Special equipment for collecting flue gas generated by yellow phosphorus

A technology of flue gas collection and special equipment, applied in lighting and heating equipment, phosphorus compounds, waste heat treatment, etc., can solve the rising of white smoke, reduce the cleanliness of the slag working environment, and cannot clearly observe the slag quenching process and results, etc. To improve the comprehensiveness of emissions, avoid residual accumulation, and improve cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

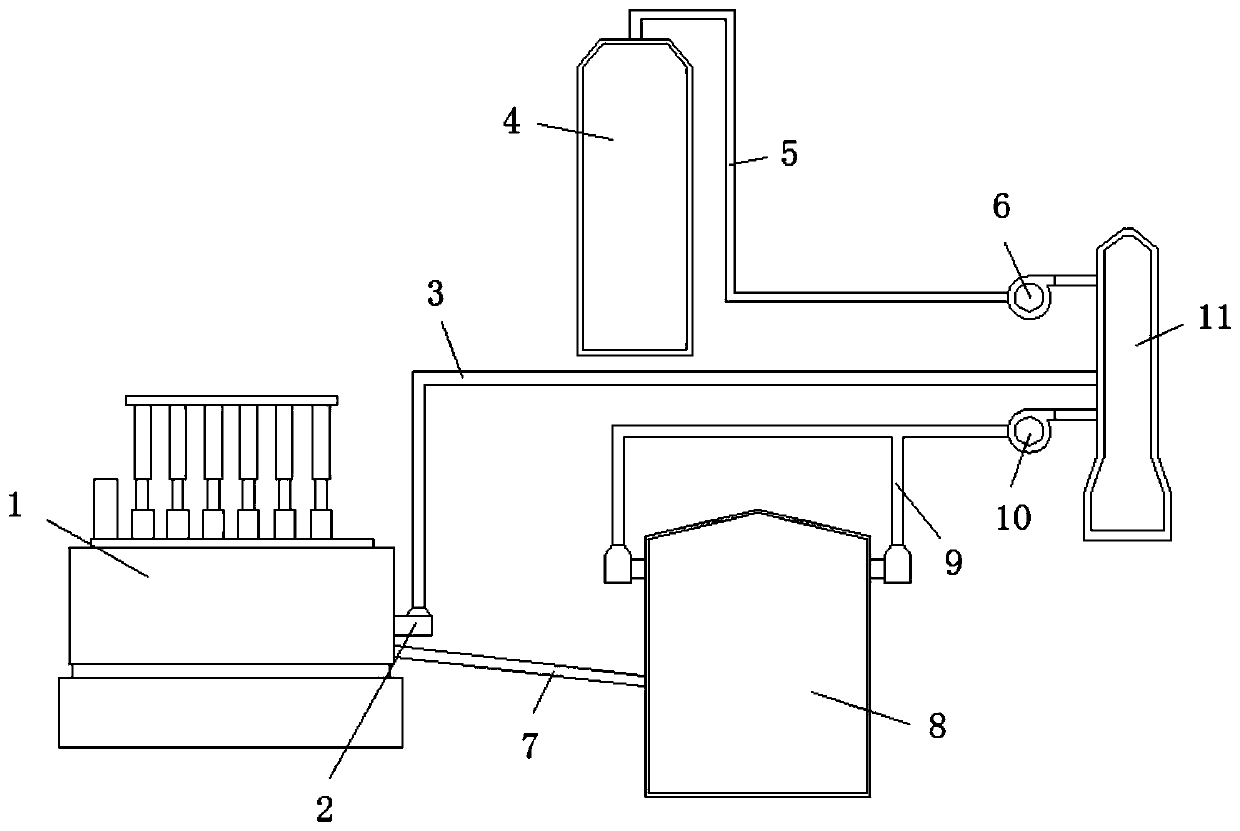

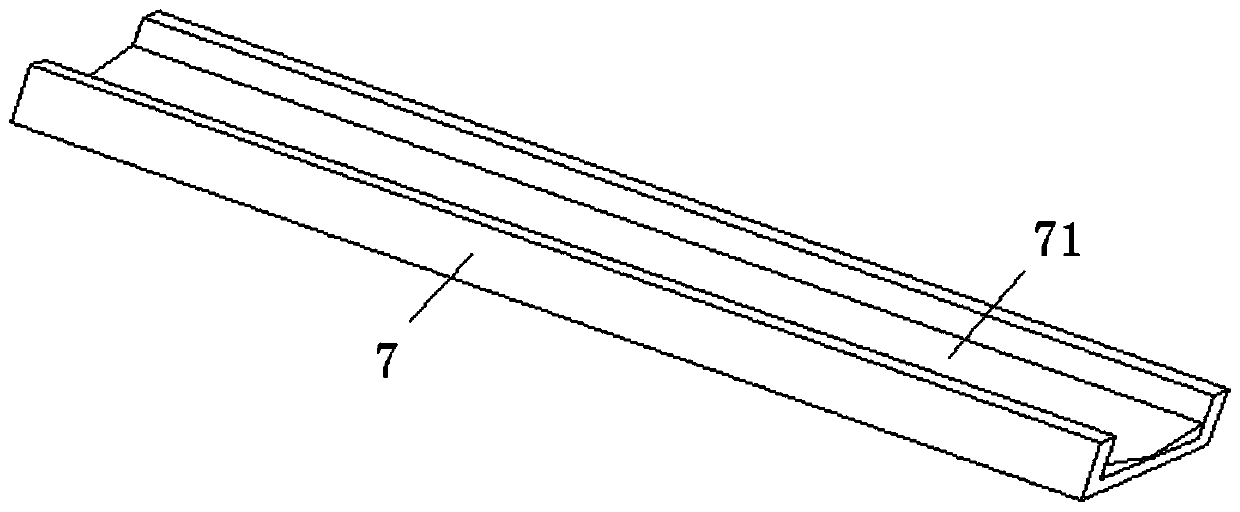

