Preparation process of low-elastic composite yarns of moisture-absorption and sweet-releasing dacron

A polyester low-elasticity, moisture-absorbing and sweat-wicking technology, which is applied in filament/thread forming, textile and papermaking, fiber treatment, etc., can solve the problem that the fabric feel, appearance, texture, luster and elasticity cannot meet high requirements and product quality cannot meet Requirements, grades cannot meet the requirements, etc., to achieve the effect of plump hand feeling, good moisture absorption and perspiration effect, and significant soft luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation process for moisture-absorbing and sweat-wicking polyester low-elastic composite yarn, comprising the following steps:

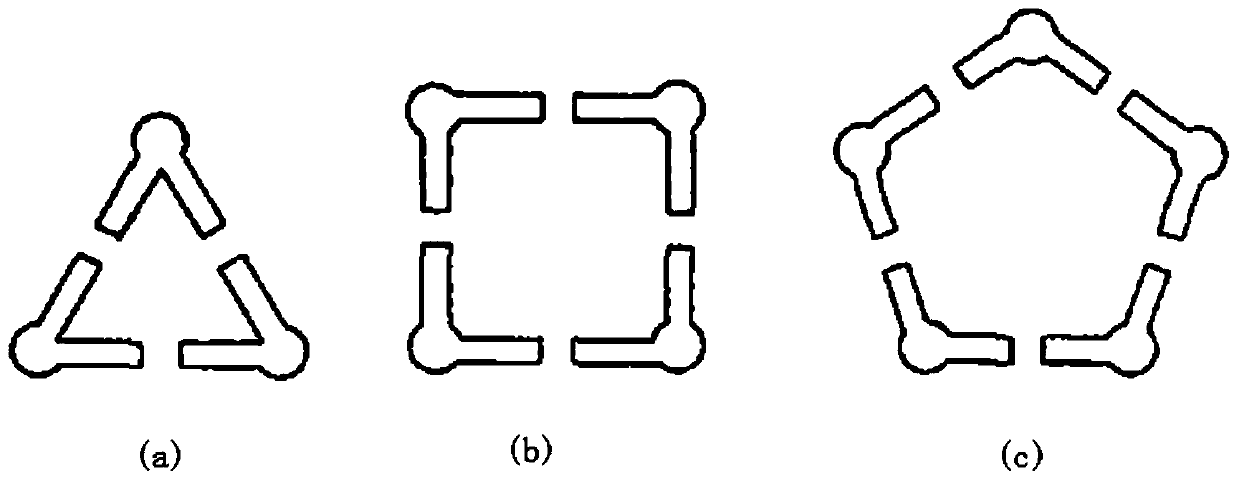

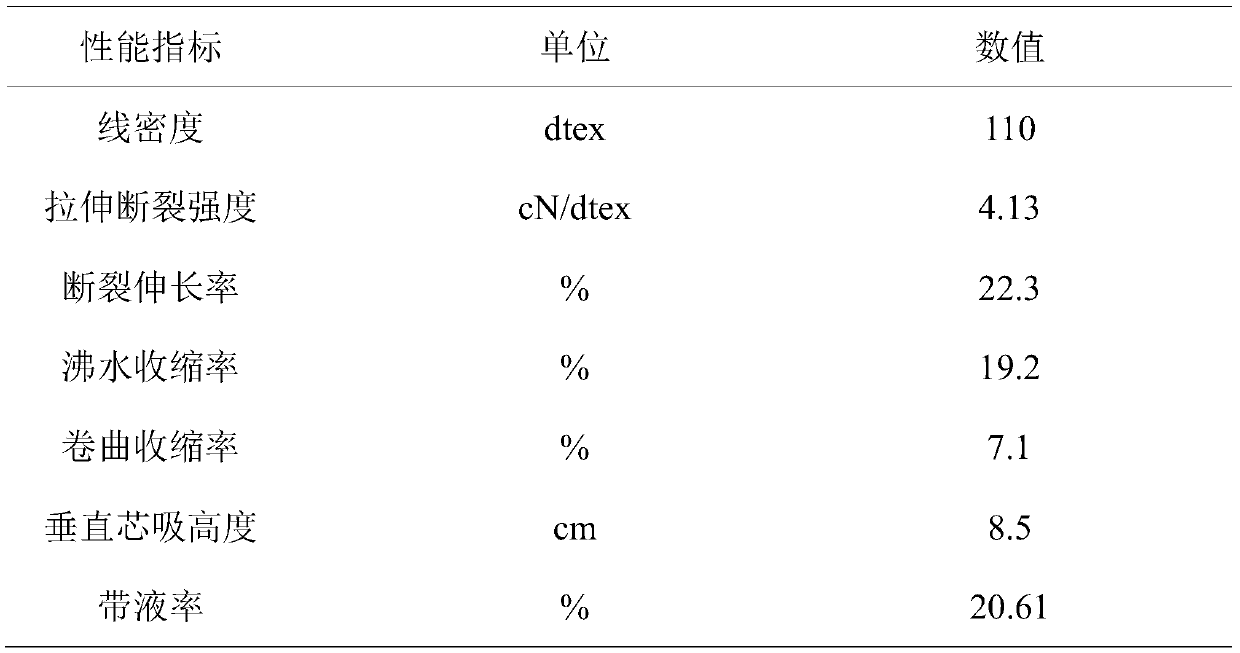

[0023] (1) Preparation of special-shaped POY raw yarn: pass the polyester chip through the wet chip silo and enter the pre-crystallization stage. The temperature of the pre-crystallization is 170°C, and the pre-crystallization time is 14 minutes. After the pre-crystallization, it is homogenized and dried. The drying temperature is 182°C, and the drying time is 5 hours to obtain PET dry chips, which enter the screw extruder. The screw extruder is divided into 6 zones, and the screw temperature is 260-285°C. body, and filter the melt impurities, the melt enters the spinning assembly for melt spinning, the spinning temperature is 285°C, and the fine flow of the melt ejected from the spinning assembly is solidified and cooled by the airflow blown out by the side blowing cooling device to form filaments , wherein, the side blowing temperature...

Embodiment 2

[0027] A preparation process for moisture-absorbing and sweat-wicking polyester low-elastic composite yarn, comprising the following steps:

[0028] (1) Preparation of special-shaped POY raw yarn: pass the polyester chip through the wet chip silo and enter the pre-crystallization stage. The temperature of the pre-crystallization is 173°C, and the pre-crystallization time is 12 minutes. After the pre-crystallization, it is homogenized and dried. The drying temperature is 180°C and the drying time is 6 hours to obtain PET dry chips, which enter the screw extruder. The screw extruder is divided into 6 zones, and the screw temperature is 260-285°C. body, and filter the melt impurities, the melt enters the spinning assembly for melt spinning, the spinning temperature is 285°C, and the fine flow of the melt ejected from the spinning assembly is solidified and cooled by the airflow blown out by the side blowing cooling device to form filaments , wherein, the side blowing temperature ...

Embodiment 3

[0032] A preparation process for moisture-absorbing and sweat-wicking polyester low-elastic composite yarn, comprising the following steps:

[0033] (1) Preparation of special-shaped POY raw yarn: pass the polyester chip through the wet chip silo and enter the pre-crystallization stage. The temperature of the pre-crystallization is 175 ° C, and the pre-crystallization time is 14 minutes. After the pre-crystallization, it is homogenized and dried. The drying temperature is 185°C and the drying time is 4 hours to obtain PET dry chips, which enter the screw extruder. The screw extruder is divided into 6 zones, and the screw temperature is 260-285°C. body, and filter the melt impurities, the melt enters the spinning assembly for melt spinning, the spinning temperature is 290°C, the fine flow of the melt ejected from the spinning assembly is solidified and cooled by the airflow blown out by the side blowing cooling device to form filaments , wherein, the side blowing temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com