Compression system for recovering associated gas and method for compressing gas using the compression system

A compression system and associated gas technology, applied in liquefaction, solidification, lighting and heating equipment, etc., can solve the problems of high cost and long production cycle, and achieve the effect of low cost, small space occupation and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

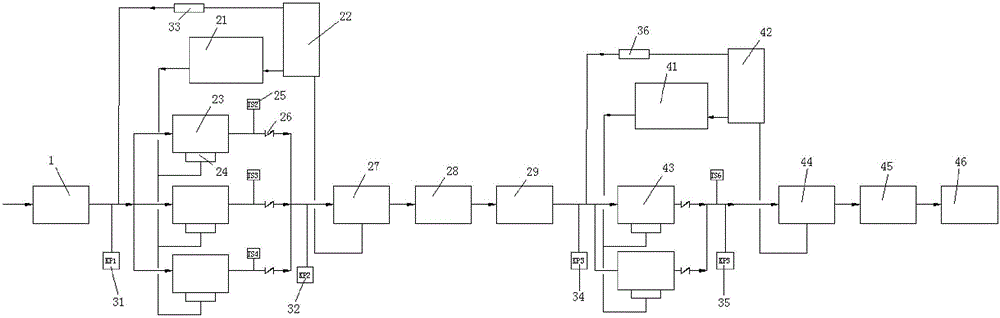

[0044] see figure 1 , this embodiment provides a compression system for recovery of associated gas, including a primary compression device, an oil separator I27, a heat exchanger I28, a gas-liquid separator I29, a secondary compression device, an oil separator II44, and a heat exchanger II45 , gas-liquid separator II46 and an oil return device that can automatically replenish oil for the first-stage compression device and the second-stage compression device, the first-stage compression device, the oil separator I27, and the heat exchanger I28 , the gas-liquid separator I29, the secondary compression device, the oil separator II44, the heat exchanger II45 and the gas-liquid separator II46 are connected in sequence, and the oil return device is respectively connected to the oil The separator I27, the oil separator II44, the primary compression device, and the secondary compression device are connected.

[0045] Further, the primary compression device includes at least two compr...

Embodiment 2

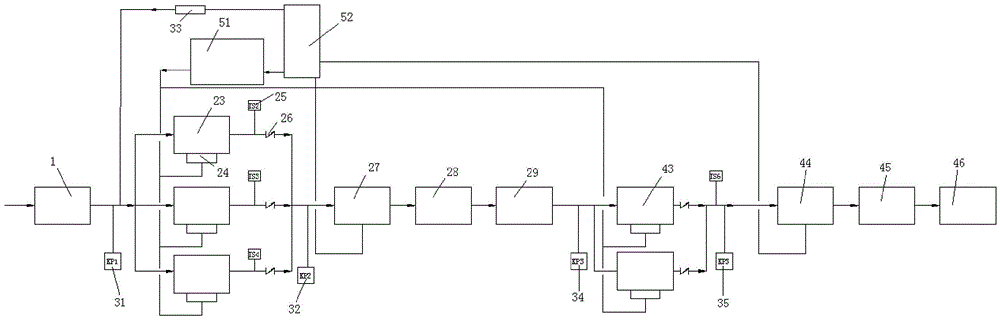

[0063] see figure 2 , this embodiment provides a compression system for associated gas recovery, the difference between this embodiment and Embodiment 1 is:

[0064]The oil return device includes an oil storage barrel 52 and an oil cooler 51, the oil storage barrel 52 is respectively connected with the oil separator I27, the oil separator II44, and the oil cooler 51, and the oil cooling The device 51 is connected with the compressor I23 and the compressor II43, the oil separator I27 is provided with a float valve I, the oil separator II44 is provided with a float valve II, the compressor I23 and the The compressor II43 is provided with an oil return float valve respectively.

[0065] Further, the oil storage barrel 52 is provided with a pressure relief valve 33 . Setting the pressure relief valve 33 on the oil storage tank 52 can prevent the pressure in the oil storage tank 52 from being too high, causing the oil in the oil separator I27 and oil separator II44 to be unable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com