Pull-type solid-liquid separation system for shield tunneling machine and separation method

A solid-liquid separation and trailer-type technology, which is applied in chemical instruments and methods, centrifugal separation water/sewage treatment, earth square drilling and mining, etc., can solve the problems of weak processing capacity and insufficient processing capacity of the processing system, and achieve significant comprehensive benefits , Reduce energy consumption, reduce the effect of conveying volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

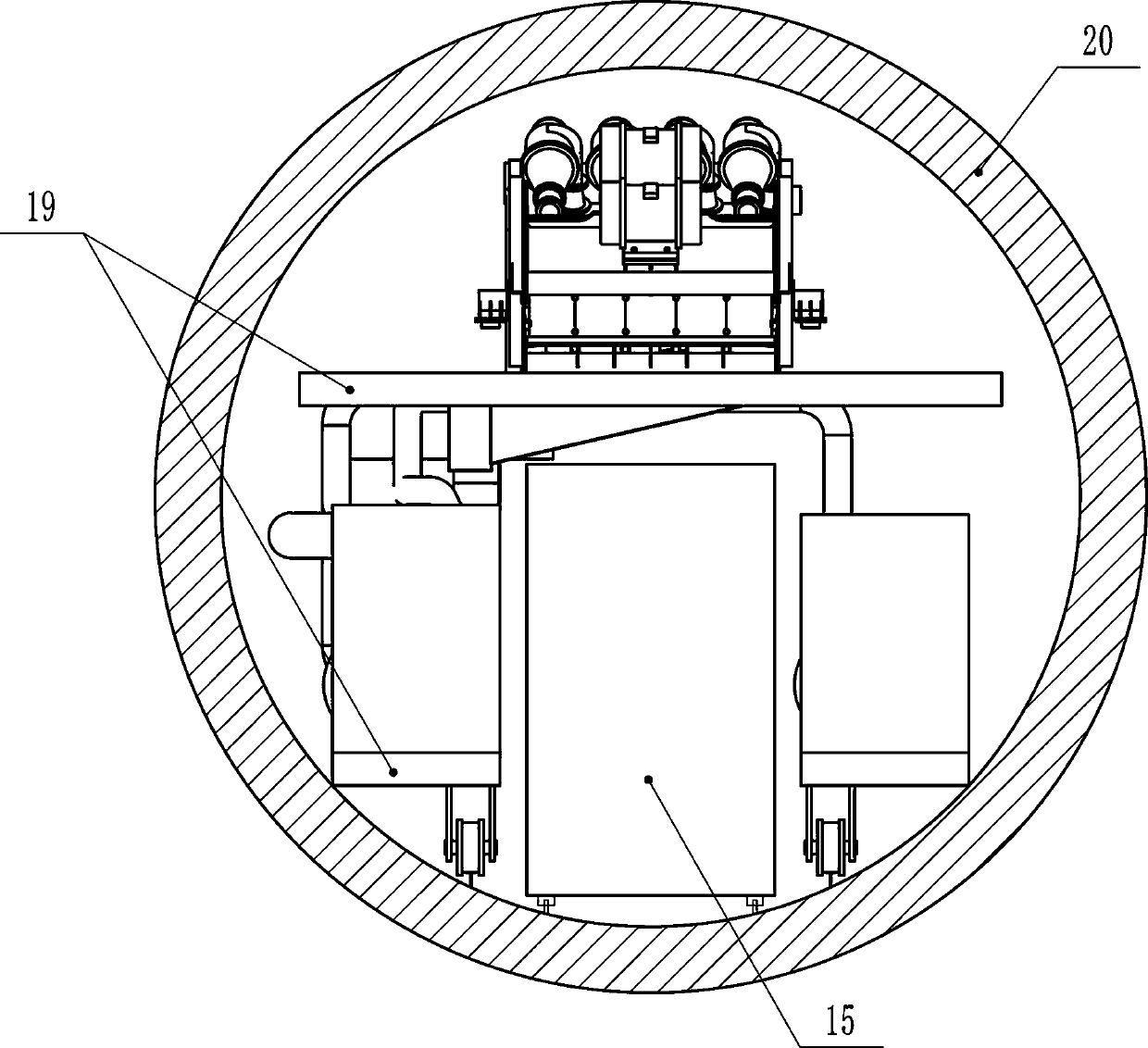

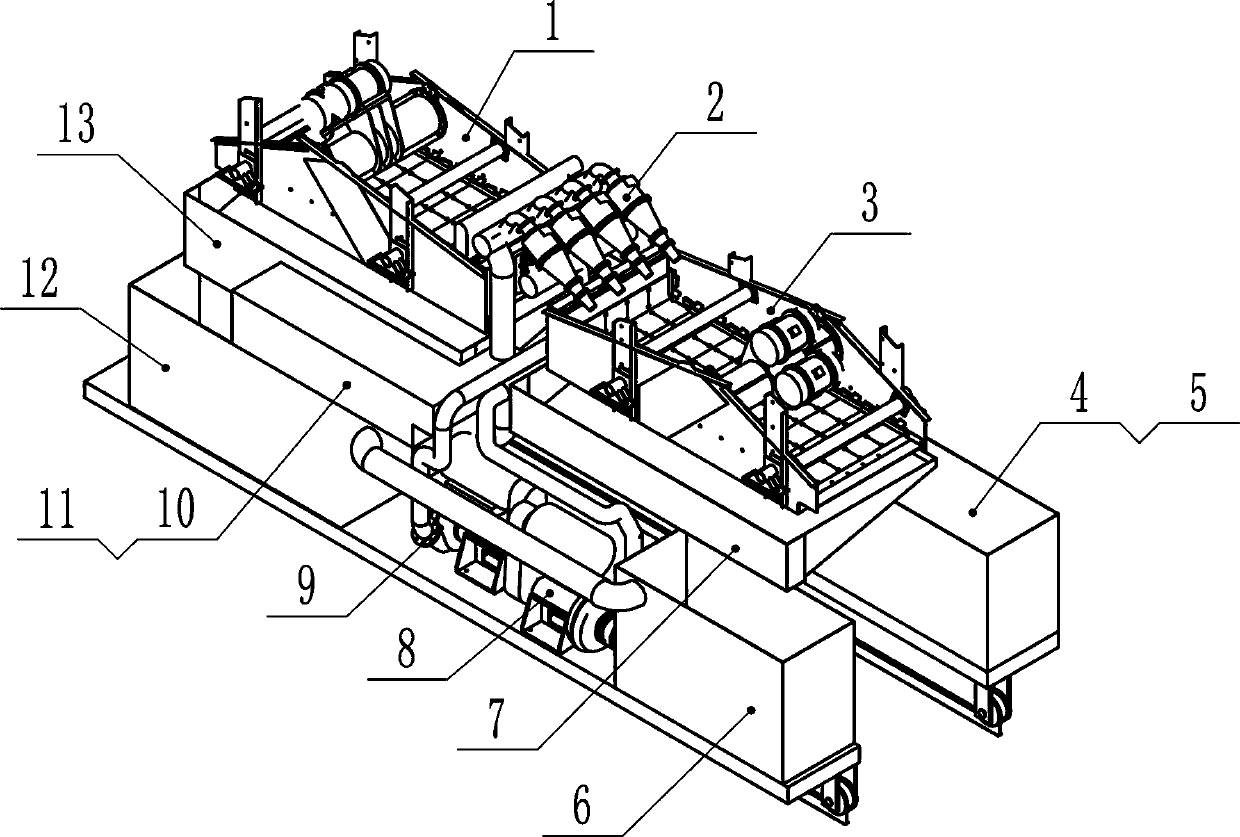

[0034] Such as Figure 1~3 Among them, a shield machine pull-type solid-liquid separation system includes a trolley frame 19 arranged behind the shield machine, and the trolley frame 19 is provided with a solid-liquid separation system;

[0035] The structure of the solid-liquid separation system is that the underscreen of the prescreen 1 is connected with the inlet of the cyclone 2, the heavy phase outlet of the cyclone 2 is connected with the dewatering screen 3, and the underscreen of the dewatering screen 3 is connected with the slurry storage tank. 12 connections;

[0036] The slurry storage tank 12 is connected with the inlet of the cyclone 2;

[0037] The supernatant outlet of the cyclone 2 is connected with the overflow box 10, and the overflow port of the overflow box 10 is connected with the clean slurry tank 6, and the clean slurry tank 6 is provided with a second sewage pump 8 to return the clean slurry to the shield structural system;

[0038] The oversize of t...