[0045] like figure 1 Shown, a kind of special equipment for yellow phosphorus production flue gas collection comprises: electric furnace 1, washing tower 4, slag pool 8 and discharge chimney 11;

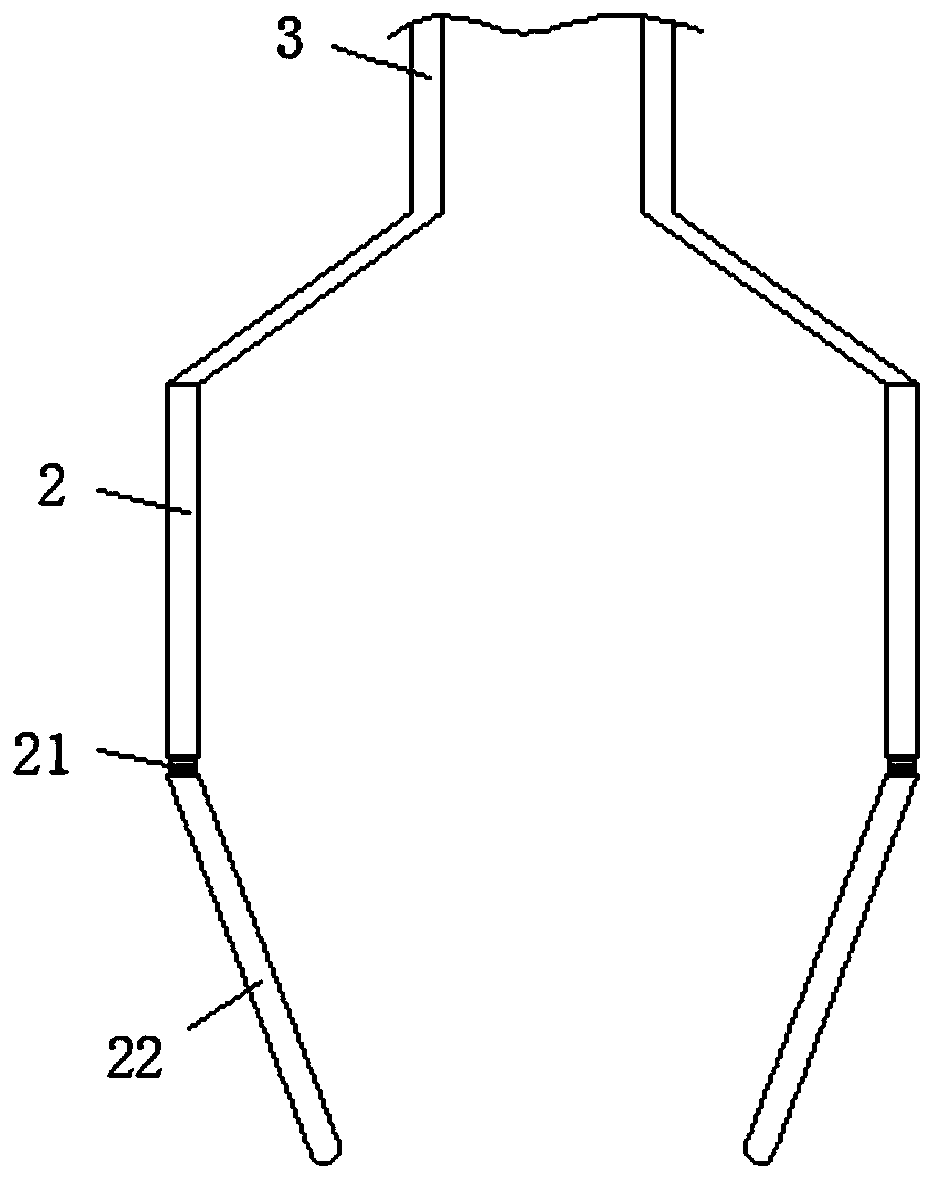

[0046] The outer wall of the electric furnace 1 is provided with a slag outlet exhaust hood 2, and the slag outlet exhaust hood 2 communicates with the exhaust chimney 11 through the slag outlet flue gas pipe 3;

[0047] The washing tower 4 communicates with the discharge chimney 11 through the refined tail gas flue gas pipe 5;

[0048] The slag pool 8 communicates with the discharge chimney 11 through the slag quenching steam flue gas pipe 9 .

[0049] Working principle:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com