Lutein laying hen feed and preparation method thereof

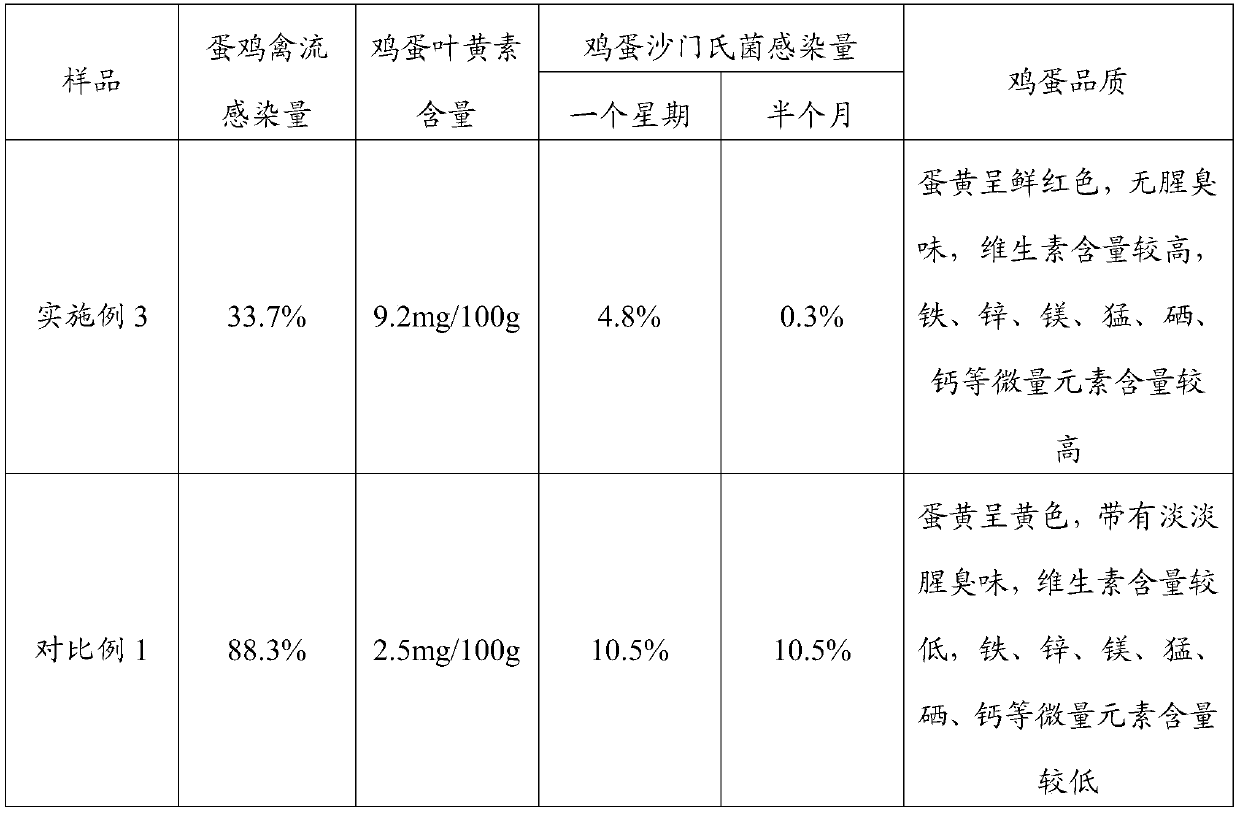

A technology for laying hen feed and lutein, applied in the field of chicken feed, can solve problems such as food poisoning, and achieve the effects of improving utilization rate, curbing salmonella, and enhancing immune function of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

