A pipe fitting feeding transfer mechanism

A technology for pipe fittings and feeding, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of difficult adjustment of pipe fitting transmission stations, difficulty in meeting large-scale pipe fitting production and processing, and pipe falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]In order to further describe the present invention, a specific embodiment of a tube sheet transport mechanism is further illustrated in connection with the accompanying drawings, and the present invention is not limited to the following examples.

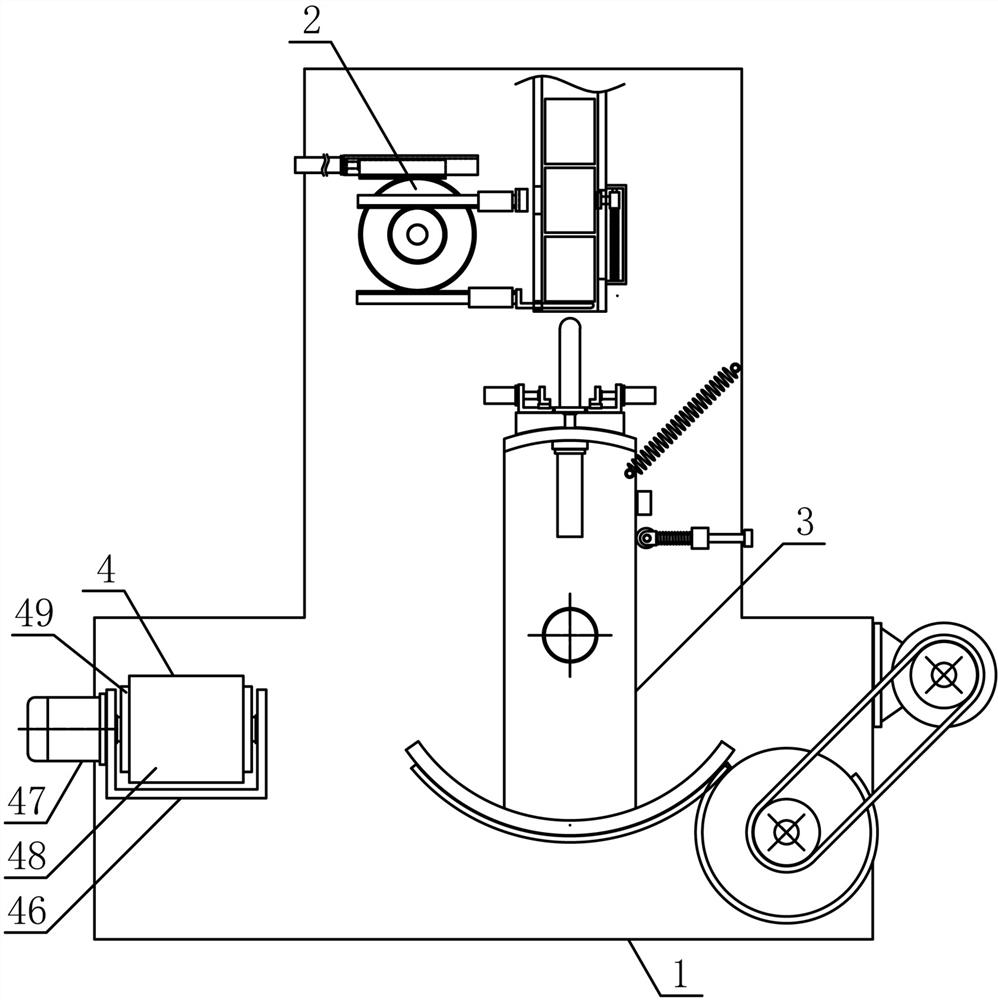

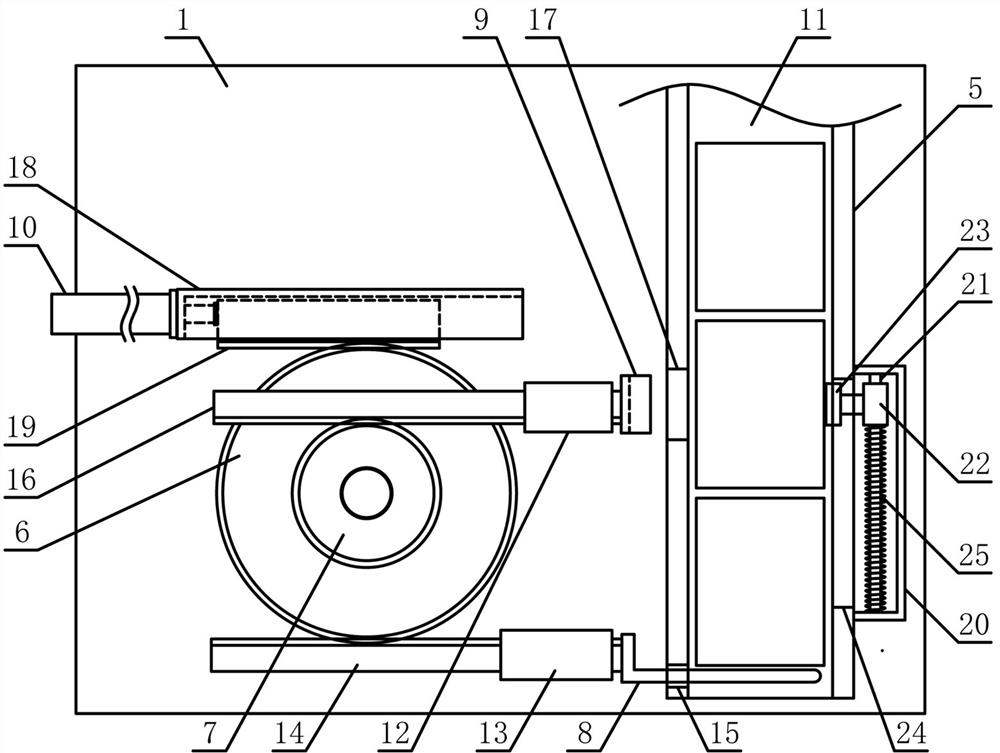

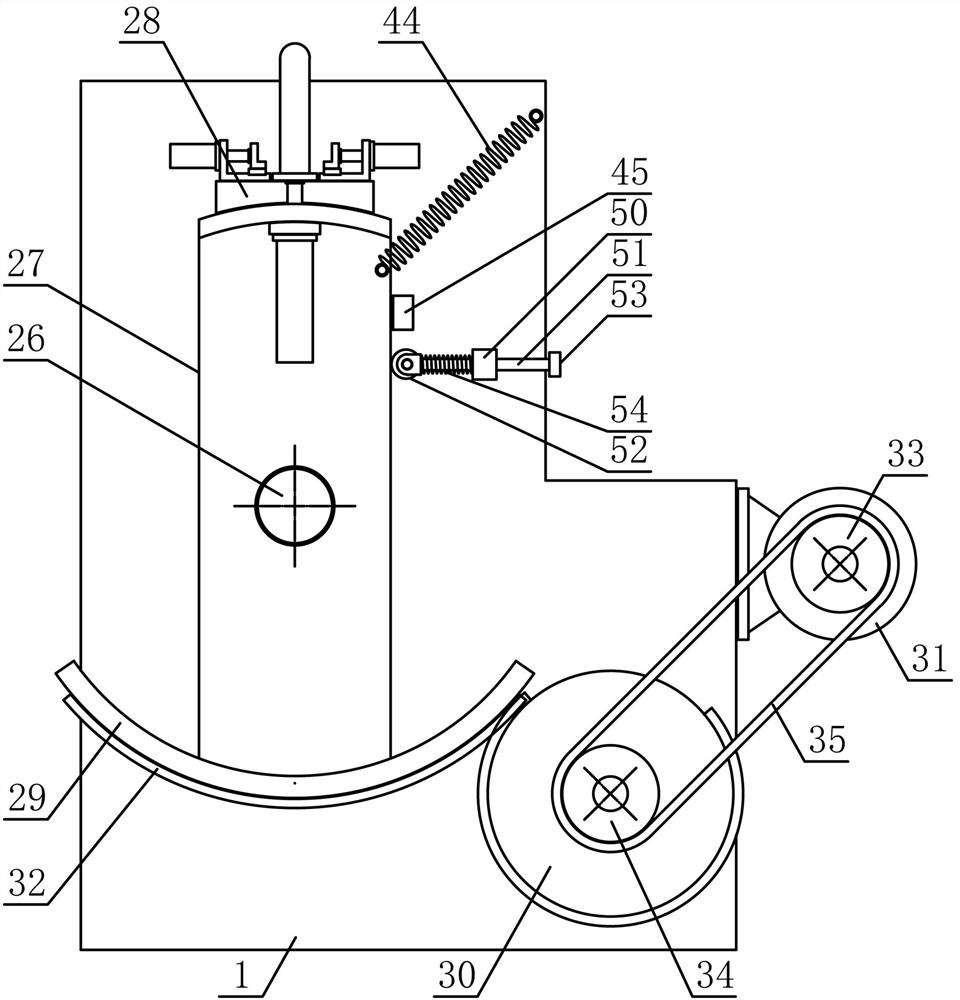

[0016]Such asfigure 1 As shown, the present invention includes a tubular sheet transport mechanism including a top base 1, a catheter mechanism 2, a transport mechanism 3, and a feed mechanism 4, a catheter mechanism 2, and a transport mechanism 3 to securely securely set from the upward direction from top to bottom. On the side of the upper base 1, the feed mechanism 4 is horizontally disposed on the upper base 1 on the side of the transport mechanism 3. Such asfigure 2 As shown, the catheter mechanism 2 of the present invention includes a conduit tube 5, a tube gear 6, a compression gear 7, a tube plate 8, a translational block 9, and a lower cylinder 10, and the conduit tube 5 is vertically disposed on the upper On the upper side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com