Embodiment 2

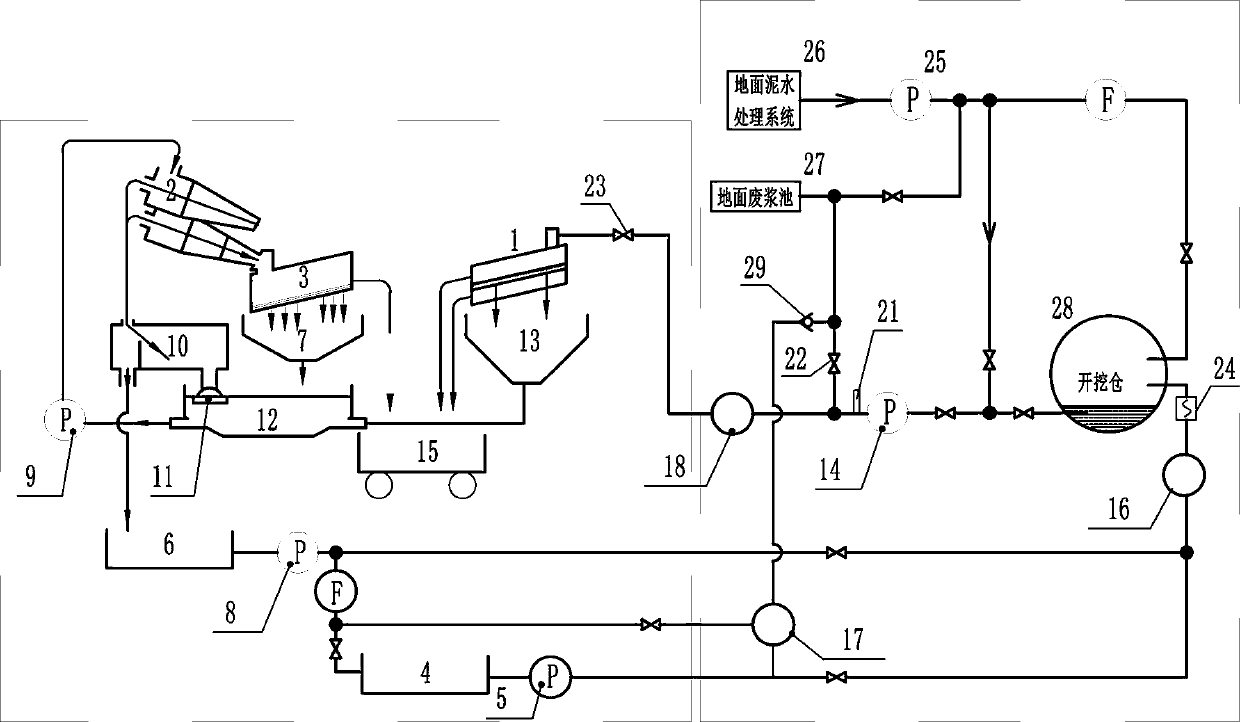

[0052] A separation method using the above-mentioned shield machine towed solid-liquid separation system, comprising the following steps:

[0053] S1, detect the viscosity of the mud through the online viscosity sensor 21;

[0054] S2. When the mud viscosity exceeds the preset value, the first stop valve 22 is opened, the second stop valve 23 is closed, and the mud is transported to the ground mud water treatment system 26, and then sent to the excavation bin 28 after being processed by the ground mud water treatment system 26;

[0055] When the viscosity of the mud is lower than the preset value, close the first shut-off valve 22, open the second shut-off valve 23, and transport the mud to the solid-liquid separation system, and send it to the excavation bin 28 after being processed by the solid-liquid separation system; , make full use of the processing capacity of the trailer-type solid-liquid separation system.

[0056] S3. Prioritize the use of the clean slurry processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com