Aluminum-silicon electronic packaging material and preparation method thereof

An electronic packaging material, aluminum-silicon technology, applied in transportation and packaging, metal processing equipment, etc., can solve the problems of lower yield, easy cracking, high cost, etc., and achieve high density, high sphericity, and controllable particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) An Al-Si alloy powder with a Si content of 20 wt % and a particle size of 1-2 μm prepared by gas atomization is recorded as an Al-20% Si alloy gas atomized powder with a particle size of 1-2 μm.

[0063] (2) Put the Al-Si alloy powder into a rubber sheath, and perform cold isostatic pressing after vibration. The isostatic pressing pressure is 120MPa, and the holding time is 200s.

[0064] (3) Heat the cold isostatic pressed compact, extrusion die and extrusion barrel to 430°C, hold for 0.5h, and perform hot extrusion with an extrusion ratio of 20:1 and an extrusion speed of 1mm / s to obtain aluminum-silicon electronics packaging material.

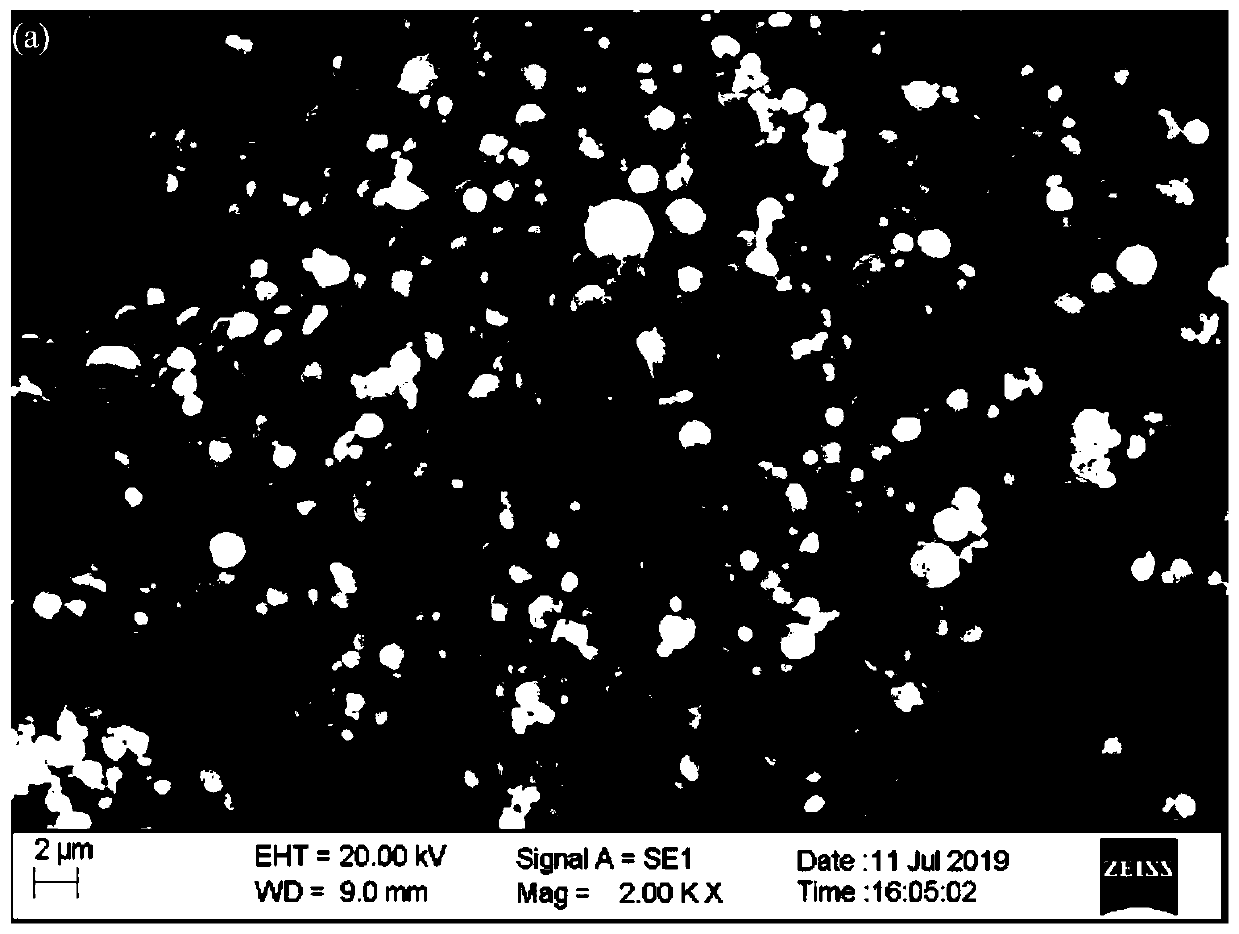

[0065] Fig. 1 (a) is the SEM image of the Al-20% Si alloy gas atomized powder with a particle size of 1-2 μm in Example 1, as can be seen from the figure, the Al-Si powder has a particle size of 1-2 μm, good sphericity, No obvious defects.

