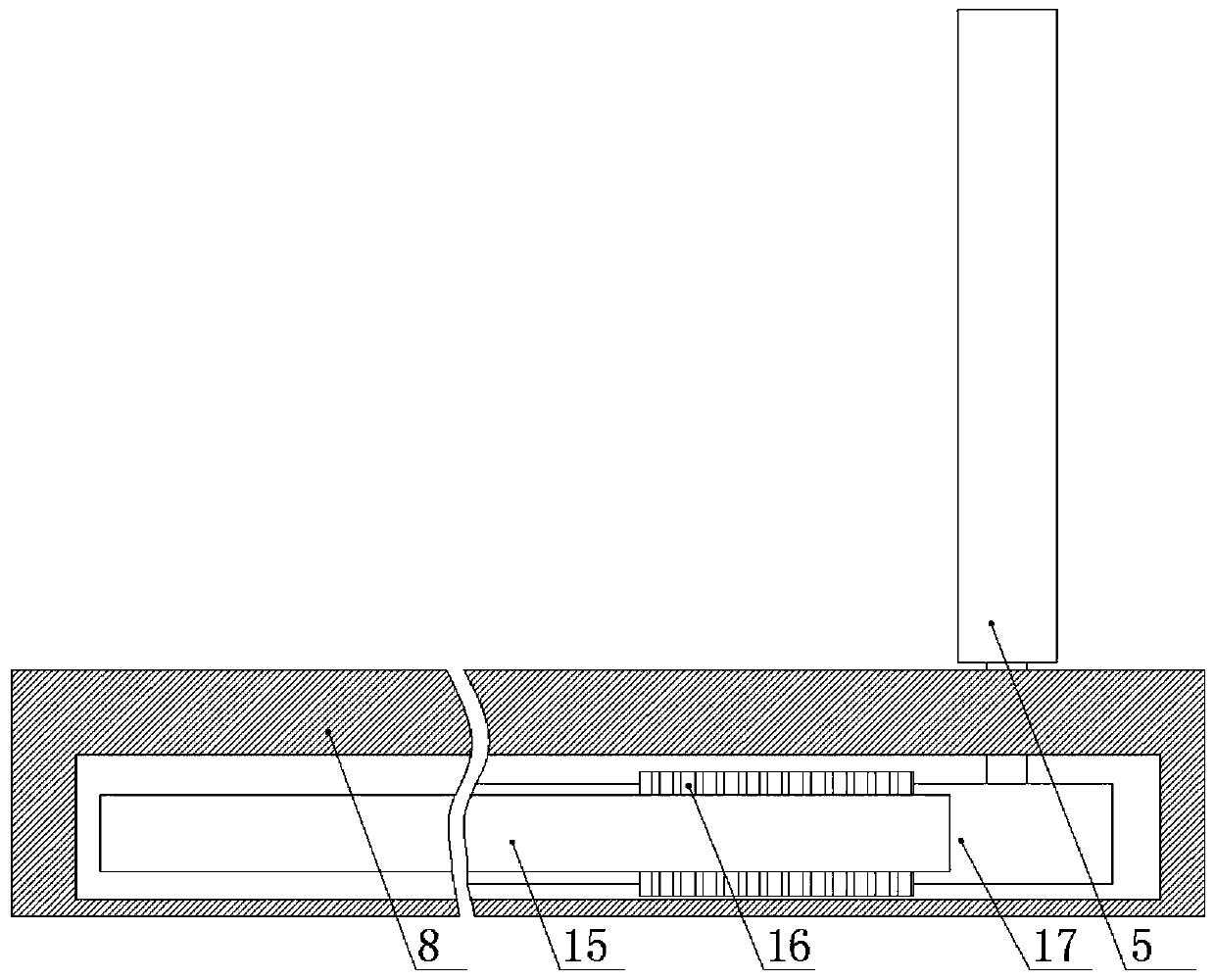

[0026] like figure 1 As shown, the pet food molding machine includes a bottom plate 8 fixed at the outlet of the injection molding machine, that is, the injection molding machine is located on the left side of the bottom plate 8, and the injection molding machine in this embodiment adopts an existing horizontal injection molding machine. A turntable 12 is rotatably installed on the bottom plate 8 , and the top of the turntable 12 is flush with the upper surface of the bottom plate 8 . Turntable 12 is vertically welded with inserting plate 10 for fixing fixed mold 3. In this embodiment, fixed mold 3 is provided with several cavities 2 on both sides. The number of cavities 2 on one side of fixed mold 3 in this embodiment for six. A cooling plate 11 is vertically arranged inside the fixed mold 3 , and the cooling plate 11 is integrally formed with the fixed mold 3 , and the bottom of the cooling plate 11 is provided with a slot 9 for inserting the above-mentioned inserting plate...

