Preparation method of high-hygroscopicity alginate dressing

A technology with high hygroscopicity and alginate, which is applied in the field of medical supplies, can solve problems such as the instability of nano-silver and the high toxicity of human cells, and achieve the effect of promoting wound healing, accelerating the recovery of skin tissue, and improving the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

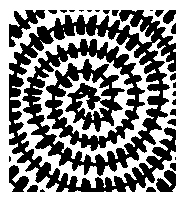

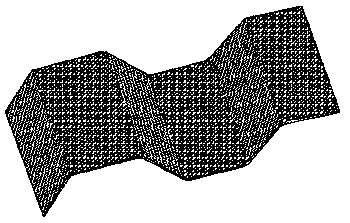

[0024] Such as Figure 1 to Figure 3 The highly hygroscopic alginate dressing of the present invention comprises a dressing body soaked in a soaking solution; the dressing body is made of multilayer alginate fiber monomers through weaving and compounding; the soaking solution includes the following components by weight: Raw materials: 2~5 parts of tea polyphenols, 1~8 parts of aloe extract, 0.005~0.01 parts of recombinant human epidermal growth factor, 1~5 parts of betaine, 100.6~7 parts of polyglycerol and 1~5 parts of carbomer .

[0025] The alginate fiber monomer is calcium alginate fiber prepared by wet spinning from a spinning solution of sodium alginate.

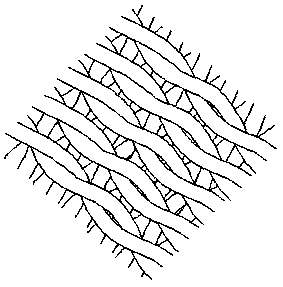

[0026] The calcium alginate fiber is in the form of helical rotating fiber, wave extension or helical cross structure.

[0027] The alginate fiber monomers in the upper and lower adjacent layers are arranged horizontally and vertically.

Embodiment 2

[0029] The structure of the highly hygroscopic alginate dressing of the present invention is the same as that of Example 1, wherein the alginate fiber monomer is calcium alginate fiber prepared by 3D printing from a spinning solution of sodium alginate.

Embodiment 3

[0031] The preparation method of highly hygroscopic alginate dressing of the present invention comprises the following steps:

[0032] The first step is to prepare the soaking solution. According to the ratio, take 3 parts of tea polyphenols, 6 parts of aloe extract, 0.006 parts of recombinant human epidermal growth factor, 3 parts of betaine, 104 parts of polyglycerol and 2 parts of carbomer to add to the formula Stir in deionized water with a total weight ratio of 1:57 at a temperature of 25°C to obtain a uniformly mixed soaking solution;

[0033] The second step is soaking. Soak the dressing body composed of 8 layers of alginate fiber monomers made by wet spinning in the soaking solution, the soaking temperature is 28°C, and the soaking time is 7 hours;

[0034] The third step is to freeze and sterilize, take out the soaked alginate fiber dressing, and place it in a freeze-drying box to freeze-dry; sterilize with ethylene oxide to obtain a suction-type highly hygroscopic al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com