Spaceflight vehicle structure with ultra-light weight, large expansion-contraction ratio and ultra-low temperature working environment

A space vehicle and working environment technology, which is applied to space navigation vehicles, space vehicle heat protection devices, aircraft, etc., can solve the problems of high cost, small shape, and high quality ultra-low temperature heat-proof structure, and achieve low cost and excellent performance. The effect of large scale ratio and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

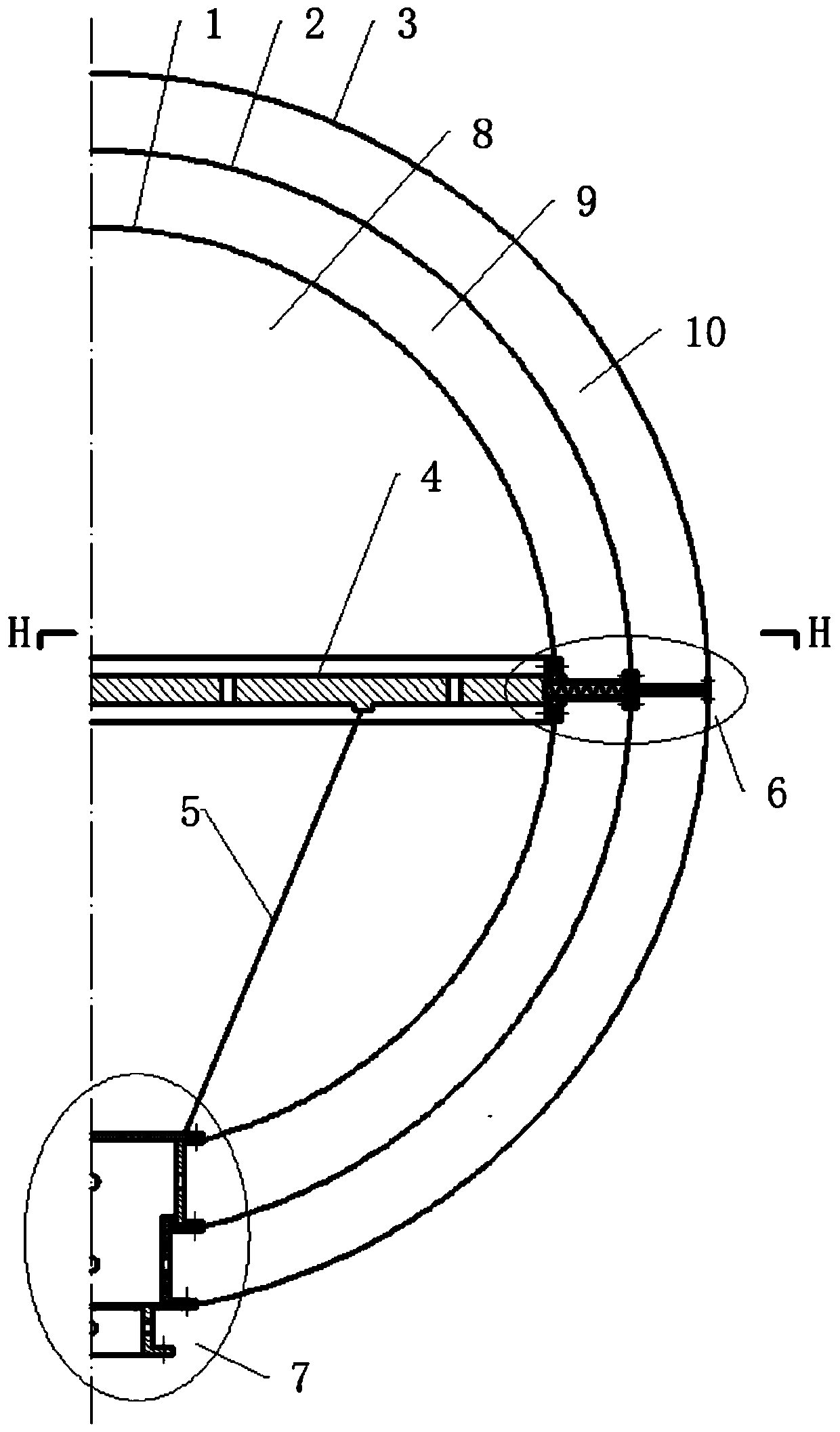

