A method for repairing moisture-proof layer of building wall with high relative humidity

A technology for building walls and repair methods, applied in building maintenance, construction, building components, etc., can solve the problem of lack of high relative humidity building wall moisture-proof layer repair methods, structural safety, hidden dangers of external wall waterproofing, changes in building structures, etc. problems, to achieve the effect of improving experience, simple operation and equipment requirements, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

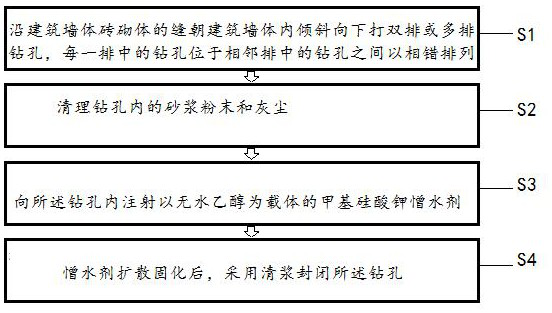

Method used

Image

Examples

Embodiment 1

[0070] A key cultural relic protection building was built in 1933

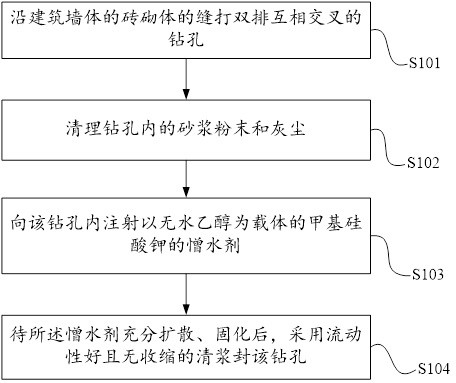

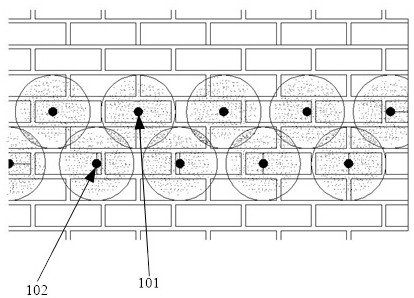

[0071] 1. Drill double rows of cross holes along the joints of the brick masonry. The inclination of the drilling holes is 30°, and the diameter of the drilling holes is preferably 15mm; the height of the drilling holes is 350mm from the ground, and the height of the last row of holes should be higher Ground at least 150mm. The hole spacing of the same row of double row cross punching is 200mm. The distance between the drilling holes is preferably 100mm.

[0072] 2. Use a vacuum cleaner to clean the dust in the hole.

[0073] 3. Inject the waterproofing agent diluted with ethanol into the hole to make it full.

[0074] 4. After 24 hours, the drilling should be sealed with hydraulic lime slurry or low-alkali cement slurry with good fluidity and no shrinkage.

[0075] By comparison, before restoration: the wall humidity range is 15-25%, and the average humidity is 21.2%; after treatment: the wall average hum...

Embodiment 2

[0077] A temple water stop and tide avoidance project

[0078] 1. Drill double rows of cross holes along the joints of the brick masonry. The inclination of the drilling holes is 30°, and the diameter of the drilling holes is preferably 15mm. Ground at least 150mm. The hole spacing of the same row of double row cross punching is 240mm. The distance between drilling holes is preferably 300mm.

[0079] 2. Use a vacuum cleaner to clean the dust in the hole;

[0080] 3. Inject water-repellent diluted with ethanol into the hole to make it full;

[0081] 4. After 24 hours, the drilling should be sealed with hydraulic lime slurry or low-alkali cement slurry with good fluidity and no shrinkage.

[0082] After treatment: the phenomenon of dampness on the wall is obviously weakened.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com