Method for preparing cigarette filter stick aroma enhancement pellets by using thin and short tobacco stems

A technology for cigarette filter rods and tobacco stems, which is applied in the field of preparing flavoring pellets for cigarette filter rods, and achieves the effects of large surface area, mild reaction conditions and large biological load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

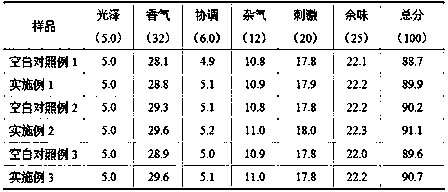

Embodiment 1

[0023] Embodiment 1: The method for preparing cigarette filter stick flavoring pellets by using thin and short tobacco stems in this embodiment comprises the following steps:

[0024] 1. Tobacco stem screening and crushing: Sieve K326 flue-cured tobacco, Hongda flue-cured tobacco, Yunyan 87 flue-cured tobacco, oriental tobacco, and Dabai No. 1 Burley tobacco stems with a sieving vibrating sieve, and the diameter of the sieve is less than 2mm , the tobacco stems with a length of less than 35 mm are crushed after sieving to make 600-800 mesh thin and short tobacco stem superfine powder;

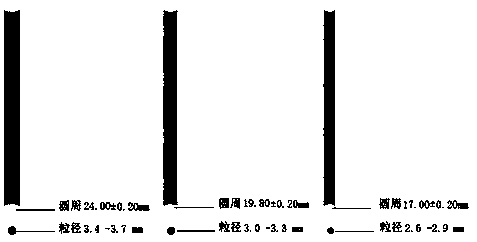

[0025] 2. Carrier screening: Ultrasonic cleaning of food-grade lightweight porous ceramsite balls at a temperature of 25°C for 50 minutes, drying with hot air at 80°C, and selection of particles with a particle size range of 3.4 to 3.7mm as carriers;

[0026] 3. Carrier activation: Mix food-grade light porous ceramsite and activation buffer at a mass ratio of 1:4, activate for 12 hours, and the...

Embodiment 2

[0032] Embodiment 2: The method for preparing cigarette filter stick flavoring pellets by using thin and short tobacco stems in this embodiment comprises the following steps:

[0033] 1. Tobacco stem screening and crushing: Sieve K326 flue-cured tobacco, Hongda flue-cured tobacco, Yunyan 87 flue-cured tobacco, oriental tobacco, and Dabai No. 1 Burley tobacco stems with a sieving vibrating sieve, and the diameter of the sieved ones is less than 2mm , the tobacco stems with a length of less than 35mm are crushed after sieving to make 600-700 mesh thin and short tobacco stem superfine powder;

[0034] 2. Carrier screening: Ultrasonic cleaning of food-grade lightweight porous ceramsite balls at a temperature of 30°C for 45 minutes, then drying with hot air at 90°C, and selecting particles with a particle size range of 3.0-3.3mm as carriers;

[0035] 3. Carrier activation: mix food-grade light porous ceramsite and activation buffer at a mass ratio of 1: 2, activate for 18 hours, an...

Embodiment 3

[0041] Embodiment 3: The method for preparing cigarette filter stick flavoring pellets by using thin and short tobacco stems in this embodiment includes the following steps:

[0042] 1. Tobacco stem screening and crushing: Sieve the stems of K326, Hongda flue-cured tobacco, Yunyan 87 flue-cured tobacco, oriental tobacco, and Dabai No. 1 Burley tobacco with a sieving vibrating sieve, and the diameter of the sieved ones is less than 2mm. Tobacco stems with a length of less than 35 mm are crushed after sieving to make ultrafine powder of 700-800 mesh short tobacco stems;

[0043] 2. Carrier screening: Ultrasonic cleaning of food-grade lightweight porous ceramsite balls at a temperature of 40°C for 35 minutes, and then drying with hot air at 100°C, and selecting particles with a particle size range of 2.6 to 2.9mm as carriers;

[0044] 3. Carrier activation: Mix food-grade light porous ceramsite and activation buffer at a mass ratio of 1: 1.5, activate for 24 hours, and then dry w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com