Semiconductor laser light source and laser projector

A laser projector and laser light source technology, applied in the laser field, can solve the problems of affecting the life of the laser system, the method of eliminating speckle is complicated, etc., to achieve the effect of improving the picture quality, improving the viewing experience, and increasing the spectral width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

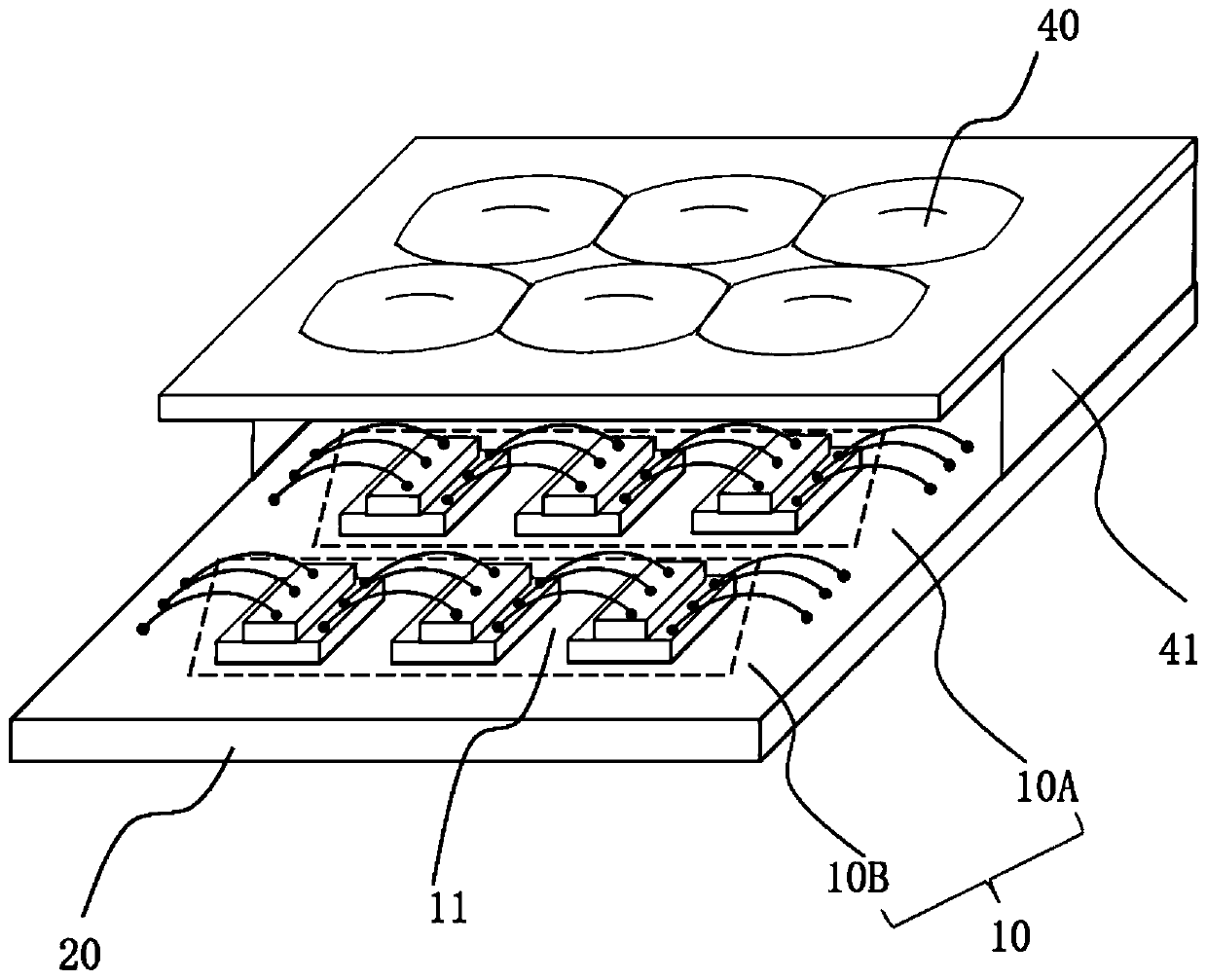

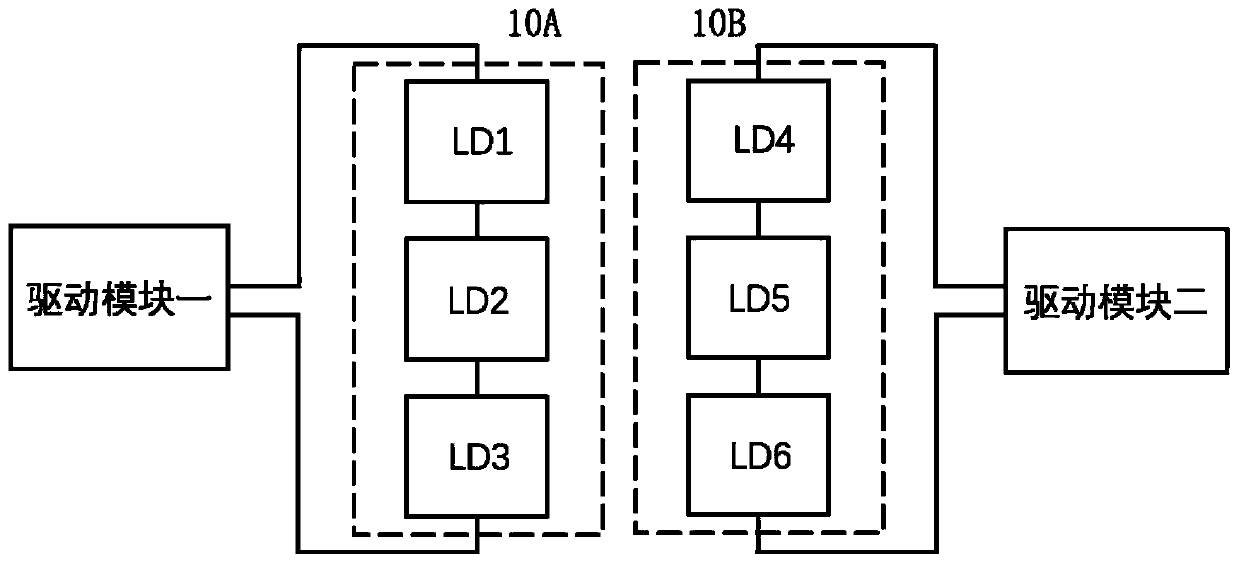

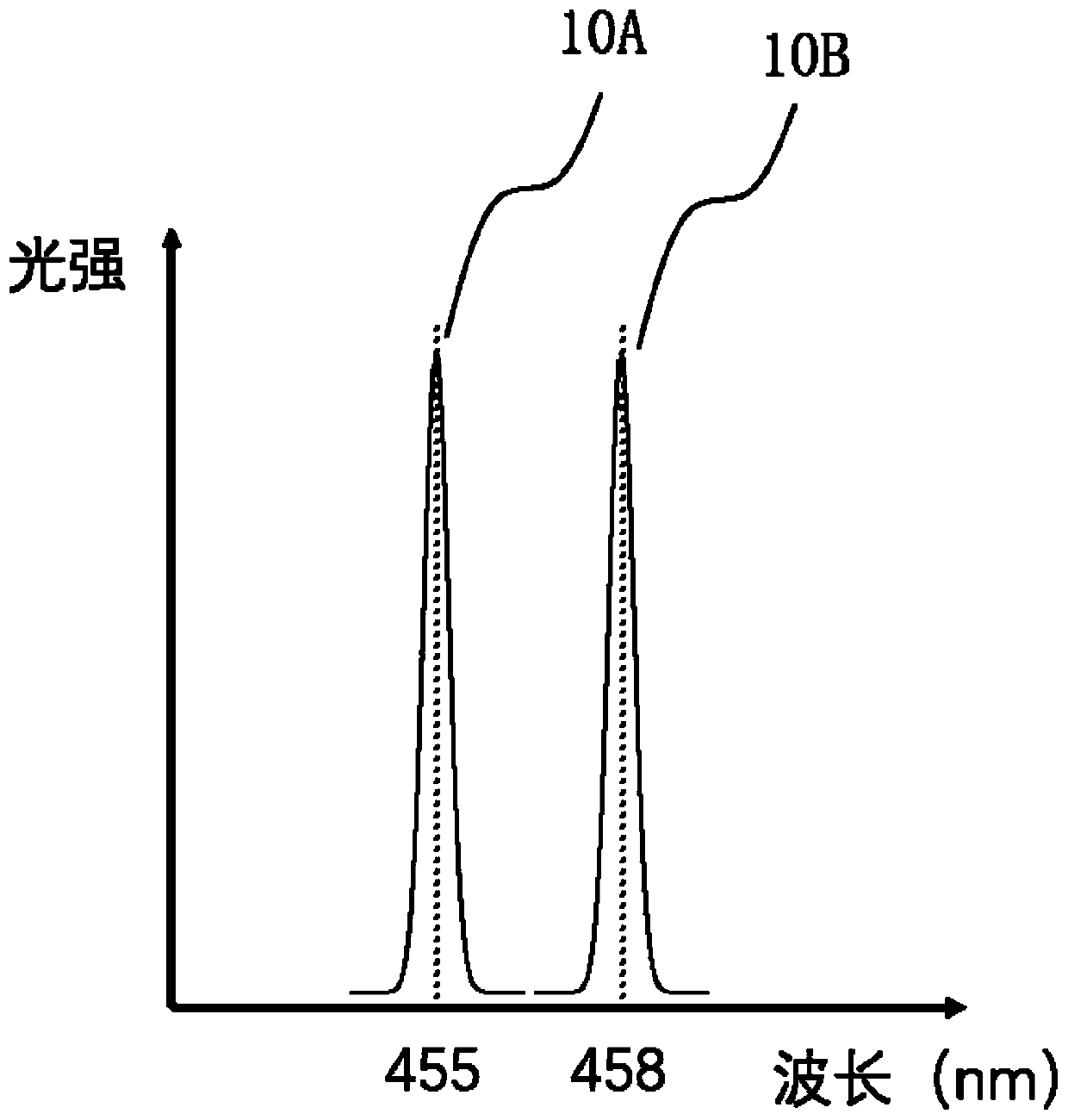

[0032] figure 1 Shown here is a schematic structural diagram of a semiconductor laser light source according to this embodiment, which includes a laser diode array 10, a substrate 20, a driving module 30, and a collimating module 40. The laser diode array 10 contains 6 laser diodes, each of which is divided