Bimodal high density polyethylene and production process thereof

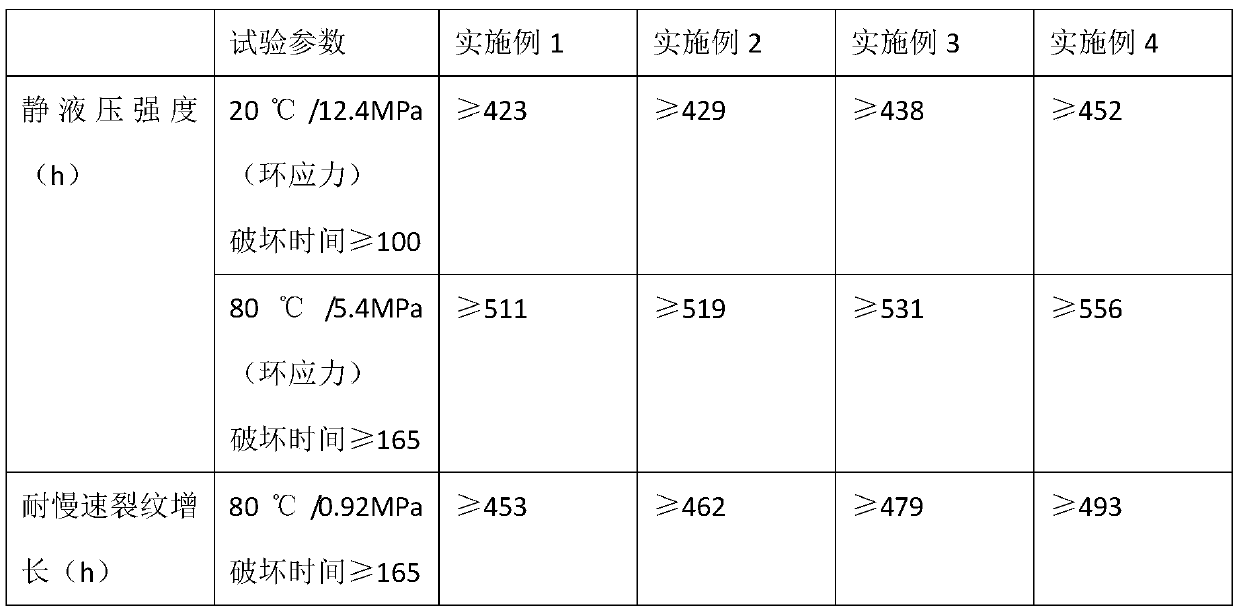

A high-density polyethylene and production technology technology, applied in the field of gas-phase fluidized bed production technology, can solve the problems of low polymerization efficiency and uncontrollable composition, and achieve high polymer yield, good hydrostatic strength, good slow speed resistance. Effect of crack growth properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of bimodal high-density polyethylene, comprises the steps:

[0024] Said bimodal high density polyethylene is prepared by contacting ethylene and at least one (C4-C20) alpha-olefin with a bimodal catalyst in a single gas phase reactor in the presence of hydrogen and an induced condensing agent (ICA); wherein the polymerization The temperature is 50-120°C; the molar ratio of hydrogen to ethylene is 0.06-0.12, the molar ratio of comonomer to ethylene is 0.006-0.020, and the amount of induced condensing agent accounts for 5-30 mol% of the total reactor amount.

[0025] comonomer

[0026] (C4-C20) α-olefins are linear or branched α-olefins having 4-20 carbon atoms, and exemplary α-olefins that can be used as comonomers in the present invention may include, but are not limited to, 1 -butene, 1-pentene, 1-hexene, 1-heptene, 1-octene, 4-methyl-1-pentene, 1-decene, 1-dodecene, etc., and any combination thereof ; preferably 1...

