Operation optimization method for assisting wastewater commissioning of wet desulphurization system

A technology for wet desulfurization and operation optimization, applied in chemical instruments and methods, separation methods, control/manipulation systems, etc., can solve problems such as desulfurization efficiency decline, poor wastewater treatment effect, unplanned treatment capacity, etc., to achieve operational convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

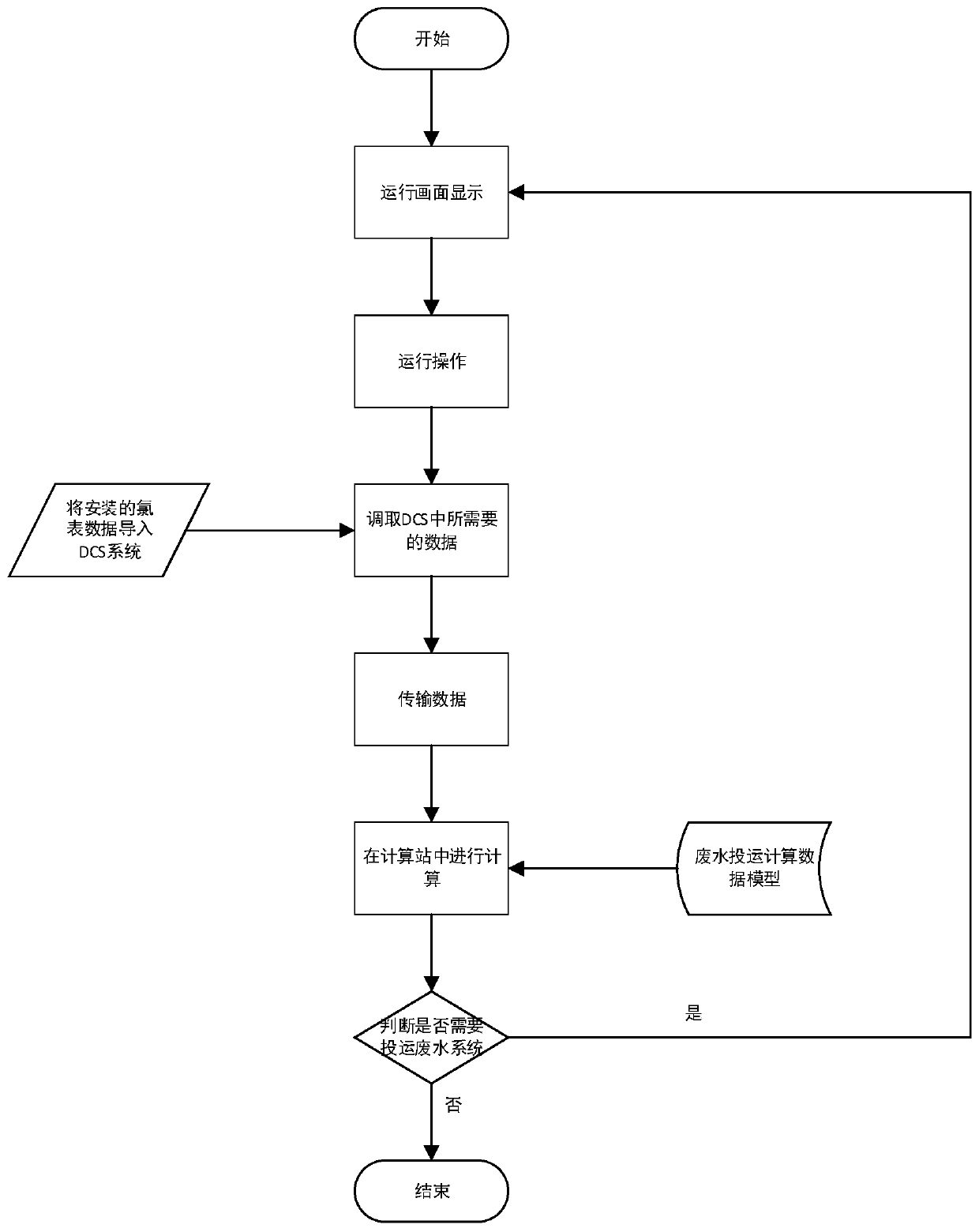

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] refer to figure 1 According to the present invention, the operation optimization method for auxiliary wastewater commissioning of wet desulfurization system comprises the following steps:

[0024] 1) Construct the calculation model of the wastewater treatment and discharge online operation control system;

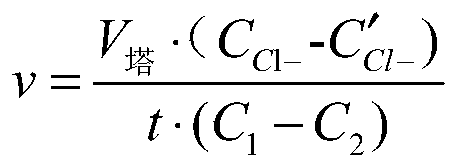

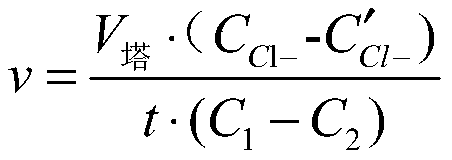

[0025] The expression of the calculation model of the wastewater treatment and discharge online operation control system is:

[0026]

[0027] Among them, v is the wastewater treatment flow rate of the desulfurization tower, V 塔 is the volume of the slurry in the desulfurization tower, C' Cl- is the target concentration of chloride ions in the slurry in the desulfurization tower, and t is the planned operation time of the waste water system to input the waste water into the desulfurization tower.

[0028] 2) Obtain the chloride ion concentration C of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com