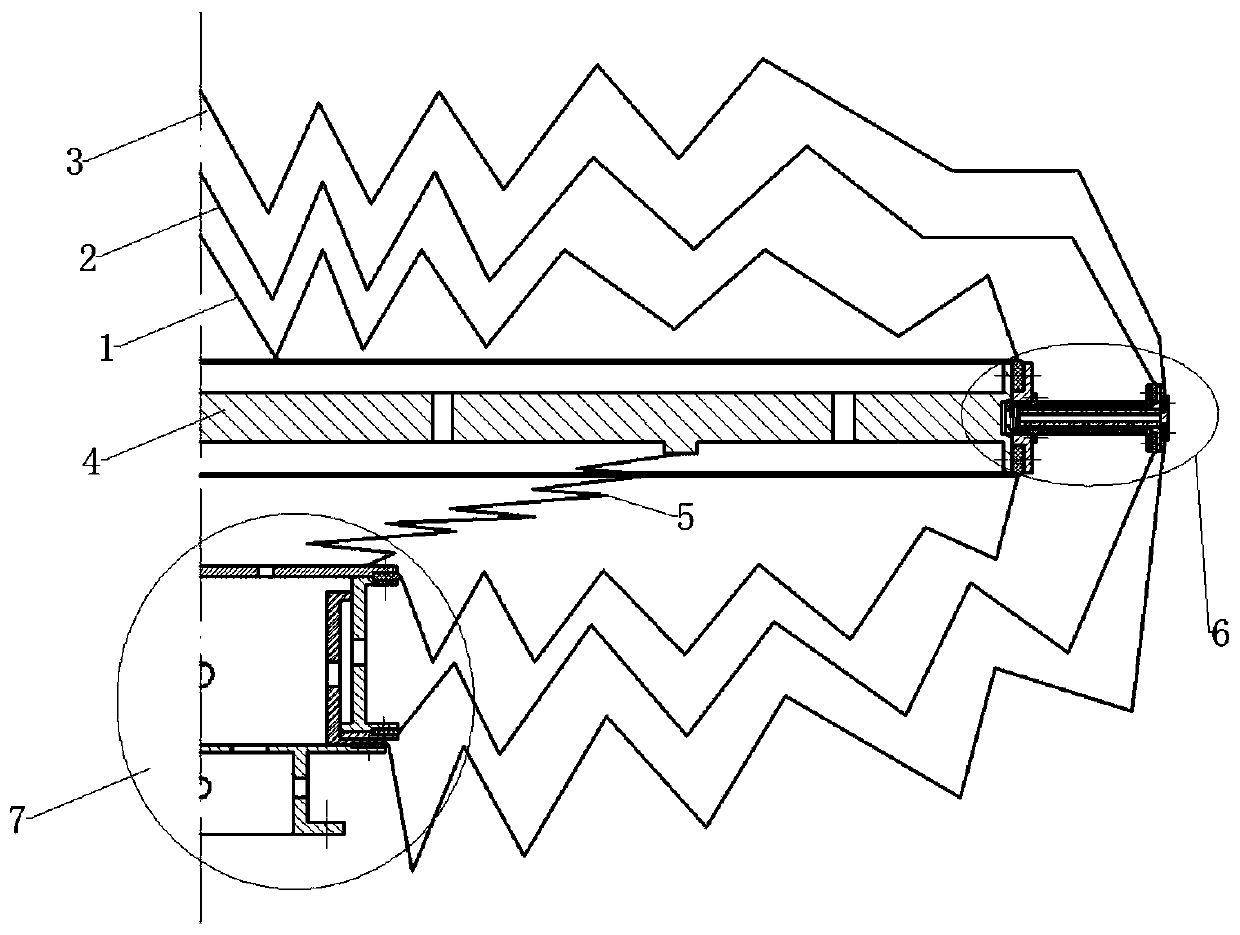

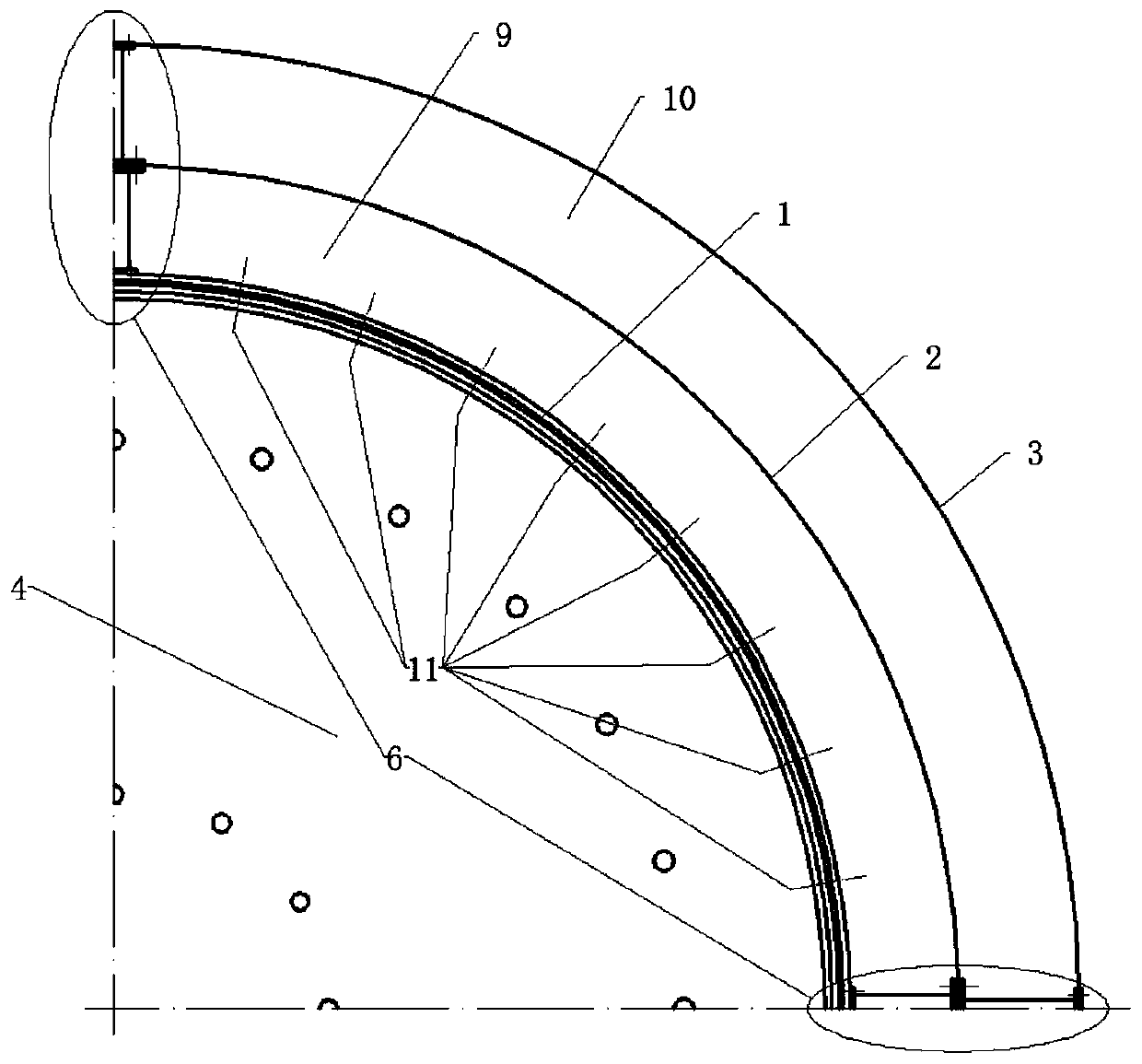

[0027] The laminated film cover 1, 2, 3 behaves as a thin-walled spherical shell after unfolding, and the laminated film cover 1 is made into a flange connection block 12 at the end joint, and the flange connection block 12 is connected with the organic plastic film part of the laminated film cover 1 The material is the same, and it is integrated with the laminated film cover 1. The flange edge of the aluminum honeycomb panel 4, the flange connection block 12 and the inner flange cover 13 form a sandwich flange connection, which is tightened by flange connection bolts 11 that run through the three parts. The flange connection bolts 11 are evenly arranged along the circumference of the aluminum honeycomb panel 4, and the number, material and size of the bolts are selected according to the requirements to ensure the airtightness of the sandwich flange connection.

[0028] Similarly, the laminated film covers 2 and 3 are respectively connected to the flanges of the telescopic rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com