Thermal power plant unmanned inspection task planning method and system

A technology for inspection tasks and inspection systems, applied in control/regulation systems, non-electric variable control, measurement devices, etc., can solve problems such as missed inspections, undetected systems, and formulations, etc., to improve efficiency and reliability. performance, preventing further expansion of failures, and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

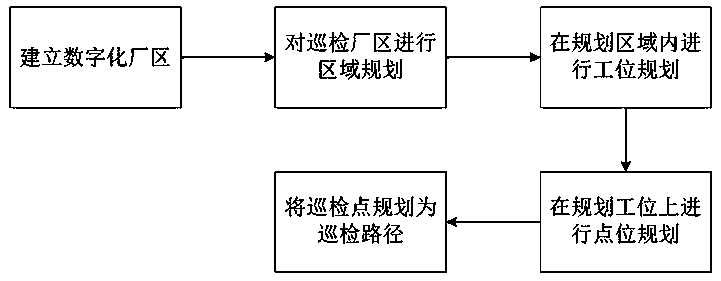

[0041] Embodiment 1: as figure 1 It is an overall flowchart of an unmanned patrol inspection task planning method for a thermal power plant of the present invention. Before the patrol inspection system executes the patrol inspection task, the operation and maintenance personnel perform task planning according to the task planning method of the present invention.

[0042] A thermal power plant unmanned inspection task planning method, characterized in that the task planning method comprises the following steps:

[0043] Step 1: Establish a digital factory area: According to the design and installation drawings of the factory area and each equipment in the plant area combined with the results of on-site surveying and mapping, draw a 3D model of the plant area and each equipment in the plant area through 3D graphics software, and record the structural characteristics of the plant area and equipment with the digital model , including the building structure of the plant, the layout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com