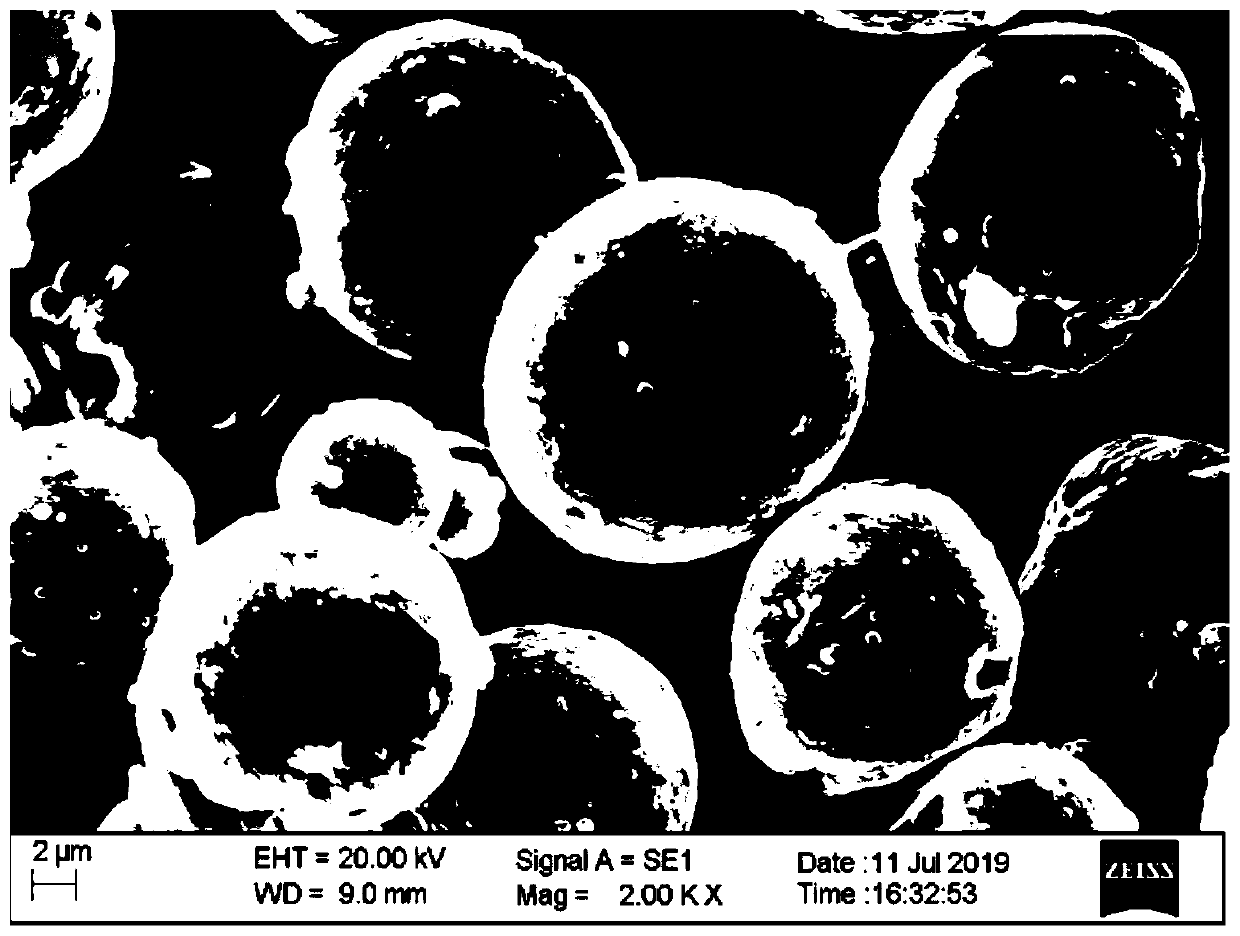

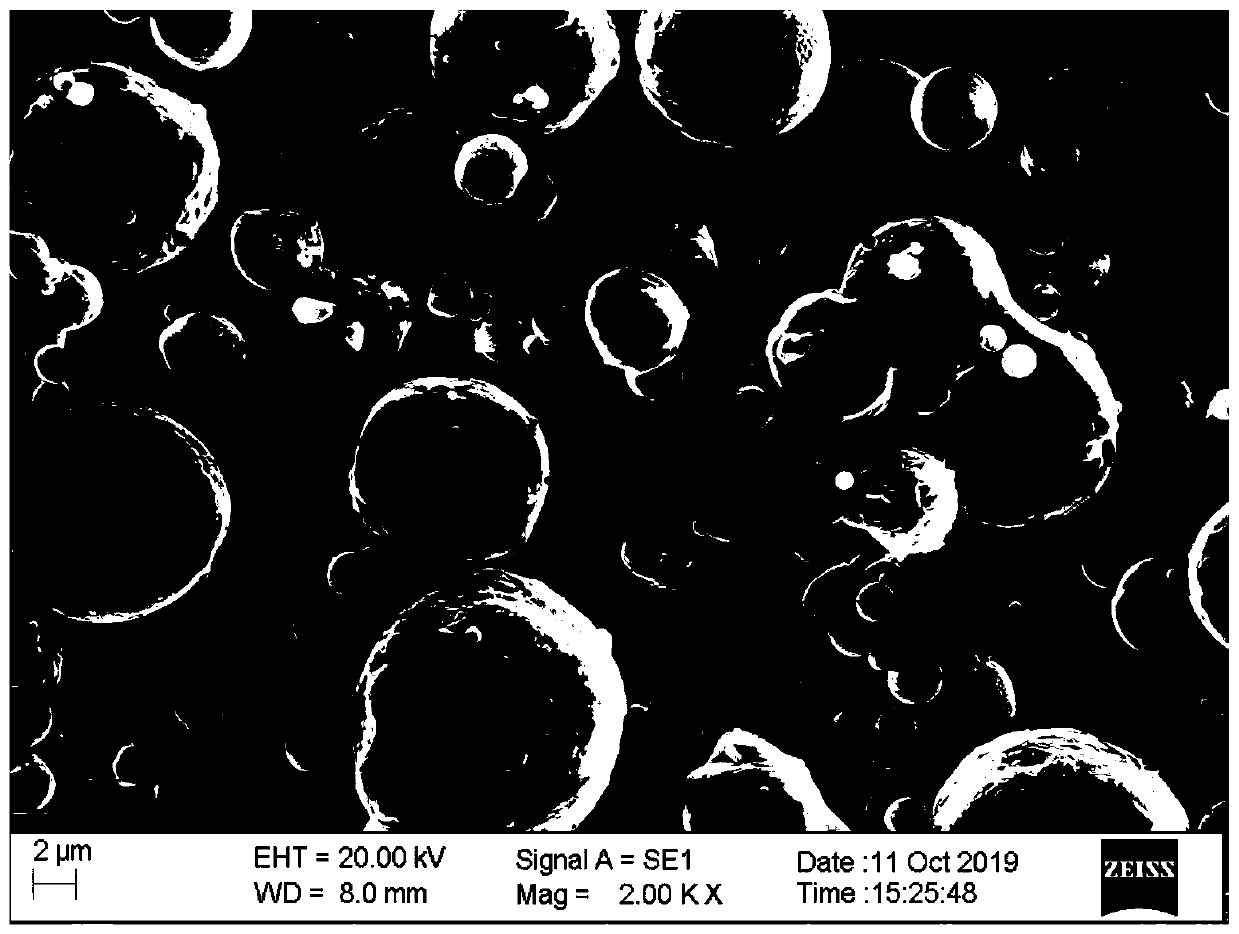

[0066] Figure 2(a) is the SEM image of the aluminum-silicon electronic packaging materia...

Embodiment 2

[0068] (1) An Al-Si alloy powder with a Si content of 20wt% and a particle size of 20-25 μm prepared by gas atomization is recorded as an Al-20% Si alloy gas atomized powder with a particle size of 1-2 μm.

[0069] (2) Put the Al-Si alloy powder into a rubber sheath, and perform cold isostatic pressing after vibration. The isostatic pressing pressure is 120MPa, and the holding time is 200s.

[0070] (3) Heat the cold isostatic pressed compact, extrusion die and extrusion barrel to 430°C, hold for 0.5h, and perform hot extrusion with an extrusion ratio of 20:1 and an extrusion speed of 1mm / s to obtain aluminum-silicon electronics packaging material.

[0071] Fig. 1 (b) is the SEM image of the Al-20% Si alloy gas atomized powder with a particle size of 20-25 μm in Example 2. As can be seen from the figure, the Al-Si powder has a particle size of 20-25 μm and better sphericity. No obvious defects.

[0072] Fig. 2(b) is the SEM image of the aluminum-silicon electronic packaging ...

Embodiment 3

[0076] (1) An Al-Si alloy powder with a Si content of 50 wt % and a particle size of 10-20 μm prepared by gas atomization is recorded as an Al-50% Si alloy gas atomized powder with a particle size of 10-20 μm.

[0077] (2) Put the Al-Si alloy powder into a rubber sheath, and perform cold isostatic pressing after vibration. The isostatic pressing pressure is 80MPa, and the holding time is 300s.

[0078] (3) Heat the cold isostatic pressed compact, extrusion die and extrusion cylinder to 350°C, keep it warm for 1h, and perform hot extrusion with an extrusion ratio of 60:1 and an extrusion speed of 3mm / s to obtain an aluminum-silicon electronic package Material.

[0079] Fig. 1 (c) is the SEM image of the Al-50% Si alloy gas atomized powder with a particle size of 10-20 μm in Example 3. As can be seen from the figure, the particle size of the Al-Si powder is 10-20 μm, and the sphericity is better. No obvious defects.

[0080] Figure 2(c) is the SEM image of the aluminum-silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap