Preparation method of high-temperature-resistant reinforced PC composite material

A composite material and high-temperature-resistant technology, which is applied in the field of preparation of high-temperature-resistant reinforced PC composite materials, can solve the problems of not being too popular, high development costs, and high costs, and achieve improved strength and dimensional stability, high cost performance, and improved stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

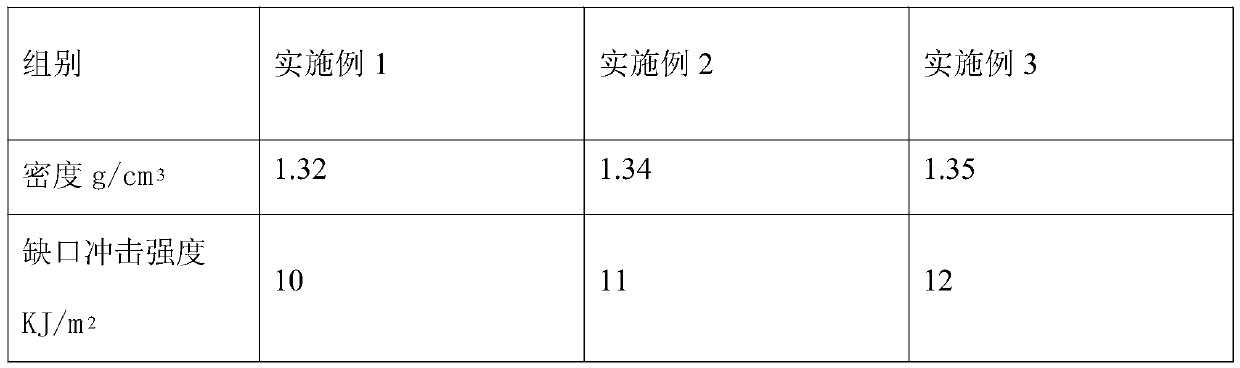

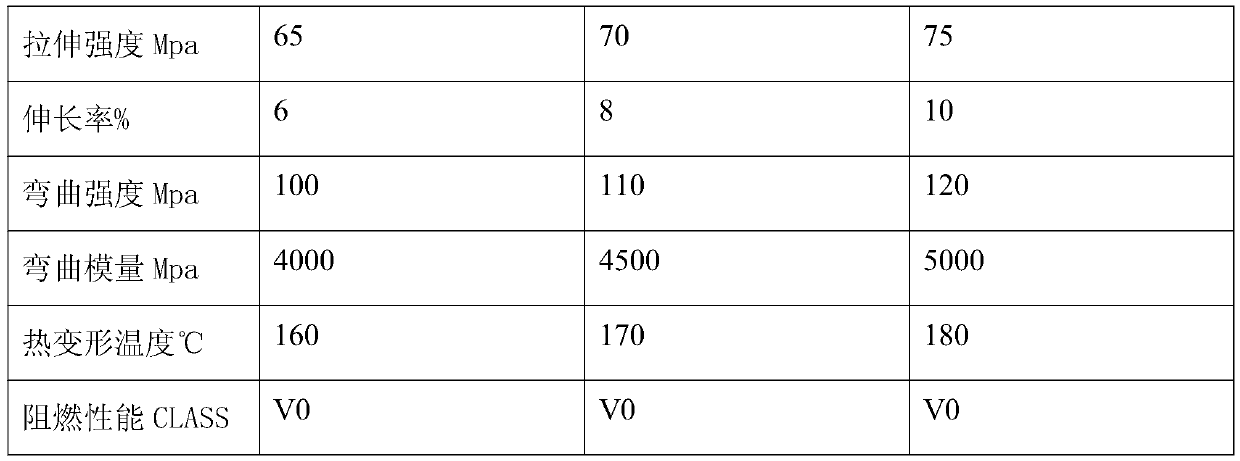

Embodiment 1

[0026] A kind of preparation method of high temperature resistant reinforced PC composite material of the present embodiment, comprises the following steps:

[0027] Step 1, weigh the following raw materials according to weight percentage: 51% of PC substrate, 10% of polyetherimide, 4% of compatibilizer, 1% of toughening agent, 3% of chopped glass fiber, 13% of long glass fiber, Antioxidant 0.3%, lubricant 0.3%, flame retardant 0.4%, anti-dripping agent 0.2%; diffusing oil 0.01%;

[0028] Step 2: Add PC base material and polyetherimide into the mixer, then add diffusion oil, start the mixer and increase the stirring speed to 50r / min, stir for 5 minutes, until the diffusion oil is fully mixed in the PC base material Uniform;

[0029] Step 3, then put the compatibilizer, toughening agent, lubricant, flame retardant, antioxidant and anti-dripping agent into the mixer in step 2, and continue to stir at a speed of 50r / min for 10min;

[0030] Step 4, put the chopped glass fiber in...

Embodiment 2

[0041] A kind of preparation method of high temperature resistant reinforced PC composite material of the present embodiment, comprises the following steps:

[0042] Step 1, weigh the following raw materials according to weight percentage: 66% of PC substrate, 15% of polyetherimide, 6% of compatibilizer, 2% of toughening agent, 7% of chopped glass fiber, 17% of long glass fiber, Antioxidant 0.5%, lubricant 0.5%, flame retardant 0.8%, anti-dripping agent 0.4%; diffusing oil 0.03%;

[0043] Step 2: Add PC substrate and polyetherimide into the mixer, then add diffusion oil, start the mixer and increase the stirring speed to 50r / min, stir for 5-8min, until the diffusion oil is in the PC substrate Mix well;

[0044] Step 3, then put the compatibilizer, toughening agent, lubricant, flame retardant, antioxidant and anti-dripping agent into the mixer in step 2, and continue to stir at a speed of 50r / min for 15min;

[0045] Step 4, put the chopped glass fiber into the mixer in Step 3...

Embodiment 3

[0056] A kind of preparation method of high temperature resistant reinforced PC composite material of the present embodiment, comprises the following steps:

[0057] Step 1, weigh the following raw materials according to weight percentage: 58% of PC substrate, 12.5% of polyetherimide, 5% of compatibilizer, 1.5% of toughening agent, 5% of chopped glass fiber, 15% of long glass fiber, Antioxidant 0.4%, lubricant 0.4%, flame retardant 0.6%, anti-dripping agent 0.3%; diffusing oil 0.02%;

[0058] Step 2: Add the PC substrate and polyetherimide into the mixer, then add the diffusion oil, start the mixer and increase the stirring speed to 50r / min, and stir for 6.5min until the diffusion oil is fully dispersed in the PC substrate well mixed;

[0059] Step 3, then put the compatibilizer, toughening agent, lubricant, flame retardant, antioxidant and anti-dripping agent into the mixer in step 2, and continue to stir at a speed of 50r / min for 12.5min;

[0060] Step 4, put the chopped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com