Steam turbine blade blank forging machine

A technology for steam turbine blades and forging machines, which is applied in the field of forging machines and can solve the problems of inability to clamp and fix the blank of steam turbine blades, and inability to clean oxide scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

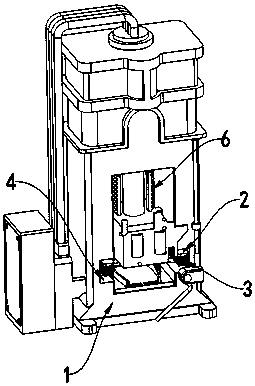

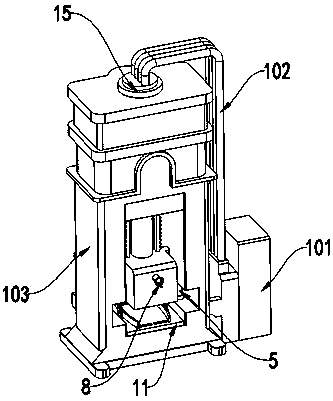

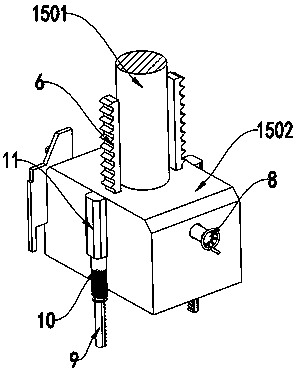

[0030] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a steam turbine blade blank forging machine, including a forging device 1, a hydraulic device 15 is installed on the inner side of the forging device 1, and the hydraulic device 15 includes a hydraulic rod 1501 and a stamping head 1502, the hydraulic rod 1501 A stamping head 1502 is installed at the lower end, and a connecting shell 11 is installed at the lower end inside the forging device 1, and slots 12 are arranged on both sides of the upper end surface of the connecting shell 11;

[0031] The first rack 6 is installed on both sides of the upper end of the stamping head 1502, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com