Plugging cone for tundish nozzle and nozzle plugging method

A technology of tundish and blocking cone, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve the problems that the molten steel cannot be blocked, the hidden danger of personal safety of production equipment, etc., and achieve the elimination of potential safety hazards , simple structure, and the effect of preventing the expansion of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

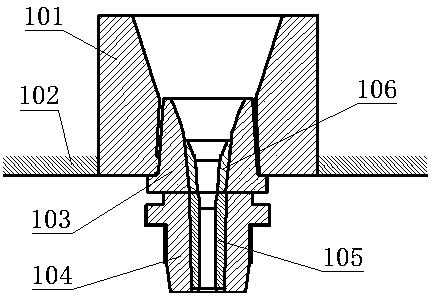

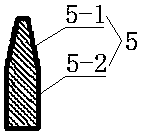

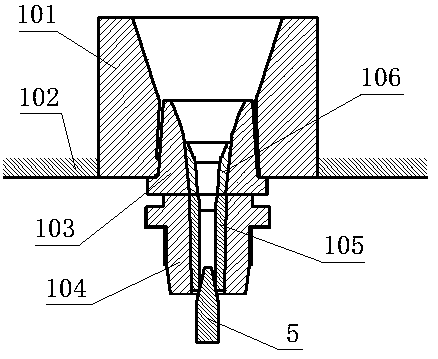

[0020] like Figure 4 A plugging cone for a tundish nozzle as shown includes a plugging cone 1, the plugging cone 1 has a cylindrical part 1-1, the lower end of the cylindrical part 1-1 has a conical plugging part 1-2, and the upper end The steel pipe 2 is connected by spot welding, and the outer diameter of the steel pipe 2 is basically the same as that of the cylinder part 1-1; there is a gap for the liquid to flow through at the joint between the steel pipe 2 and the cylinder part 1-1. The inner cavity of the steel pipe 2 is filled with aluminum particles 3 , and the top of the steel pipe 2 is welded with a handle 4 .

[0021] A kind of tundish nozzle sealing method, comprises using such as Figure 4 The shown tundish nozzle uses a plugging cone, and the specific plugging method is as follows: insert the tundish nozzle plugging cone from above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com