Powder metallurgy production line and production process

A powder metallurgy and production line technology, applied in the field of metallurgical production and processing, can solve the problems of increasing processing cost, rough outer surface, wasting time, etc., and achieve the effect of improving processing efficiency and improving screening ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

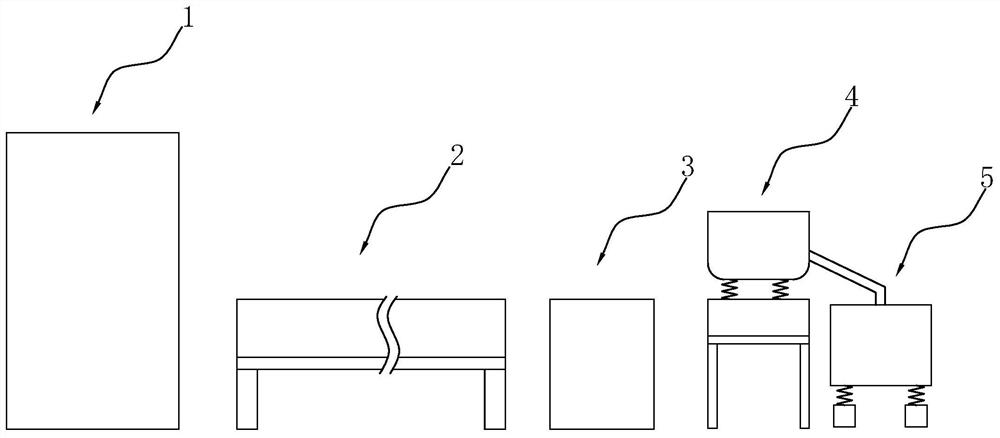

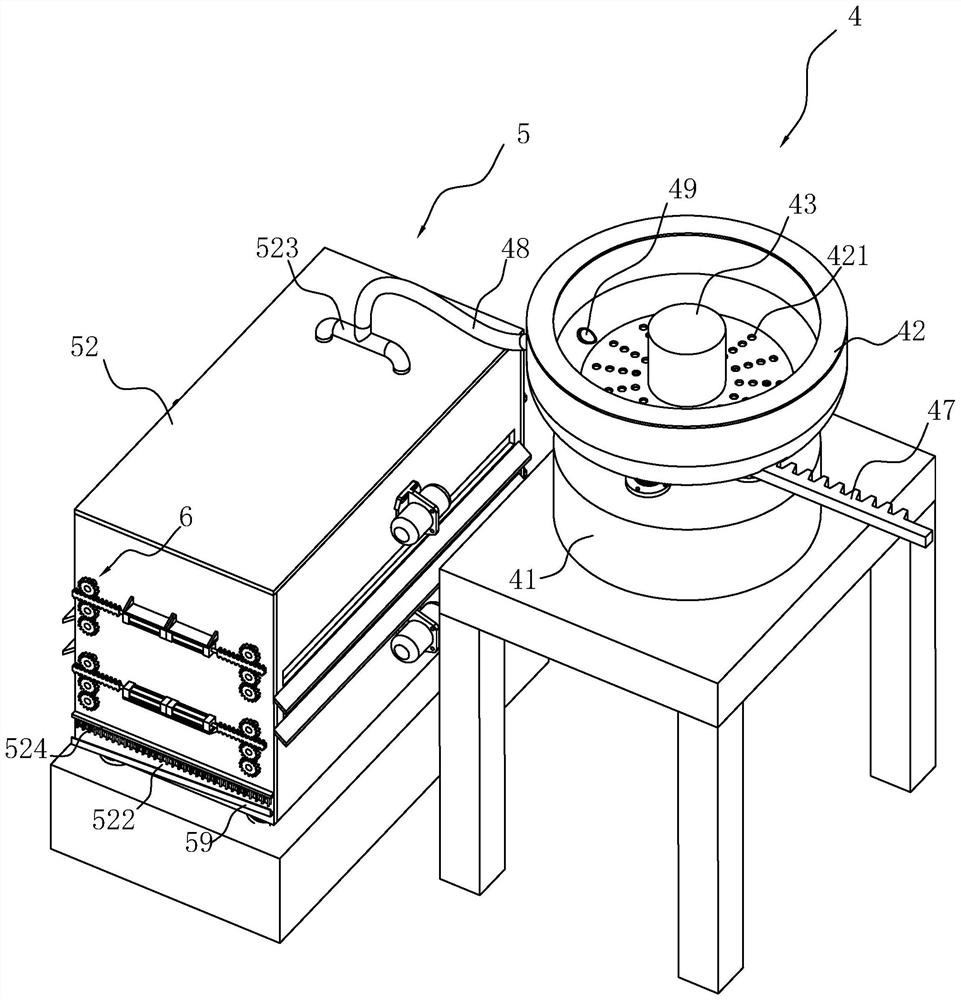

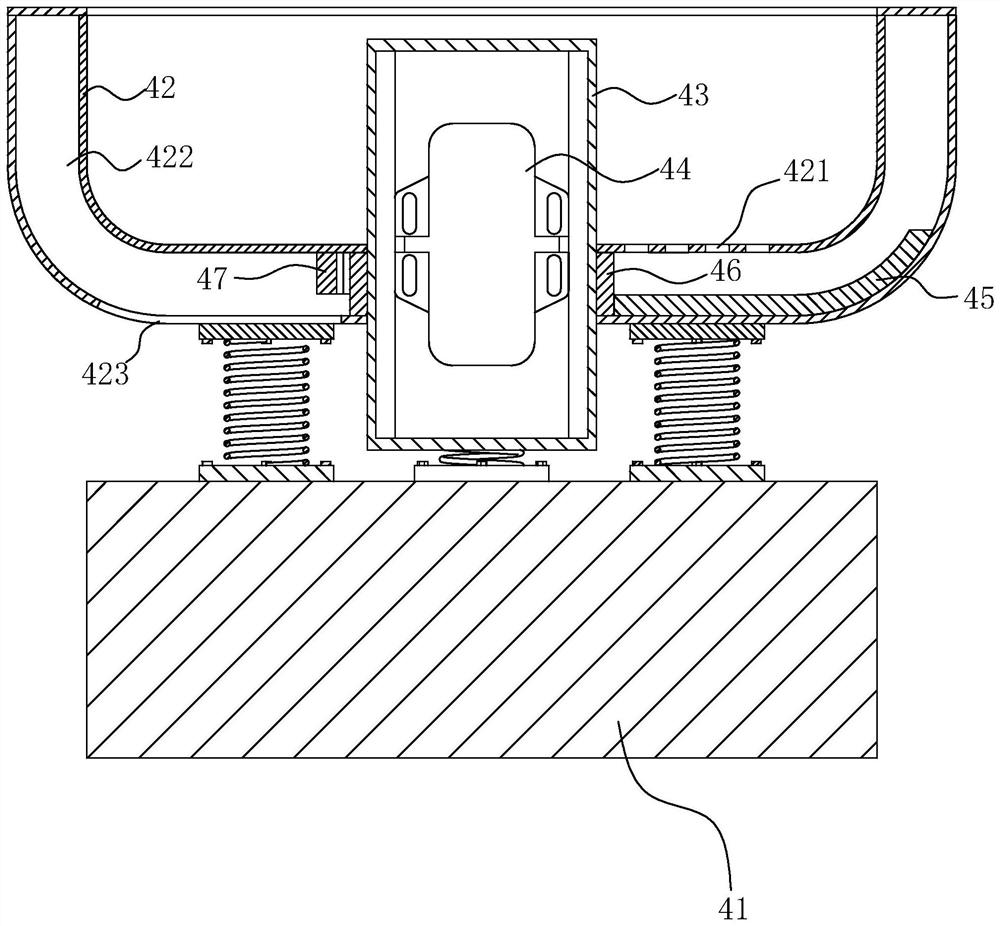

[0037] Embodiment 1: Reference figure 1, a powder metallurgy production line, including a powder hydraulic molding machine 1, a calciner 2, a cooling device 3, a vibration polishing machine 4 and a screening machine 5 arranged in sequence. First, after the metal powder is configured, it is extruded into a corresponding shape through the powder hydroforming machine 1 and a customized mold, and then a conveyor belt is set between the powder hydroforming machine 1 and the calciner 2, and the workpiece is transferred to the calciner through the conveyor belt Calcination is carried out in 2 to eliminate the internal stress of the workpiece. The calcined workpiece is cooled by the cooling device 3, and then put into the vibration polishing machine 4 for polishing, so that the surface of the workpiece is bright, and finally passes through the screening machine 5, so that the workpiece and the steel ball can be separated. The cooling device 3 is a cooling box, which adopts water cool...

Embodiment 2

[0051] Embodiment two, a kind of powder metallurgy production process, comprises the following steps:

[0052] (1) Mix different metal powders evenly;

[0053] (2) Stamp the mixed metal powder into the shape of the product with a powder forming hydraulic press;

[0054] (3) After the product is formed, put the product into the calciner for sintering;

[0055] (4) Cool the product after sintering;

[0056] (5) The cooled product is put into a vibration polishing machine for polishing;

[0057] (6) The polished products are packaged and put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com