Preparation method of titanium-base Ti4O7 electrode

A technology of titanium suboxide and titanium dioxide, which is applied in the field of electrochemistry, can solve problems such as low process stability, difficult process control, and poor uniformity, and achieve high process stability, high electrochemical oxidation activity, and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

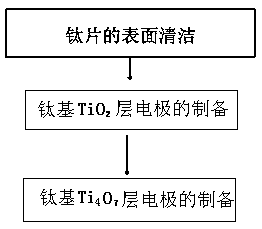

[0021] After the titanium sheet is cut, it is polished on sandpaper for 15 minutes to remove dirt and oxides on the surface of the titanium sheet. Afterwards, the titanium sheet was ultrasonically cleaned in absolute ethanol for 30 min, and then the titanium sheet was vacuum-dried at 60° C. for 2 h.

[0022] Preparation of TiO on the surface of titanium sheet by direct current sputtering 2 layer. Put the cleaned titanium sheet on the anode of the DC sputtering device, and the cathode is pure titanium, vacuumize to 5Pa with a mechanical vacuum pump, and then vacuumize to 10 Pa with a molecular pump. -4 Pa. Then heat the anode titanium sheet to 350°C, pass argon gas into the device, turn on the power to clean the cathode pure titanium for 15 minutes, and remove the oxide on the surface of the cathode pure titanium. Oxygen is introduced into the device, the flow ratio of oxygen and argon is 1:16, the air pressure is adjusted to 0.8Pa, the preparation power is 120W, and the pre...

Embodiment 2

[0029] After the titanium sheet is cut, it is polished on sandpaper for 15 minutes to remove dirt and oxides on the surface of the titanium sheet. Afterwards, the titanium sheet was ultrasonically cleaned in absolute ethanol for 30 min, and then the titanium sheet was vacuum-dried at 60° C. for 2 h.

[0030] Preparation of TiO on the surface of titanium sheet by DC sputtering method 2 layer. Put the cleaned titanium sheet on the anode of the DC sputtering device, and the cathode is pure titanium, vacuumize to 5Pa with a mechanical vacuum pump, and then vacuumize to 10 Pa with a molecular pump. -4 Pa. Then heat the anode titanium piece to 360°C, pass argon gas into the device, turn on the power to clean the cathode pure titanium for 15 minutes, and remove the oxide on the surface of the cathode pure titanium. Oxygen is introduced into the device, the flow ratio of oxygen and argon is 1:19, the air pressure is adjusted to 0.9Pa, the preparation power is 110W, and the preparat...

Embodiment 3

[0037] After the titanium sheet is cut, it is polished on sandpaper for 15 minutes to remove dirt and oxides on the surface of the titanium sheet. Afterwards, the titanium sheet was ultrasonically cleaned in absolute ethanol for 30 min, and then the titanium sheet was vacuum-dried at 60° C. for 2 h.

[0038] Preparation of TiO on the surface of titanium sheet by direct current sputtering 2 layer. Put the cleaned titanium sheet on the anode of the DC sputtering device, and the cathode is pure titanium, vacuumize to 5Pa with a mechanical vacuum pump, and then vacuumize to 10 Pa with a molecular pump. -4 Pa. Then heat the anode titanium piece to 340°C, pass argon gas into the device, turn on the power to clean the cathode pure titanium for 15 minutes, and remove the oxide on the surface of the cathode pure titanium. Oxygen is introduced into the device, the flow ratio of oxygen and argon is 1:13, the air pressure is adjusted to 0.7Pa, the preparation power is 130W, the prepara...

PUM

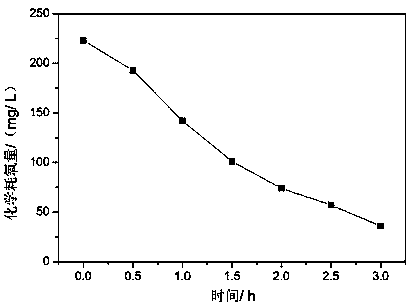

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

| oxygen consumption | aaaaa | aaaaa |

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com