Plain weave fabric extensibility presetting method and plain weave fabric manufacturing method for setting extensibility

A plain weave fabric and elongation technology, which is applied in the field of fabric weaving, can solve the problems that the elongation and elongation of woven fabrics are not easy to predict and determine, and the wear resistance, washing resistance and durability of knitted fabrics are not as good as those of woven fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

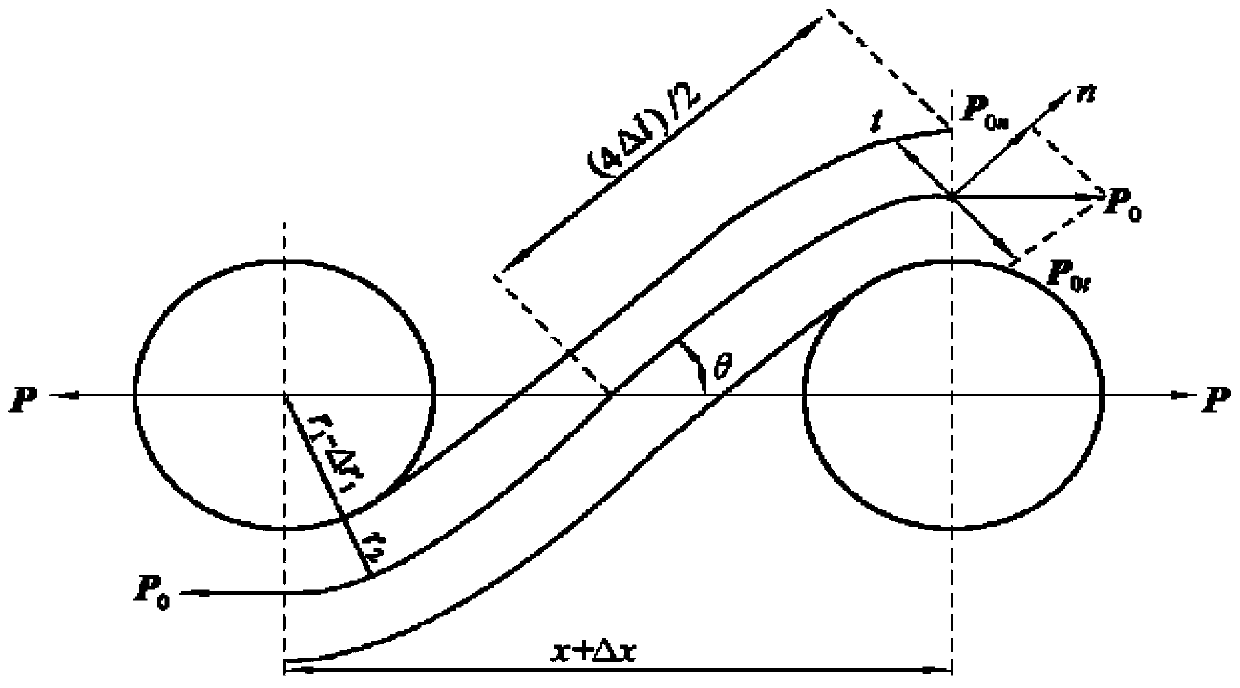

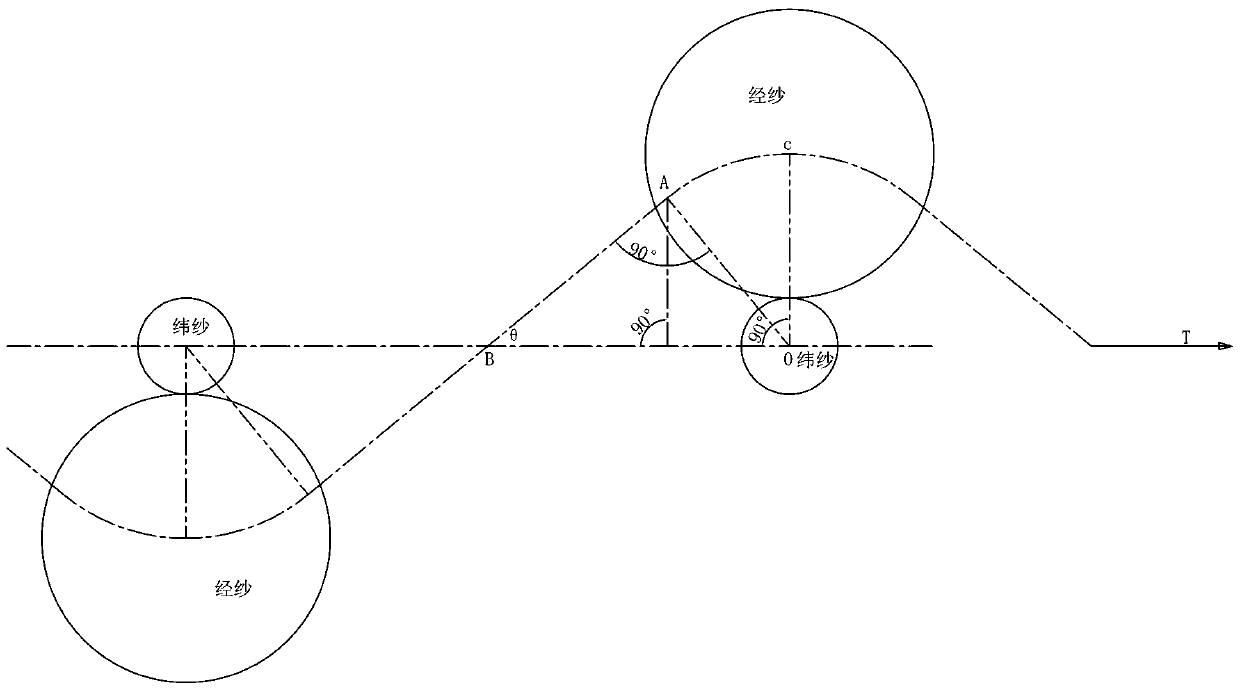

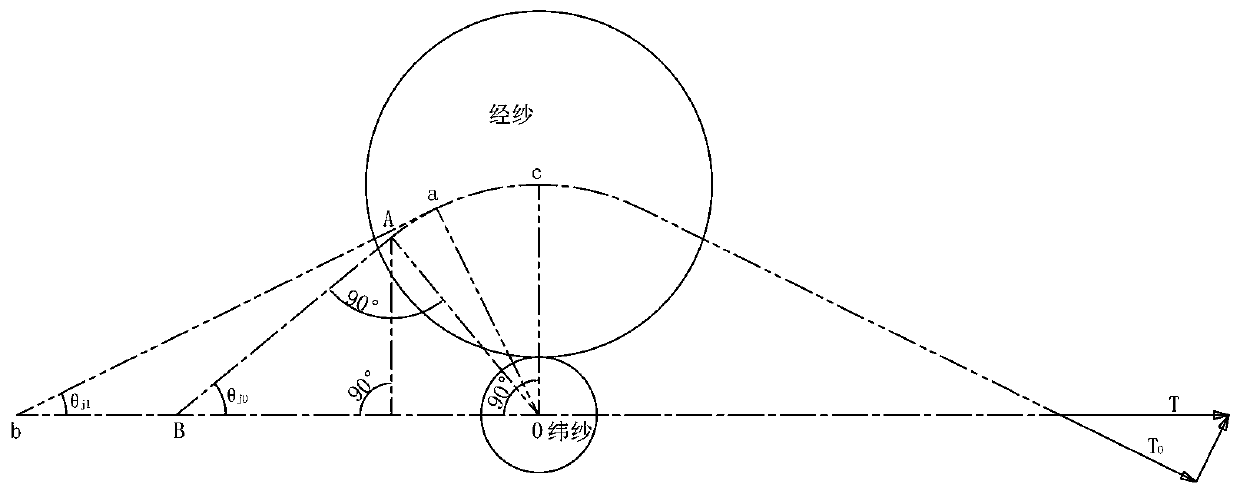

[0075] Embodiment 1: a kind of radial extensibility measuring method of plain weave fabric, comprises the steps:

[0076] Get the warp radius r of the fabric to be made j , weft radius r w ; The specific method is to measure the warp yarn density N of the fabric to be tested tj , weft yarn density N tw (unit tex), and the warp volume weight coefficient δ in the standard state j and weft volume weight coefficient δ w (unit mg / mm 3 ), then the warp radius

[0077]

[0078] Weft radius

[0079]

[0080] Take the fabric sample to be tested and measure the warp length X of the fabric to be made j and weft length X w (unit cm), obtain the number of warp yarns P in the 1cm weft length of the fabric to be made j , the number of weft yarns P in the warp length of 1cm w (unit root / cm); the specific method is to take a 5cm × 5cm standard sample of the fabric to be tested. At this time, the warp length X j 5cm, weft length X w is 5cm; check the number of warp yarns in th...

Embodiment 2

[0087] Embodiment 2: a kind of weft extensibility measuring method of plain weave fabric, principle is the same as the weft direction extensibility measuring method of plain weave fabric in embodiment 1, comprises the steps:

