Method for preparing heat-sensitive non-combustion tobacco sheet based on kraft lignin

A technology of sulfate lignin and tobacco sheet, which is applied in the directions of preparing tobacco, tobacco, processing tobacco, etc., can solve problems such as low rate of return, and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

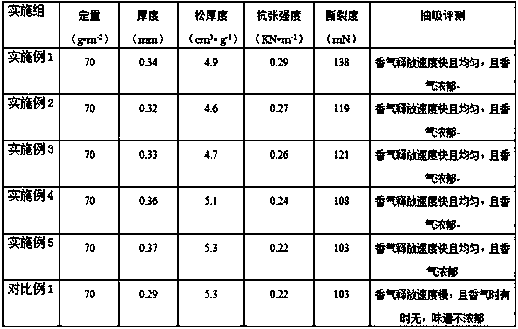

Examples

Embodiment 1

[0026] A method for preparing heat-sensitive non-burning tobacco sheets based on kraft lignin, comprising the following steps:

[0027] (1) Collect the masson pine kraft cooking waste liquor produced during the mixed cooking and pulping process of masson pine, sodium hydroxide and sodium sulfide. Acetic acid was added to masson pine kraft cooking waste liquor to adjust the pH to 4.5 to obtain kraft lignin precipitation.

[0028] (2) Put the wood pulp with a mass fraction of 20% under the action of a deflaker for 10 minutes to obtain a pulp suspension.

[0029] (3) Collect discarded tobacco stems and tobacco flakes, mix and pulverize to obtain tobacco powder.

[0030] (4) According to parts by mass, 100 parts of pulp suspension, 25 parts of smoke powder, 8 parts of mint flavor and 4 parts of kraft lignin precipitation were mixed, and the mixed suspension was obtained under the action of a decomposer for 4 minutes.

[0031] (5) Vacuum filter the mixed suspension under the cond...

Embodiment 2

[0035] A method for preparing heat-sensitive non-burning tobacco sheets based on kraft lignin, comprising the following steps:

[0036] (1) Collect the masson pine kraft cooking waste liquor produced during the mixed cooking and pulping process of masson pine, sodium hydroxide and sodium sulfide. Acetic acid was added to masson pine kraft cooking waste liquor to adjust the pH to 3.0 to obtain kraft lignin precipitation.

[0037] (2) Put the wood pulp with a mass fraction of 10% under the action of a deflaker for 5 minutes to obtain a pulp suspension.

[0038] (3) Collect discarded tobacco stems and tobacco flakes, mix and pulverize to obtain tobacco powder.

[0039] (4) According to parts by mass, mix 100 parts of pulp suspension, 20 parts of smoke powder, 5 parts of mint flavor and 3 parts of kraft lignin precipitation, and obtain a mixed suspension under the action of a decomposer for 2 minutes.

[0040] (5) Vacuum filter the mixed suspension under the condition of a vacuu...

Embodiment 3

[0044] A method for preparing heat-sensitive non-burning tobacco sheets based on kraft lignin, comprising the following steps:

[0045] (1) Collect the poplar kraft cooking waste liquor produced during the mixed cooking and pulping process of poplar chips, sodium hydroxide and sodium sulfide. Acetic acid was added to poplar kraft cooking waste liquor to adjust the pH to 7.0 to obtain kraft lignin precipitation.

[0046] (2) Put the wood pulp with a mass fraction of 30% under the action of a deflaker for 15 minutes to obtain a pulp suspension.

[0047] (3) Collect discarded tobacco stems and tobacco flakes, mix and pulverize to obtain tobacco powder.

[0048] (4) According to parts by mass, 100 parts of pulp suspension, 30 parts of smoke powder, 10 parts of lime essence and 5 parts of kraft lignin precipitation were mixed, and the mixed suspension was obtained under the action of a decomposer for 5 minutes.

[0049] (5) Vacuum filter the mixed suspension under the condition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com