Lu203 rare earth element modified NTC semiconductor ceramic thermosensitive chip material with high temperature resistance and high reliability

A chip material, heat-sensitive technology, applied in the field of resistance materials, can solve problems such as drift, difficulty in stability, temperature error, etc., achieve stable resistance and B value, improve high temperature resistance performance and reliability, temperature resistance and reliability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Lu in this example 2 o 3 The composition of the modified NTC thermosensitive chip material by weight is as follows:

[0024] 25 parts of manganese dioxide, 30 parts of ferric oxide, 35 parts of tricobalt tetroxide, 5 parts of silicon dioxide, 5 parts of zinc, and 5 parts of dilutetium oxide.

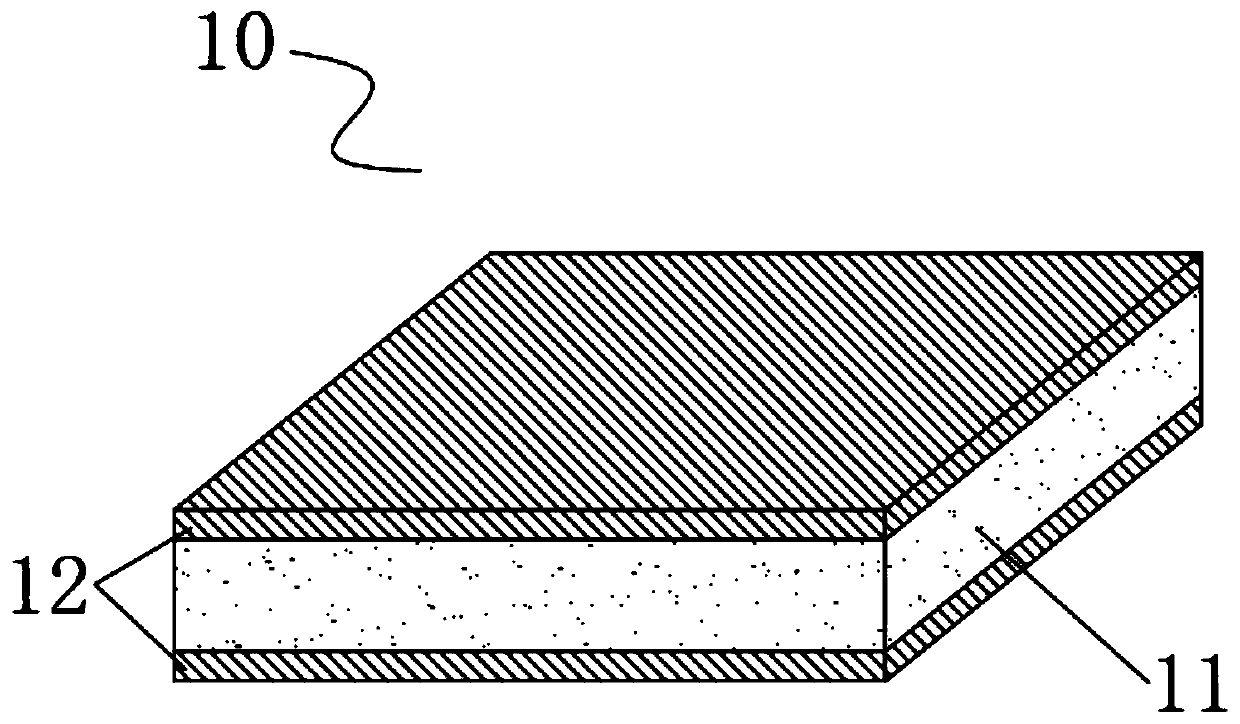

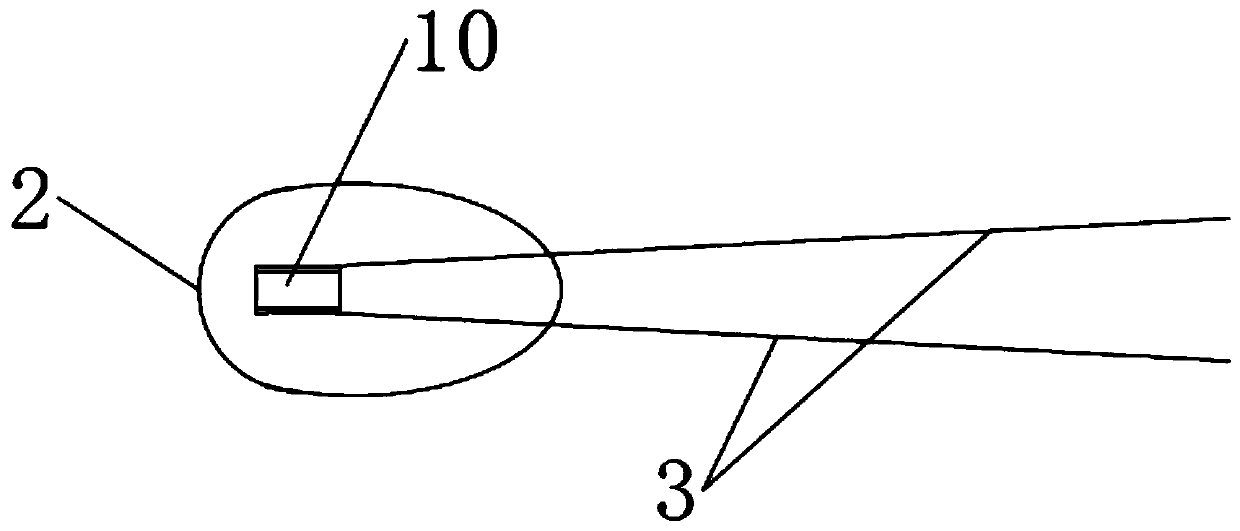

[0025] Use this material to prepare NTC thermistor chips, such as figure 1 As shown, the thermistor chip 10 includes a thermosensitive ceramic substrate 11 and two electrodes 12 respectively arranged on both surfaces of the thermosensitive ceramic substrate 11, and the thermosensitive ceramic substrate 11 is made of this material, so The electrode 12 is made of metal, such as silver.