[0088] Get the warp radius r of the fabric to be made j , weft radius r w ;

[0089] Take the fabric sample to be tested and measure the warp length X of the fabric to be made j and weft length X w (unit cm), obtain the number of warp yarns P in the 1cm weft length of the fabric to be made j , the number of weft yarns P in the warp length of 1cm w (unit root), with the geometric equation

[0090] T w (unit cN), in general, measure the fabric sample to be tested (that is, the warp length is X j and a latitudinal length of X w ) latitudinal breaking strength T wD , in actual operation, it is advisable to choose a standard sample with a fabric warp length of 5cm specified in the standard, then T w =y wD T wD ,y wD ≤30%. as required, y wD One ...

Embodiment 3

[0125] Embodiment 3: a kind of warp extensibility predetermined method of plain weave fabric, comprises the following steps:

[0126] Set the physical quantity step, prefetch the warp radius r of the fabric to be made j , weft radius r w ;Prefetch the number of warp yarns in the unit length of the weft direction of the fabric to be made P j , the number of weft yarns per unit length in the warp direction P w ;Prefetch the warp length X of the fabric to be made j and weft length X w , the warp breaking strength T of the fabric to be produced jD ;

[0127] Set the force coefficient y of the warp jD ,y jD ≤30%;

[0128] Then the warp elongation ΔL of the fabric to be made j can be derived from the following equations:

[0129]

[0130] where r j is the warp radius, r w is the weft radius, T jD is the warp breaking strength of the fabric, P j is the number of warp yarns per unit length in the weft direction of the fabric, P w is the number of weft yarns per unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com