Novel template-free anti-corrosion UHPC-NC combined bearing platform and construction method thereof

A UHPC-NC, construction method technology, applied in infrastructure engineering, construction, etc., can solve the problems affecting the safety and normal operation of power transmission and transformation lines, tilting towers, poor results, etc., to improve anti-corrosion ability and reduce on-site operations. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention, but not to limit the protection scope of the present invention.

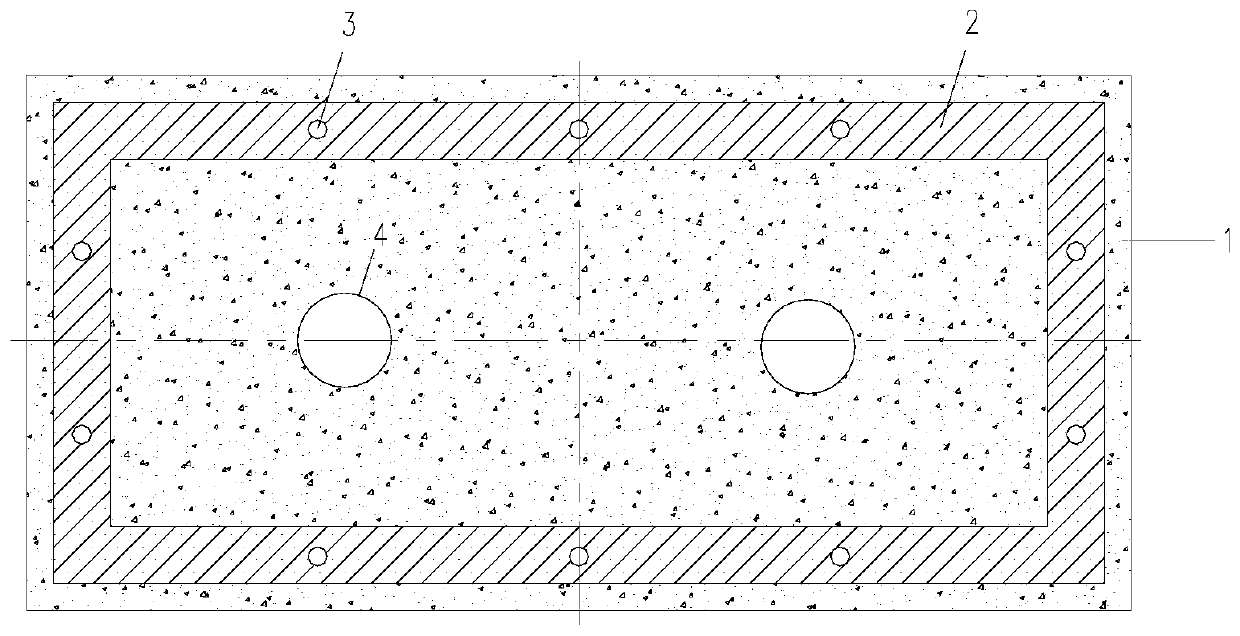

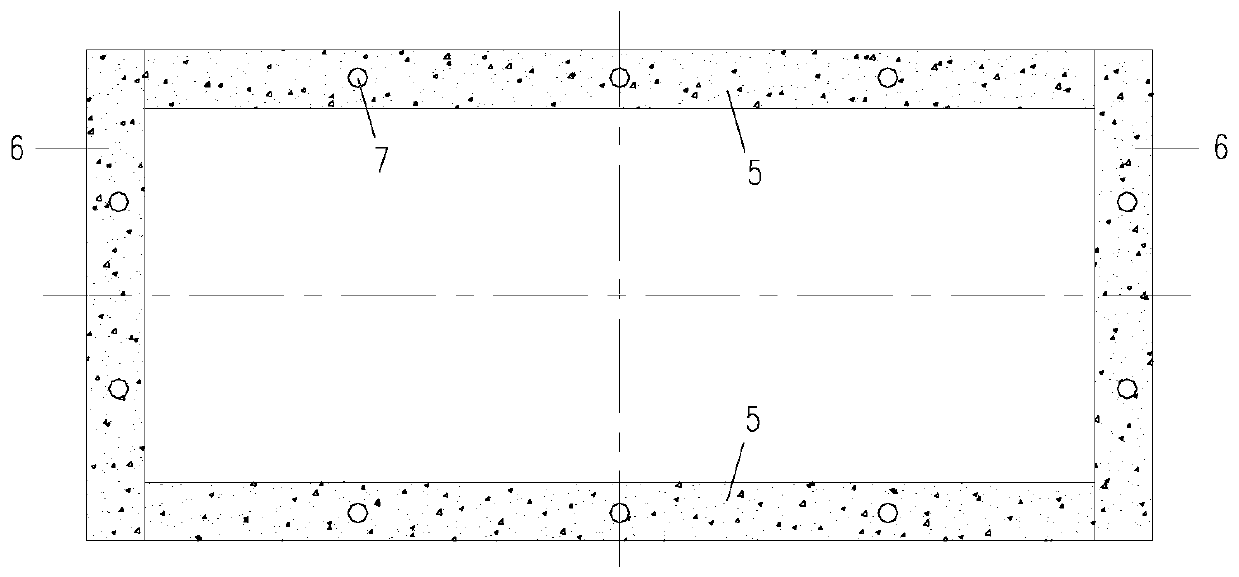

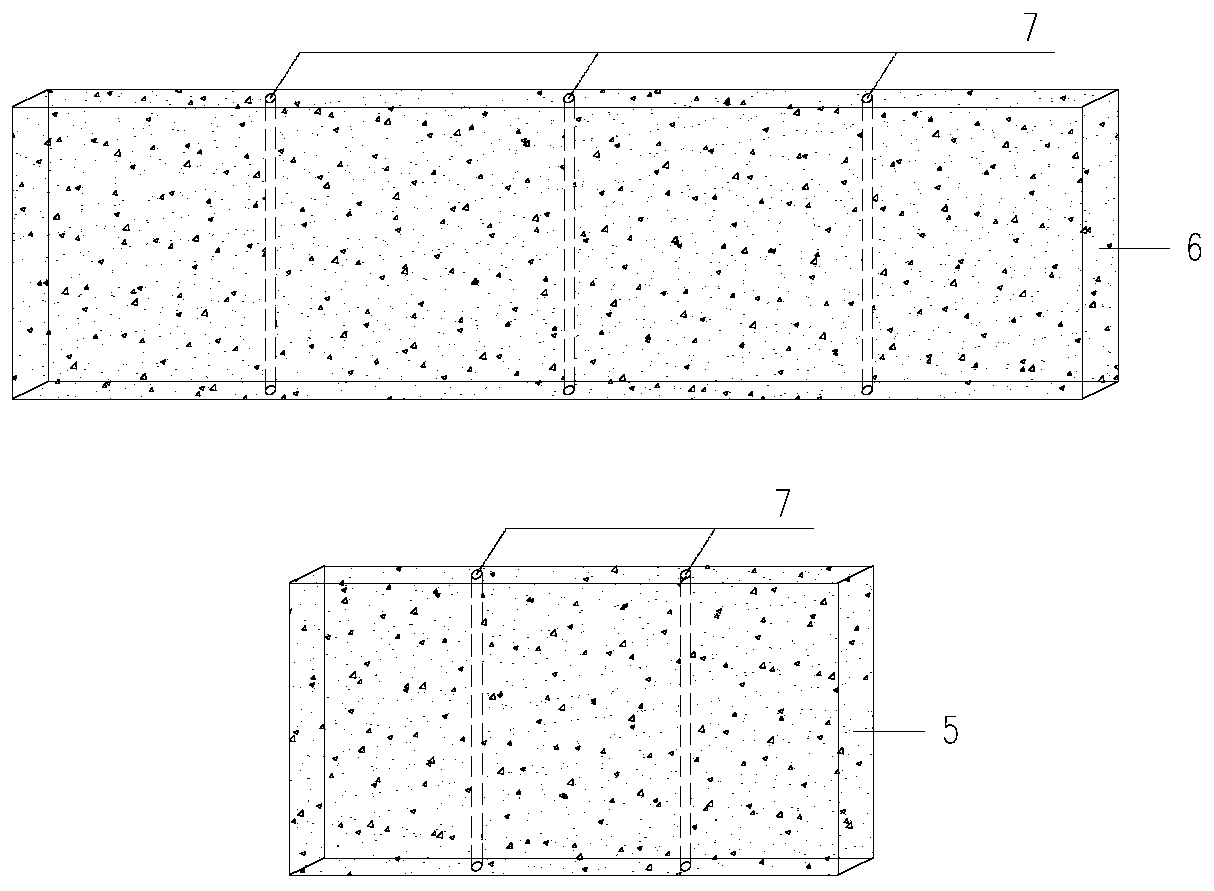

[0024] The invention provides a novel formwork-free anti-corrosion ultra-high performance active powder concrete (UHPC)-common concrete (NC) cap, which is characterized in that: the cap includes a prefabricated UHPC protective layer and a core common concrete part, and the prefabricated UHPC protection The first layer includes the prefabricated UHPC cap bottom plate 1, the bottom plate reserved groove 2, the bottom plate reserved round hole 3, and the bottom plate reserved pile hole 4 (such as figure 1 shown); prefabricated UHPC No. Ⅰ side panel 5 and No. Ⅱ side panel 6, and reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com