Embodiment

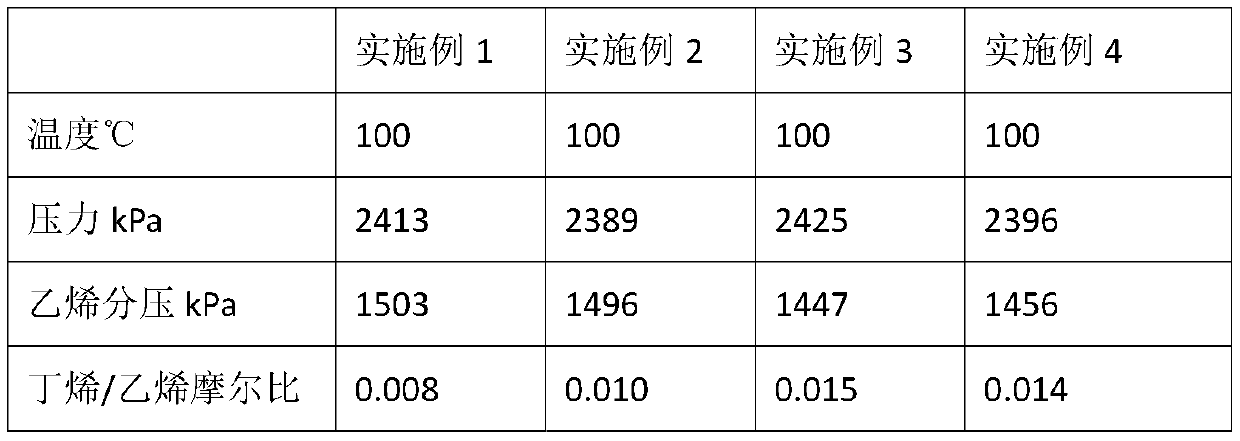

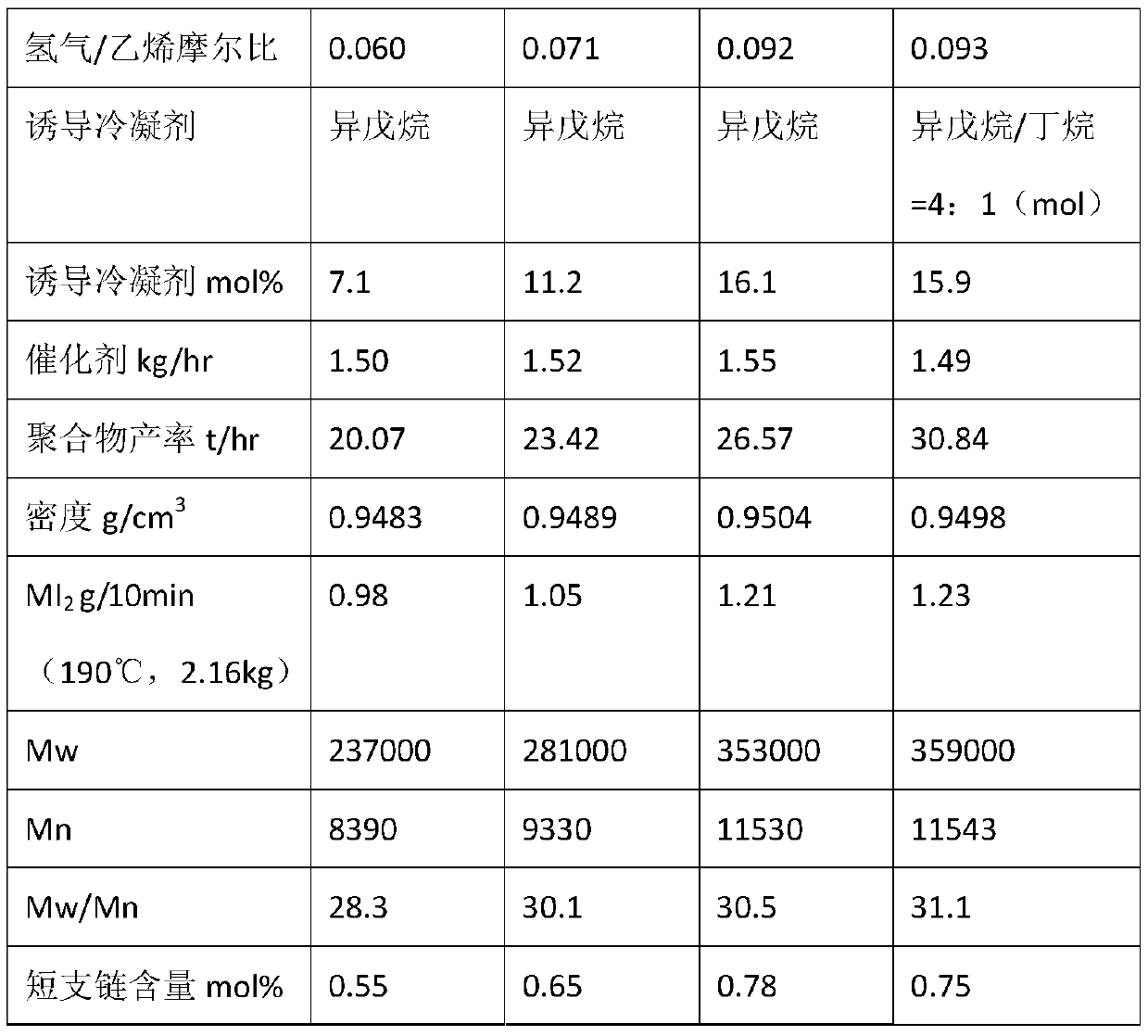

[0063] Polymerization was carried out in a gas phase fluidized bed reactor. The fluidized bed reactor is configured with multiple gas feed inlets and catalyst feed inlets and product discharge outlets. The polymerization reaction uses bimodal slurry catalyst BMC-200, ethylene, 1-butene, induced condensing agent, H 2 . First, the gaseous atmosphere in the reactor containing the preloaded seedbed was dried using high-purity anhydrous molecular nitrogen, and then ethylene, 1-hexene, hydrogen, and induced condensing agent were introduced according to the amounts and ratios listed in Table 1. The gas phase conditions were established to the desired operating gas phase conditions while heating the reactor to the polymerization temperature for maintenance; then the bimodal slurry catalyst BMC-200 was fed into the reactor for polymerization. The bimodal high density polyethylene of the present invention was collected from the product discharge and characterized.

[0064] Table 1: T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com