Tannin extract waxy leather and manufacturing method thereof

A production method and tannin extract technology, which are applied in the directions of dyeing, leather dipping, leather surface treatment, etc., can solve the problems of poor washing resistance of tannin extract leather, poor softness of extract extract leather, and no wax skin of extract extract oil, etc. Reduced soaking time, soft hand feel, best washability and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

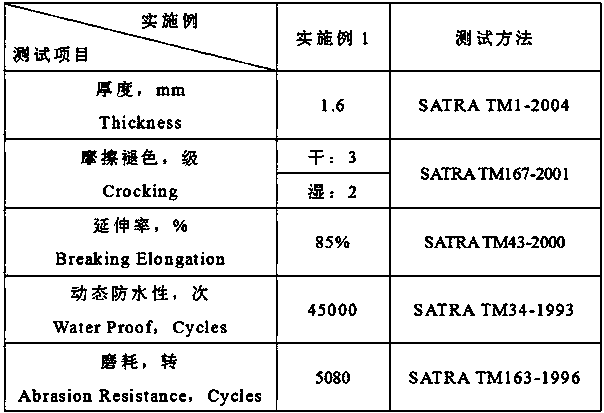

Embodiment 1

[0052] A preparation method of tannin extract wax skin, comprising the steps of:

[0053] The wet blue skin is rewetted→first retanning→alkali extraction→secondary retanning→prefatliquoring→dyeing→drying→softening→skinning→rolling, the details are as follows:

[0054] Step 1, rewetting: put the wetblue hide in the drum, add 200% water, 0.5% rehumidifying agent Usabang W, and 0.6% degreasing agent LIPIDOL DA according to the mass percentage of the wetblue hide , run for 48min, add 1.0% acid softening enzyme TJ-A488, 1.2% ammonium bisulfate, run for 90min, add 0.5% formic acid, run for 40min, add 1.2% anti-spot agent TJ-A971, run for 60min, add 0.78 % oxalic acid, run for 60 minutes, drain, add 300% water, wash with water and drain, and get wet leather;

[0055] Step 2, primary retanning: according to the mass percentage of wet blue leather, add 100% water and 0.5% formic acid into the drum, adjust the pH to 2.8-3.2, run for 40 minutes, and add 1.0% syntan agent SYNTAN TS150 , 4...

Embodiment 2

[0062] A preparation method of tannin extract wax skin, comprising the steps of:

[0063] The wet blue skin is rewetted→first retanning→alkali extraction→secondary retanning→prefatliquoring→dyeing→drying→softening→skinning→rolling, the details are as follows:

[0064] Step 1, rewetting: put the wetblue hide in the drum, add 150% water, 0.4% rehumidifying agent Usabang W, and 0.5% degreasing agent LIPIDOL DA according to the mass percentage of the wetblue hide , run for 45 minutes, add 0.9% acid softening enzyme TJ-A488, 1.1% ammonium bisulfate, run for 85 minutes, add 0.4% formic acid, run for 35 minutes, add 1.0% anti-spot agent TJ-A971, run for 55 minutes, add 0.7 % oxalic acid, run for 55 minutes, drain, add 250% water, wash with water and drain, and get wet leather;

[0065] Step 2, primary retanning: according to the mass percentage of wet blue leather, add 95% water and 0.4% formic acid into the drum, adjust the pH to 2.8-3.2, run for 35 minutes, and add 0.8% syntan tan...

Embodiment 3

[0072] A preparation method of tannin extract wax skin, comprising the steps of:

[0073] The wet blue skin is rewetted→first retanning→alkali extraction→secondary retanning→prefatliquoring→dyeing→drying→softening→skinning→rolling, the details are as follows:

[0074] Step 1, rewetting: put the wetblue hide in the drum, add 250% water, 0.6% rehumidifying agent Usabang W, and 0.7% degreasing agent LIPIDOL DA according to the mass percentage of the wetblue hide , run for 50 minutes, add 1.1% acid softening enzyme TJ-A488, 1.3% ammonium bisulfate, run for 95 minutes, add 0.6% formic acid, run for 45 minutes, add 1.3% anti-spot agent TJ-A971, run for 65 minutes, add 0.9 % oxalic acid, run for 65 minutes, drain, add 350% water, wash with water and drain to get wet leather;

[0075] Step 2, primary retanning: according to the mass percentage of wet blue leather, add 105% water and 0.6% formic acid into the drum, adjust the pH to 2.8-3.2, run for 45 minutes, add 1.2% syntan TS150 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com