Yaw structure of wind generating set

A wind turbine and yaw technology, which is applied to wind turbines, wind turbine control, wind power generation, etc., can solve the problems of difficult replacement, bolt damage, high cost, etc., to increase the clamping length of bolts and increase the number of layouts , easy replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

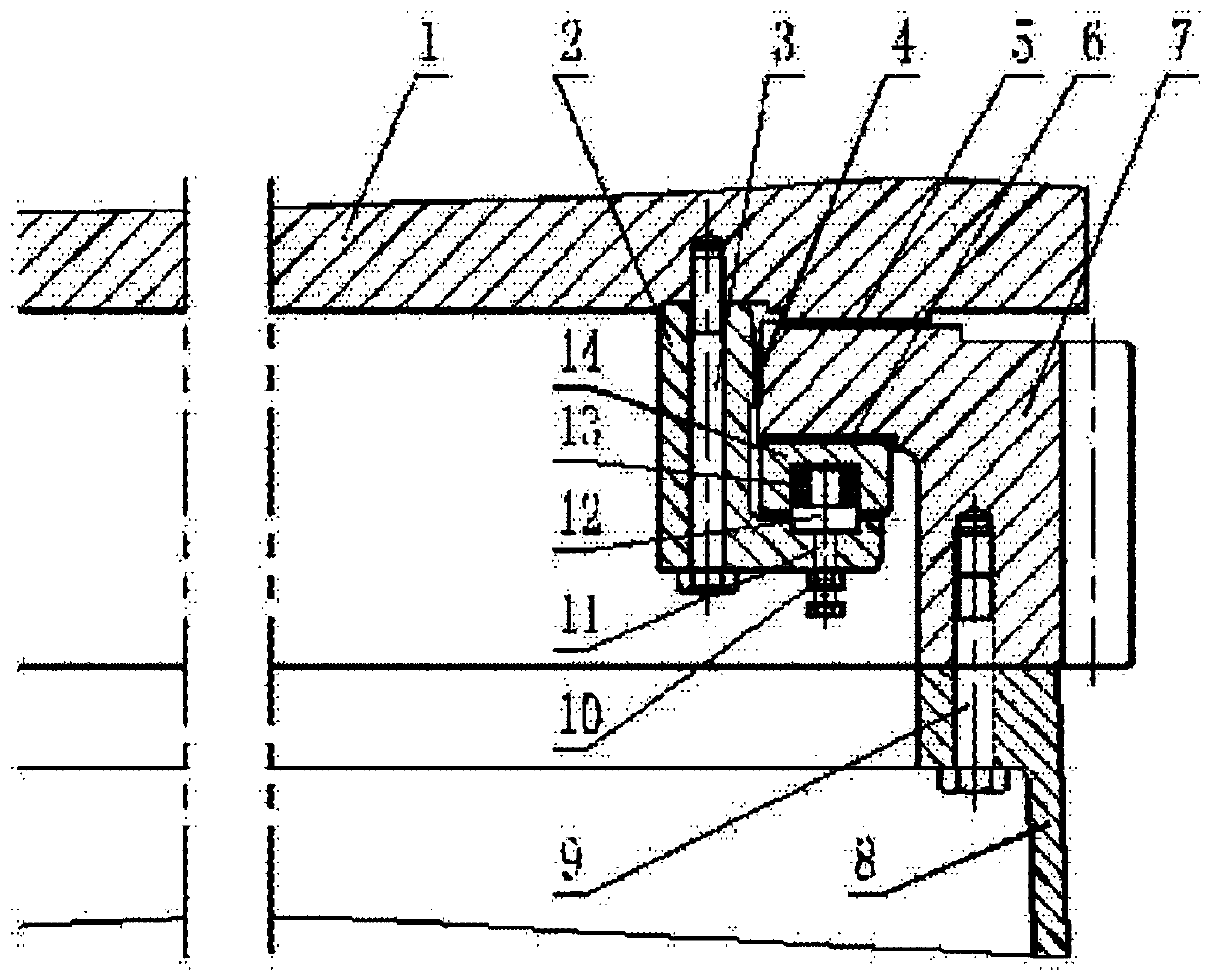

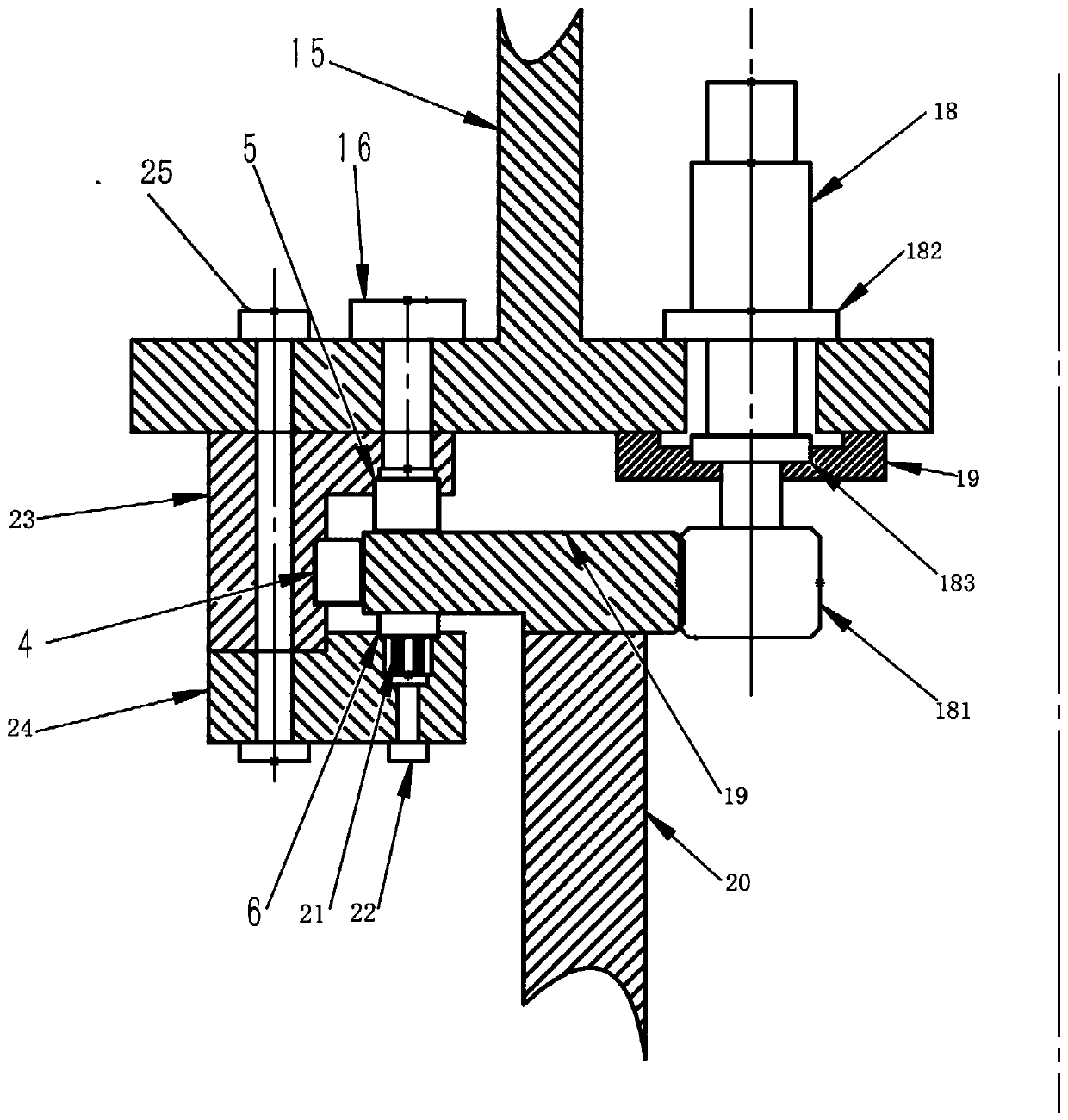

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 2 As shown, the invention includes nacelle 15 , yaw ring gear 19 , brakes, yaw drive 18 and tower 20 . A plurality of yaw drives 18 are arranged on the bottom plate of the nacelle 15, and the nacelle 15 and the yaw drives 18 are fixedly connected by bolts. The bottom of the nacelle 15 is equipped with a lower bracket 19 by bolts, and the lower bracket 19 is arranged corresponding to the yaw drive 18. The bottom plate of the nacelle 15 and the lower bracket 19 are provided with a through hole for the yaw drive 18 to pass through. The holes are stepped holes. The yaw drive 18 is provided with an upper flange 182 and a lower flange 183, the upper flange 182 is fixedly connected with the nacelle 15 by bolts, and the lower flange 183 is placed on the step surface of the through hole of the lower bracket 19 superior. In this way, the yaw drive 18 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com