Device and method for treating waste gas with water

A technology for water treatment and waste gas, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as hidden dangers, deprecation, explosion safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

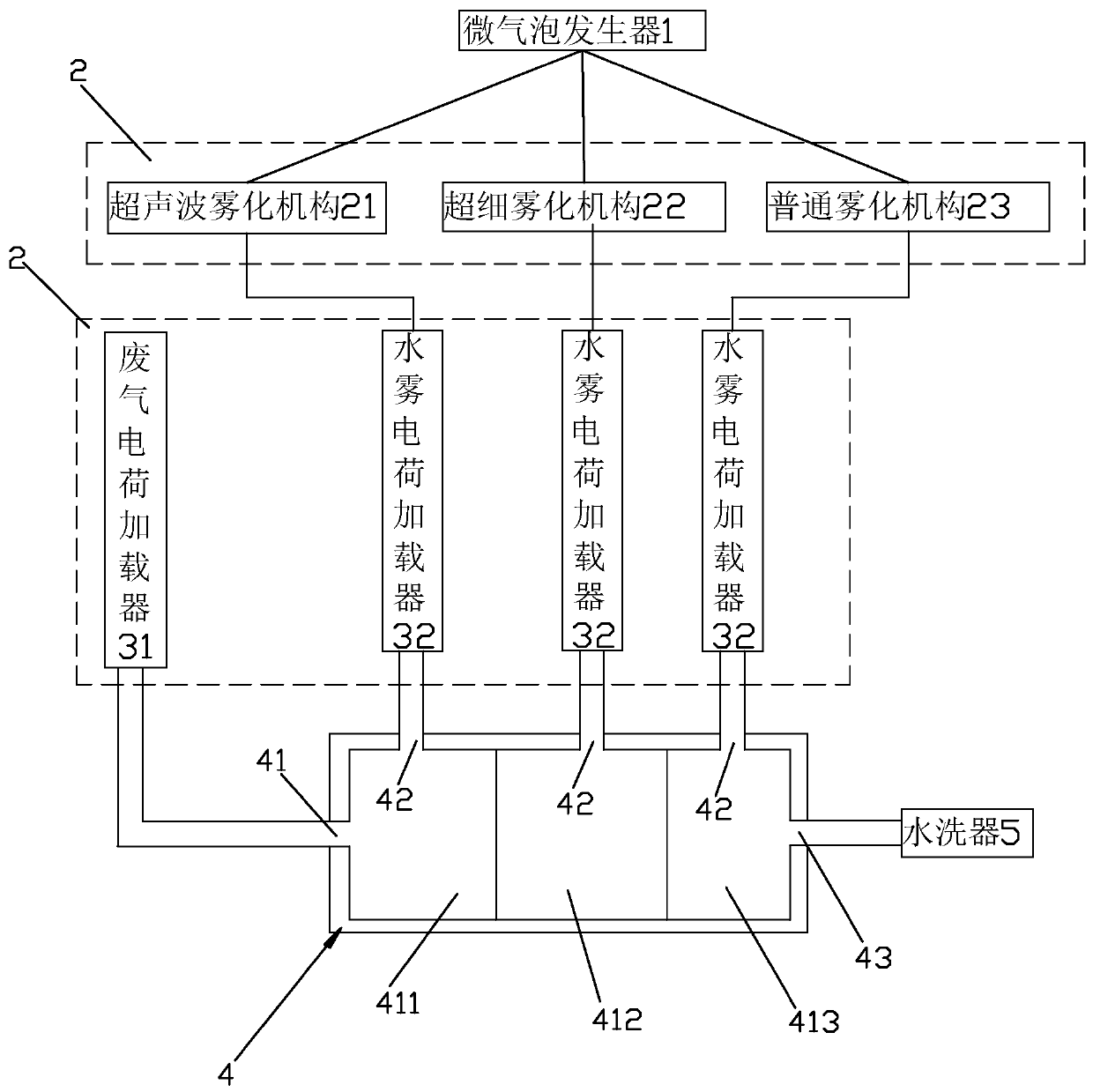

[0027] Please check figure 1 , a device for treating waste gas with water, including a microbubble generator 1 , an atomizer 2 , a charge loader 3 , a mixer 4 and a water scrubber 5 .

[0028] The microbubble generator 1 includes a first container containing water and an electrode group connected to the first container, the electrode group includes an anode and a cathode respectively electrically connected to the positive and negative poles of the power supply, and the electrode group is electrified to generate electrolysis Reacts and creates microbubbles, electrifying water through electrolysis. The microbubble generator 1 is the electrocatalytic oxidation system 2 described in CN2010105633708, or ordinary electrolysis.

[0029] The atomizer 2 is used to generate water mist, and the atomizer 2 includes three atomization mechanisms with different sizes of water mist particles, and one of the three atomization mechanisms is an ultrasonic atomization mechanism 21, One is an ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com