Embodiment 2

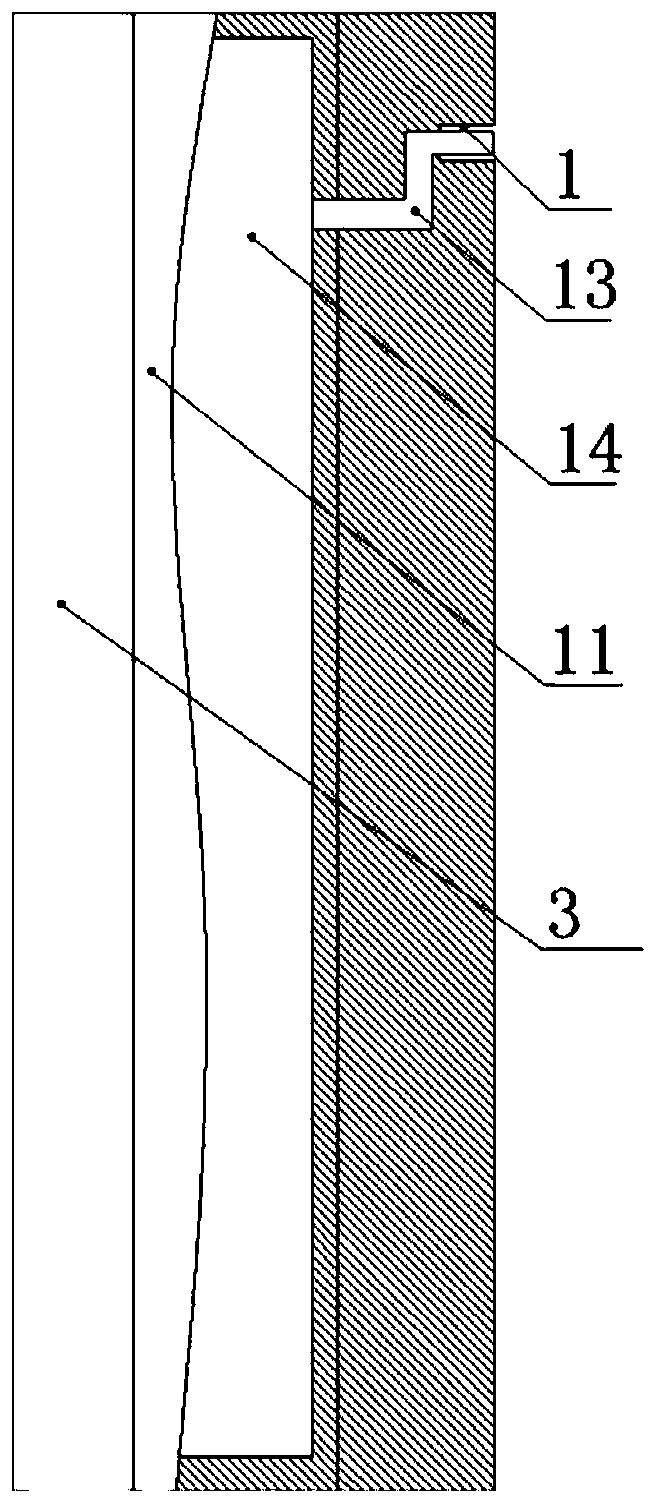

[0038] The difference between this embodiment and the first embodiment is that the cooling chamber 14 includes a left chamber and a right chamber separated from each other, and the water inlet pipes 13 on the left and right sides of the fixed mold 3 communicate with the left chamber and the right chamber respectively. If only one cooling chamber 14 is used, the entire cooling chamber 14 needs to be filled with cooling water to achieve a uniform cooling effect, but this makes the cooling chamber 14 unable to store the cooling water injected from the other side of the fixed mold 3 . In this embodiment, the left chamber and the right chamber separated from each other are set to respectively store the cooling water injected from both sides of the fixed mold 3, so as to solve the above problems.

Embodiment 3

[0040] The difference between this embodiment and the second embodiment is that sponges are placed in both the left chamber and the right chamber, and the volume of the sponge after absorbing water is the same as that of the left chamber and the right chamber. With such arrangement, the cooling water can be evenly distributed in the left chamber or the right chamber by using the sponge, and there is no need to fill the left chamber and the right chamber with cooling water, which saves the consumption of cooling water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com