Carbon fiber cement base and manufacturing method thereof and winter indoor heating device

A production method and carbon fiber technology, applied in the application field of electric heating performance, can solve the problems of a large amount of manpower and material resources, a large amount of fossil fuels, environmental pollution, etc., and achieve the effect of small environmental impact, less auxiliary equipment, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

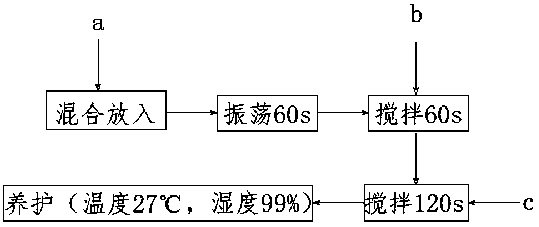

Method used

Image

Examples

Embodiment 1

[0047] A carbon fiber cement base, including cement, water, carbon fiber, silicon powder, dispersant, and defoamer; the proportion by mass is: 1200 parts of cement, 652.5 parts of water, 20.85 parts of carbon fiber, 227.5 parts of silicon powder, and 8~ 4 parts, defoamer 4 parts.

[0048] Preferred: the cement is Portland cement with a strength grade of 42.5; SiO in silica fume 2 The content is 99%; the length of carbon fiber is 7mm, and the resistivity of carbon fiber is 10 7 Ω•mm 2 / m.

Embodiment 2

[0050] A carbon fiber cement base, including cement, water, carbon fiber, silicon powder, dispersant, and defoamer; the proportion by mass is: 1305 parts of cement, 600 parts of water, 16.83 parts of carbon fiber, 197.5 parts of silicon powder, and 11 parts of dispersant , 6 parts of defoamer.

[0051] Preferred: the cement is Portland cement with a strength grade of 46; SiO in silica fume 2 The content is 99%; the length of carbon fiber is 4, and the resistivity of carbon fiber is 10 7 Ω•mm 2 / m.

Embodiment 3

[0053] A carbon fiber cement base, including cement, water, carbon fiber, silicon powder, dispersant, and defoamer; the proportion by mass is: 1250 parts of cement, 625 parts of water, 18.5 parts of carbon fiber, 210.5 parts of silicon powder, and 9 parts of dispersant , 5 parts of defoamer.

[0054] Preferred: the cement is Portland cement with a strength grade of 45; SiO in silica fume 2 The content is 98%; the length of carbon fiber is 6mm, and the resistivity of carbon fiber is 10 7 Ω•mm 2 / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com