Aluminum or copper laser 3D printing blade face steel bar adhesive tape composite powder scraper

A 3D printing and scraper technology, applied in the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve problems such as residual stress increase, residual stress, scraper hitting parts, etc., to improve connection stability, Avoid bias moment, avoid further deterioration of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

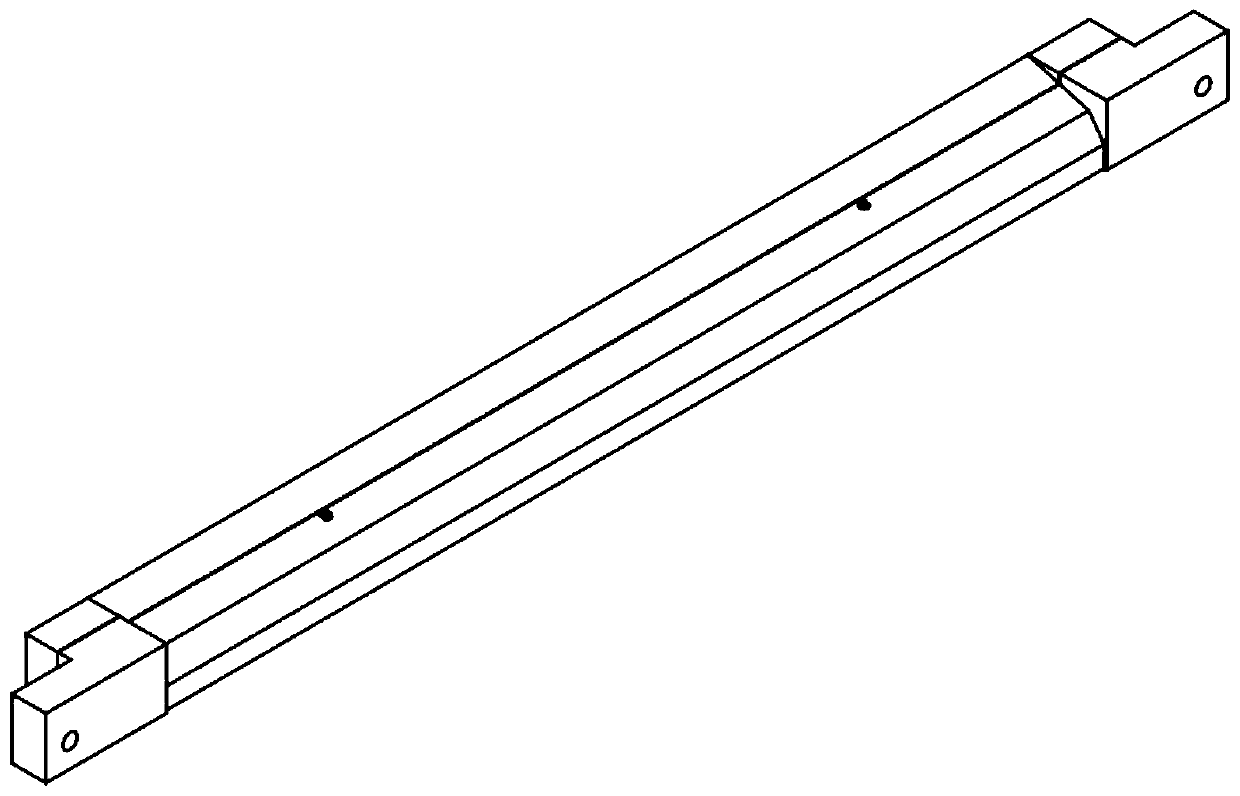

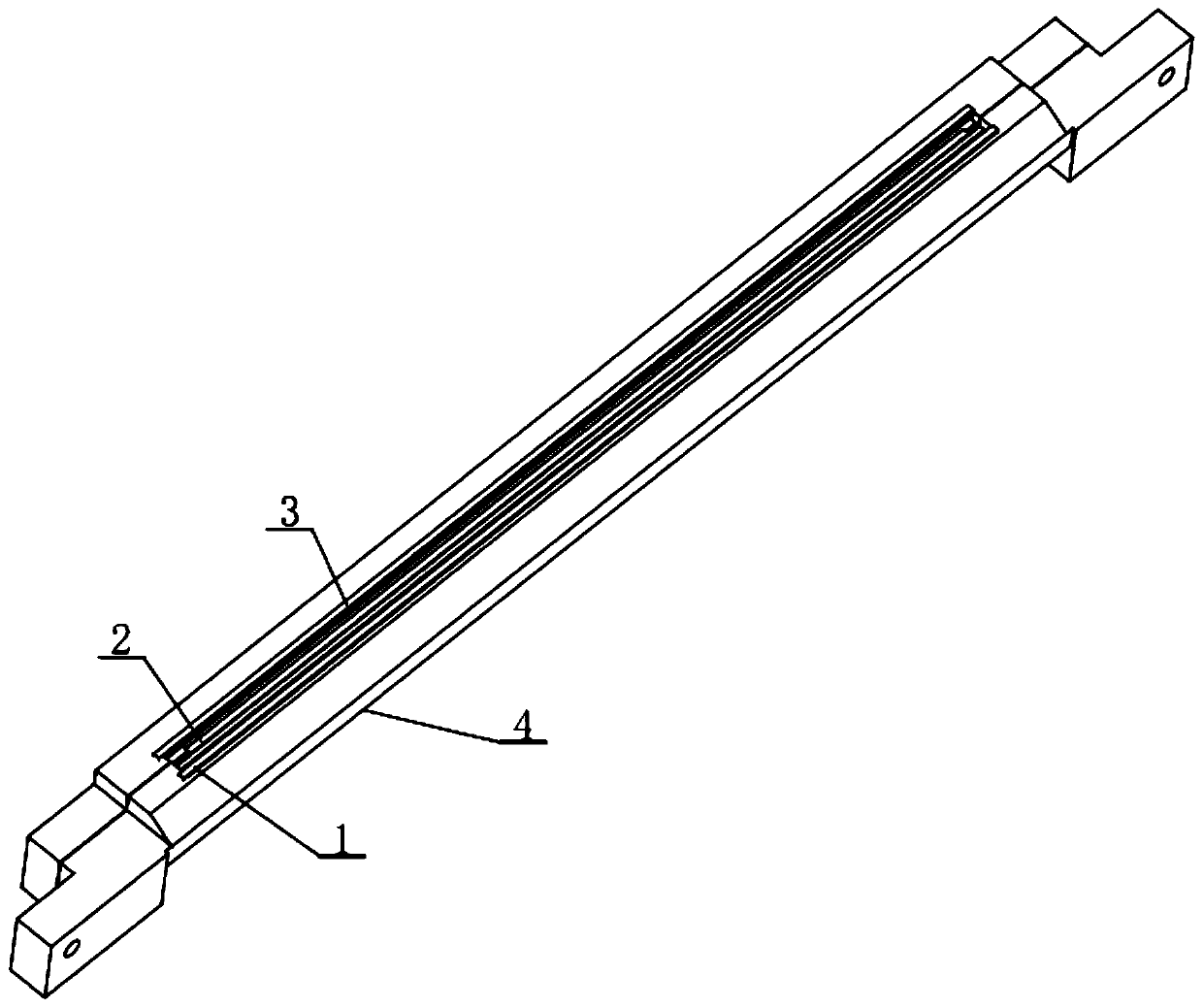

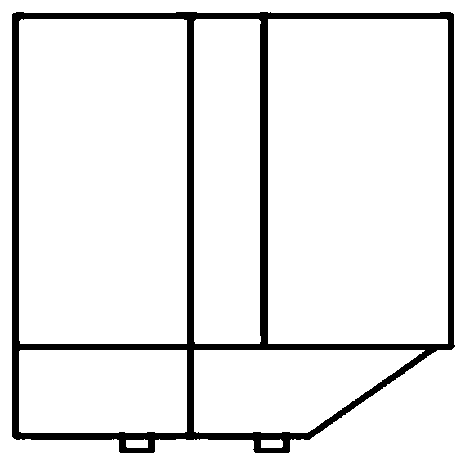

[0060] Embodiment 1: as Figure 1-Figure 8 As shown, an aluminum or copper laser 3D printing edge-surface steel strip rubber compound scraper includes a front K-shaped rubber strip scraper 1, a blade-surface steel strip scraper 2, a rear K-shaped rubber strip scraper 3, and a front K-shaped rubber strip scraper. The strip scraper 1, the steel strip scraper 2 and the rear K-shaped rubber strip scraper 3 are fixedly connected on the knife holder 4, and the steel strip scraper 2 is located in the middle of the front K-shaped rubber strip scraper 1 and the rear K-shaped rubber strip scraper 3.

[0061] Preferably, the blades of the above-mentioned front K-shaped rubber strip scraper 1 and the rear K-shaped rubber strip scraper 3 are in the same plane, and the blade surface steel strip scraper 2 is lower than the front K-shaped rubber strip scraper 1 or the rear K-shaped rubber strip scraper. Blade 0.03-0.05mm of the blade surface of 3.

[0062] Preferably, there is a gap between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com