Processing device for extracting green bamboo stem fibers and processing method thereof

A technology of processing equipment and processing methods, which is applied in the direction of wood processing equipment, manufacturing tools, cleaning devices, etc., can solve the problems that are not conducive to the economic benefits of green bamboo stem fibers, low thermal movement of green bamboo stems, and low penetration force. , to achieve the effect of improving operating speed and efficiency, quiet working environment, and less operational failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

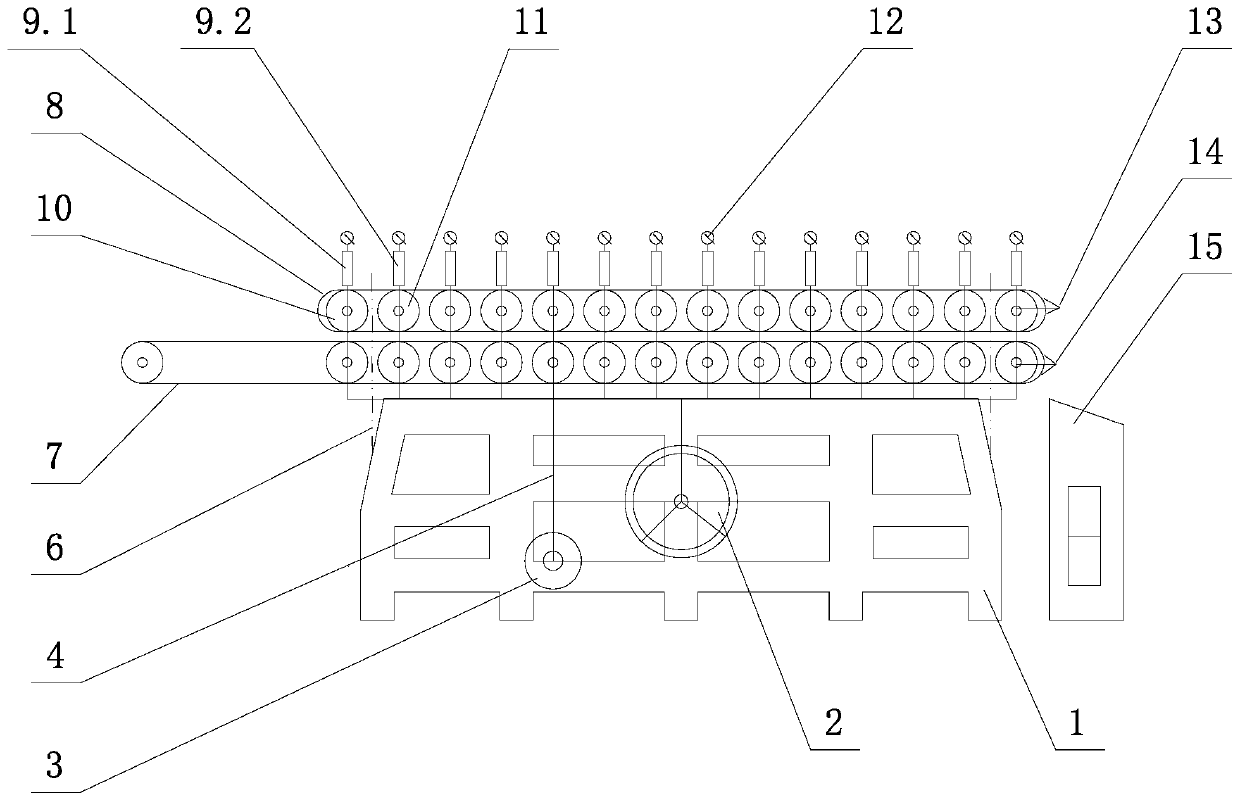

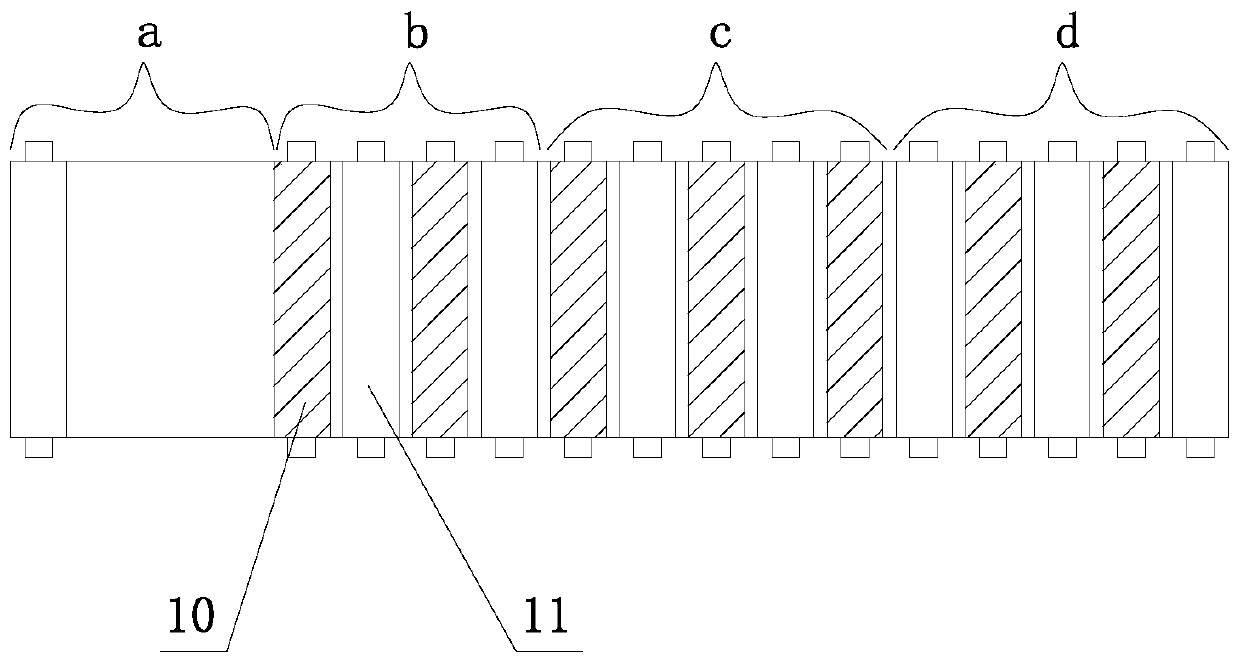

[0033] see Figure 1-Figure 2 , the processing equipment used to extract green bamboo stalk fibers, including the conveyor belt arranged on the frame, the conveyor belt includes the upper conveyor belt 8 located above and the lower conveyor belt 7 located below, after fragments and cooking The green bamboo stalk is positioned between the upper conveyor belt 8 and the lower conveyor belt 7, and flexible rollers 10 and rigid rollers 11 are respectively spaced apart in the upper conveyor belt 8 and the lower conveyor belt 7, wherein the flexible rollers positioned in the upper conveyor belt 8 The rollers 10 or rigid rollers 11 are set up and down corresponding to the rigid rollers 11 located in the lower conveyor belt 7 .

[0034] The frame is also provided with a variable frequency drive mechanism for driving the upper conveyor belt 8 and the lower conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com