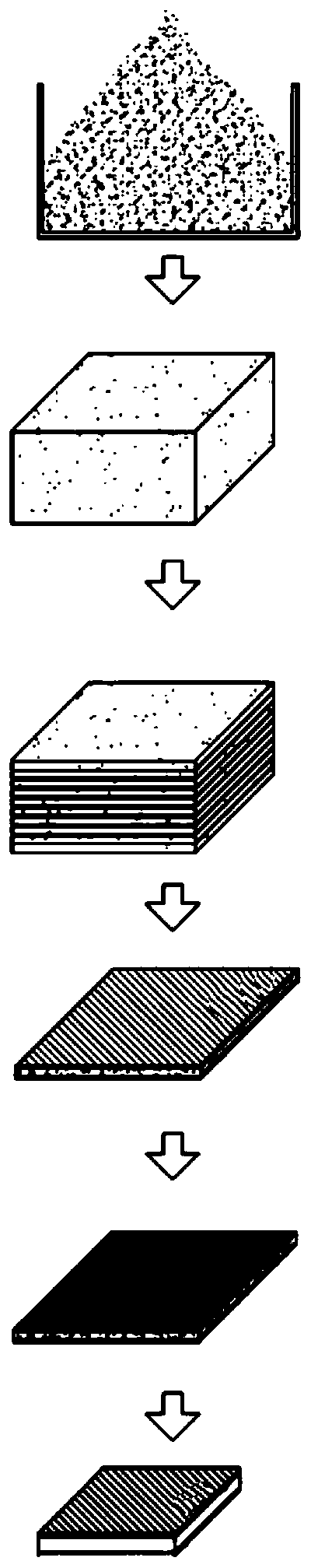

[0026] Such as image 3 Shown, utilize this material to prepare the method for NTC thermistor chip and comprise the steps:

[0027] (1) After mixing the raw materials according to the formula, ball milling, drying, sieving, grinding, drying, and sieving are carried out in sequence to obtain the...

Embodiment 2

[0033] Lu in this example 2 o 3 The composition of the modified NTC thermosensitive chip material by weight is as follows:

[0034] 60 parts of manganese dioxide, 35 parts of tricobalt tetroxide, 3 parts of nickel oxide, 2 parts of aluminum oxide, and 5 parts of dilutetium oxide.

[0035] In this embodiment, the structure and preparation method of the NTC thermistor chip made of this material are the same as those in Embodiment 1.

Embodiment 3

[0037] Lu in this example 2 o 3 The composition of the modified NTC thermosensitive chip material by weight is as follows:

[0038] 65 parts of manganese dioxide, 10 parts of tricobalt tetroxide, and 25 parts of nickel trioxide.

[0039] In this embodiment, the structure and preparation method of the NTC thermistor chip made of this material are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com