Compound sealing method for kerf in soft contact electromagnetic continuous casting crystallizer

A continuous casting crystallizer and composite sealing technology, applied in the direction of pressure inorganic powder coating, coating, metal material coating technology, etc., to achieve the effect of safe and reliable cooling water circuit, good sealing performance, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

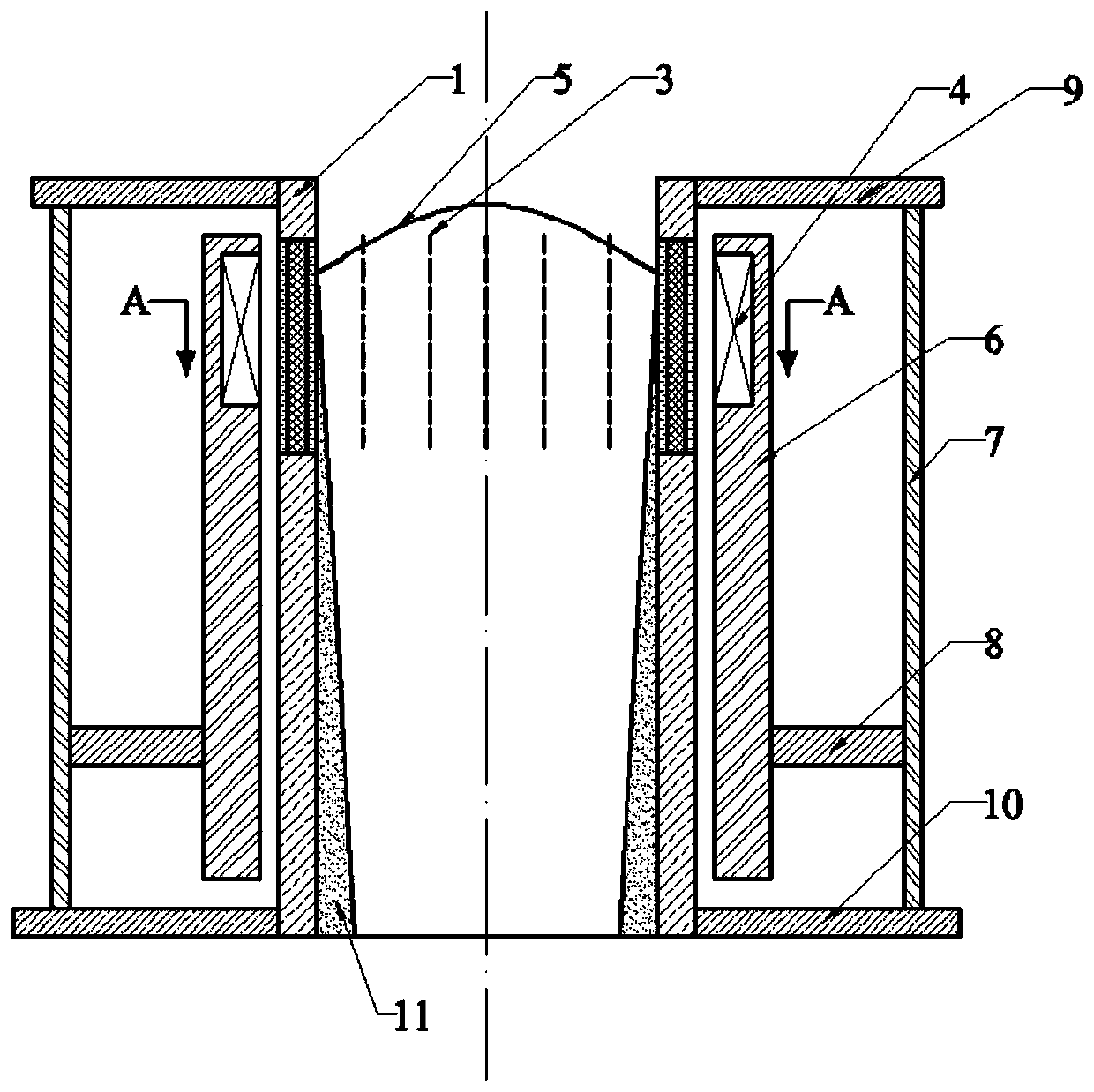

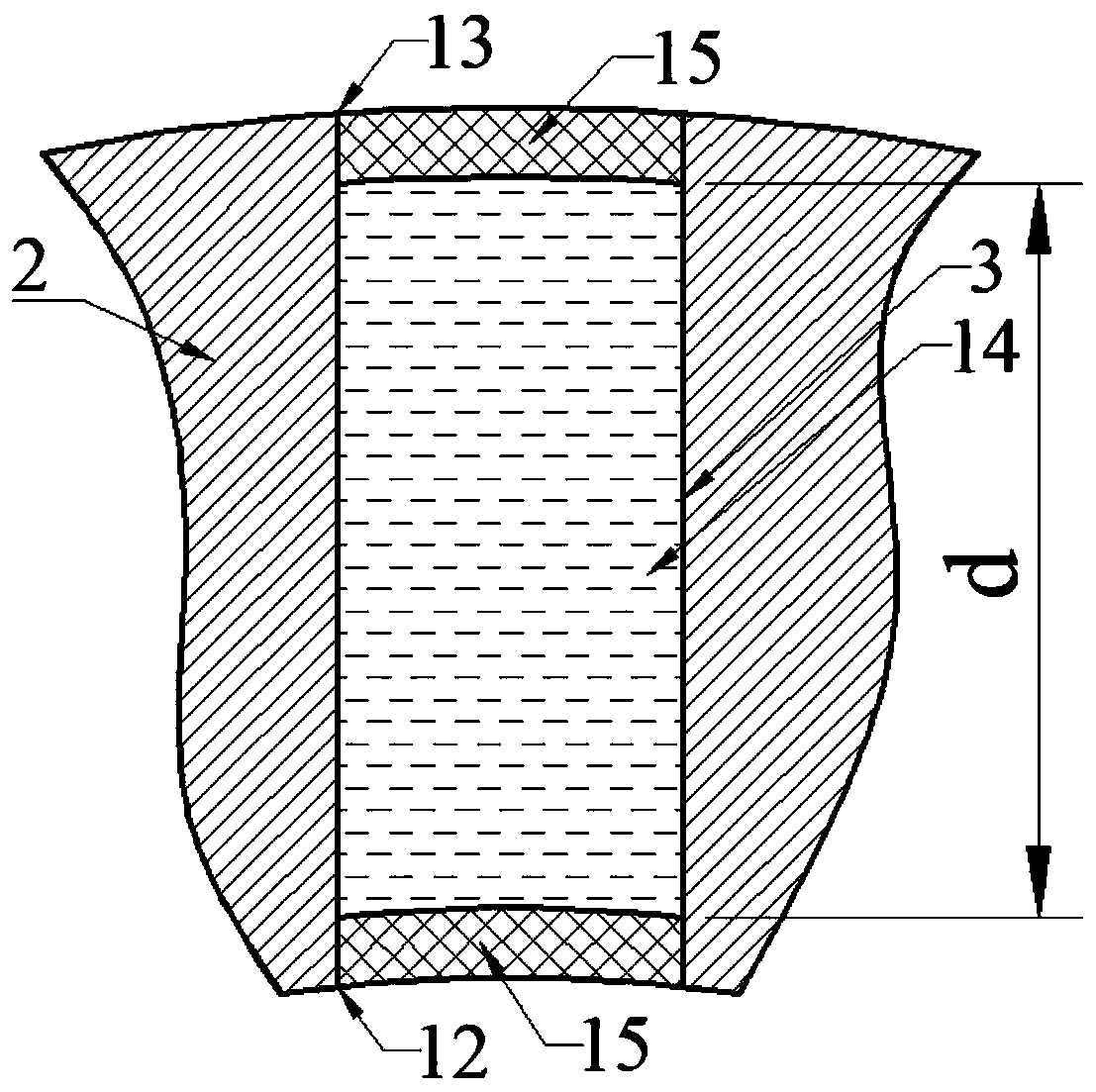

[0026] In this example, see Figure 1-3 , a soft-contact electromagnetic continuous casting mold slit compound sealing method, in which a hollow slit 3 is made on the mold wall 1, and then the slit 3 is cleaned and pretreated, and the hollowed slit 3 runs through the mold The inner and outer surfaces of the wall 1; filling material 14 is added in the middle of the slit 3, and the filling material 14 is a poor conductor of electricity, so that the filling material 14 fills the middle part of the slit 3, and the surface of the filling material 14 does not reach the slit 3 The surface of the crystallizer wall 1 in the direction of the opening forms a shallow groove; then continue to add sealing material 15 to the shallow groove until the shallow groove is filled, and the sealing material 15 adopts a material that can be firmly combined with the crystallizer matrix material; thereby making the surface of the sealing material 15 It is flush with the surface of the mold copper tube ...

Embodiment 2

[0030] The present embodiment is basically the same as the embodiment, and it is pointed out in particular that:

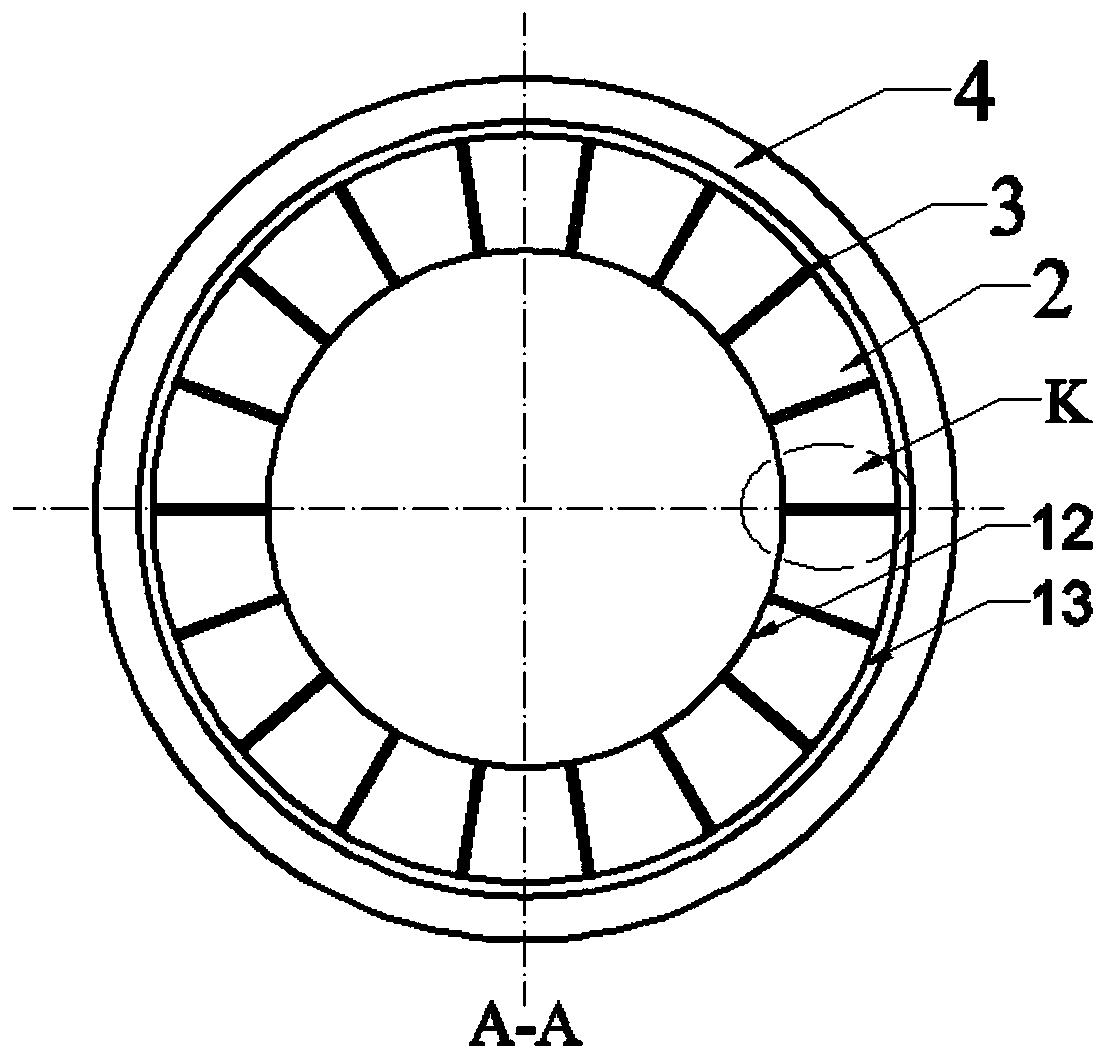

[0031] In the present embodiment, select the circular copper tube of pure copper crystallizer for use, and the diameter of the copper tube is 180mm, and the slit is started at 30mm below the top surface of the copper tube of the crystallizer; the slit 3 has a width of 1mm and a length of 150mm. There are 30 equidistant slits 3 in the circumferential direction, and the wall thickness of the copper pipe is 40mm. Firstly, the slits 3 are cleaned and sandblasted, and the thermal spraying method is used for thermal spraying, and then the middle part of the slit is sprayed and preheated to 1000°C ZrO 2 powder to make ZrO 2 The powder fills the middle part of the slit 3, the filling thickness d is 38mm, and the ZrO 2 The surface of the powder filling material does not reach the surface of the crystallizer wall in the direction of the opening of the slit, forming a shal...

Embodiment 3

[0034] This embodiment is basically the same as the previous embodiment, and it is particularly pointed out that:

[0035] In this example, see Figure 4 , a soft-contact electromagnetic continuous casting mold slit composite sealing method, making a non-hollow slit 3 on the mold wall 1, and the non-hollow slit 3 is a deep slit open toward the outer surface of the mold wall 1 Groove 16; then clean and pre-treat the slit 3, the hollow slit 3 runs through the inner and outer surfaces of the crystallizer wall 1; add a filling material 14 in the middle of the slit 3, and the filling material 14 is a poor conductor of electricity , make the filling material 14 fill up the middle part of the slit 3, and make the surface of the filling material 14 less than the surface of the crystallizer wall 1 in the opening direction of the slit 3, forming a shallow groove; then continue to add the sealing material 15 to the shallow groove until it is filled The shallow groove is full, and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com