A tower type extraction device for separating hydrocarbons in oily sludge by using supercritical carbon dioxide

A hydrocarbon and carbon dioxide technology, applied in the fields of sludge treatment, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of complex extraction equipment, reduced oily sludge treatment cost, complicated operation, etc., and achieve savings Extraction time and equipment space, ensure mobile processing while drilling, and simplify the effect of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

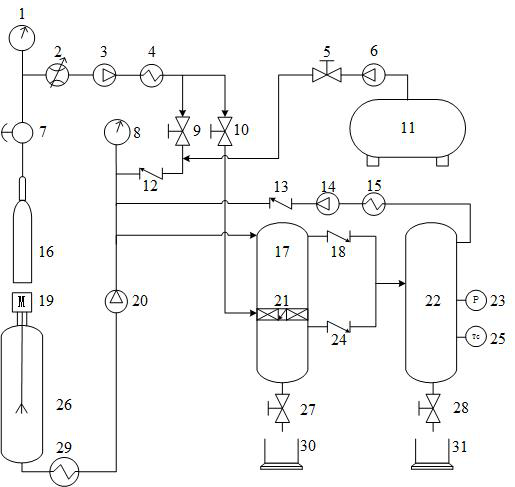

[0017] The first step: open the second valve 9, the third valve 10, close the first valve 5, the fourth valve 27, the fifth valve 28;

[0018] The second step: open the pressure reducing valve 7, the gas mass flow controller 2, the first gas compressor 3, and the first heat exchanger 4, pressurize and heat the carbon dioxide gas to a supercritical state and inject it into the system, and pass the first pressure Table 1 monitors the pressure change of carbon dioxide injected into the system;

[0019] The third step: after the supercritical carbon dioxide is injected into the system, the motor 19 is turned on, and the oil-containing solid waste is stirred into uniform solid-phase particles;

[0020] The 4th step: open the 3rd heat exchanger 29, be adjusted to the required temperature, open the booster pump and inject the oily solid waste after pressurization, heating into the continuous extraction tower 17 and mix with the supercritical carbon dioxide provided by the gas supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com