into a laser diode group, which is distributed in a 2×3 rectangular array on the substrate 20 and is fixedly connected to the substrate 20. To avoid thermal interference between each other, the laser diodes are distributed at equal intervals of 5mm in two mutually perpendicular directions. The first row 10A of the laser diode array 10 is laser diode group one, including three laser diodes with the same center wavelength, and the second row 10B is laser diode group two, including three laser diode groups with the same center wavelength but the center of laser diode group one Laser diodes of different wavelengths. The substrate 20 may be made of alumina ceramic material with...

Embodiment 2

[0043] An embodiment of the present invention also provides a laser projector, which includes the semiconductor laser light source provided in Embodiment 1 of the present invention. Figure 4 Shown here is a schematic structural diagram of a laser projector described in this embodiment, which includes a semiconductor laser light source 100, a heat dissipation device 104, an opto-mechanical module 110, and a lens 120. The semiconductor laser light source 100 includes three semiconductor laser light sources, namely a first semiconductor laser light source 101, a second semiconductor laser light source 102 and a third semiconductor laser light source 103, which respectively output blue laser, green laser and red laser. The three semiconductor laser light sources are arranged on the heat sink 104 independently of each other. The heat dissipation device 104 may be a combination of a heat dissipation fan and a heat sink made of aluminum, copper or alloy materials, or may be other typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com