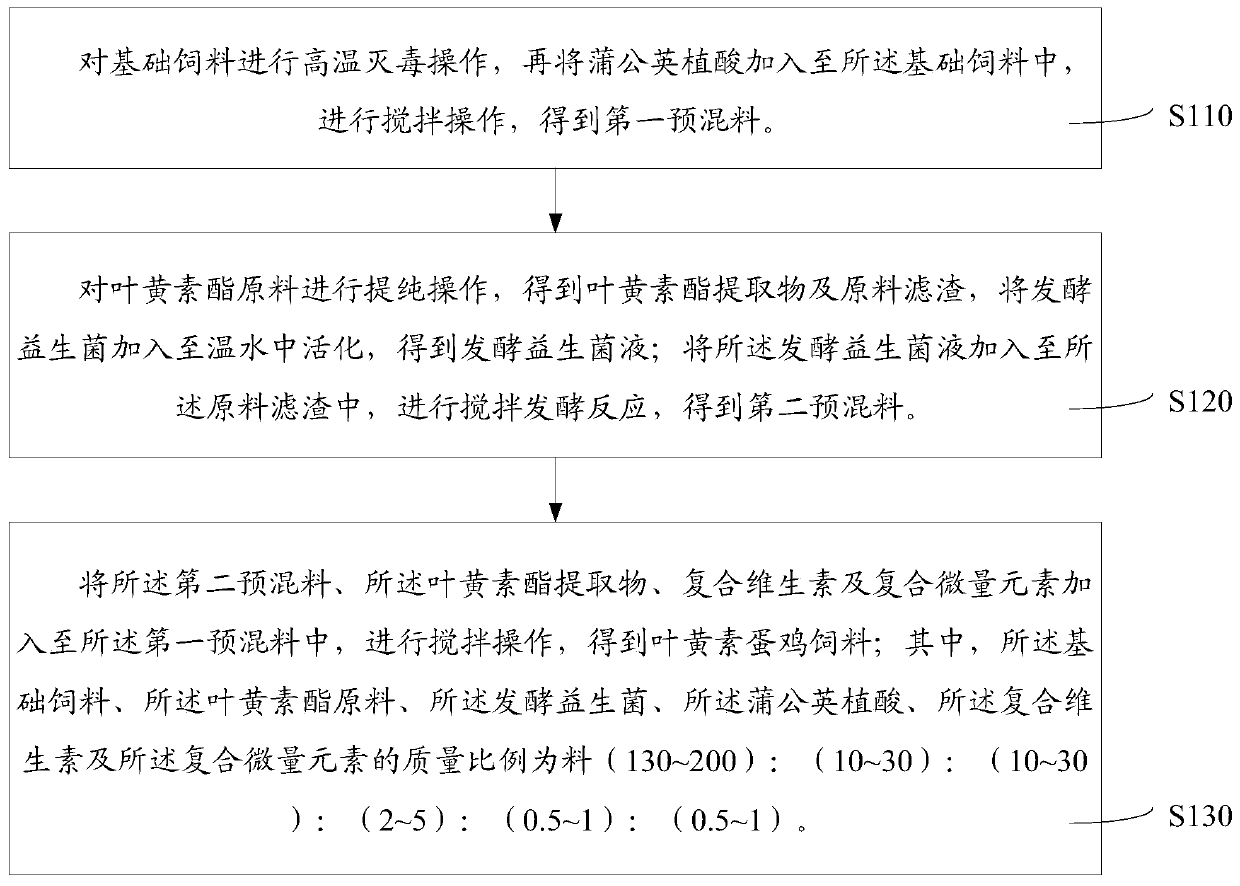

[0027] For an implementation, see figure 1 , a preparation method of lutein laying hen feed, comprising the following steps:

[0028] S110, performing a high-temperature sterilization operation on the basic feed, then adding dandelion phytic acid into the basic feed, and performing a stirring operation to obtain a first premixed material.

[0029] S120, purifying the lutein ester raw material to obtain lutein ester extract and raw material filter residue, adding fermented probiotics into warm water for activation to obtain a fermented probiotic liquid; adding the fermented probiotic liquid to the In the filter residue of the raw material, a stirring fermentation reaction is carried out to obtain a second premixed material.

[0030] S130, adding the second premix, the lutein ester extract, multivitamins and compound trace elements to the first premix, and performing stirring operation to obtain lutein feed for laying hens; wherein , the mass ratio of the basic feed, the lutei...

Embodiment 1

[0049]S111, at a temperature of 100°C, perform a high-temperature sterilization operation on 164 kg of basic feed, then add 2 kg of dandelion phytic acid into the basic feed, and perform a stirring operation to obtain a first premix; wherein the basic feed Including cassava flour 50kg, corn 70kg, soybean meal 20kg, wheat bran 10kg, soybean oil 3kg, shell powder 10kg, salt 1kg.

[0050] S121, purifying 30 kg of lutein ester raw material to obtain lutein ester extract and raw material filter residue, adding 30 kg of fermented probiotics into warm water for activation to obtain a fermented probiotic liquid; adding the fermented probiotic liquid to In the filter residue of the raw material, at a temperature of 30°C, carry out a stirring fermentation reaction for 24 hours to obtain a second premix; wherein, for example, the raw material of lutein ester includes marigold, cabbage, celery, cauliflower, asparagus , alfalfa, lettuce, carrot and corn; the fermented probiotics include Cl...

Embodiment 2

[0053] S112, at a temperature of 150°C, perform a high-temperature sterilization operation on 167 kg of the basic feed, then add 5 kg of dandelion phytic acid into the basic feed, and perform a stirring operation to obtain a first premix; wherein the basic feed Including cassava flour 70kg, corn 50kg, soybean meal 30kg, wheat bran 5kg, soybean oil 5kg, shell powder 5kg, salt 2kg.

[0054] S122, purifying 10 kg of lutein ester raw material to obtain lutein ester extract and raw material filter residue, adding 10 kg of fermented probiotics into warm water for activation to obtain a fermented probiotic liquid; adding the fermented probiotic liquid to In the filter residue of the raw material, a stirring fermentation reaction was carried out at a temperature of 42° C. for 12 hours to obtain a second premix; wherein, for example, the lutein ester raw material includes marigold, cabbage, celery, cauliflower, and asparagus , alfalfa, lettuce, carrot and corn; the fermented probiotics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com