High-strength cast steel and manufacturing method thereof

A manufacturing method and high-strength technology, applied to the improvement of process efficiency, electric furnace, furnace, etc., can solve the problems of increased maintenance costs, high wear rate, frequent replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, and the mode of the present invention includes but not limited to the following examples.

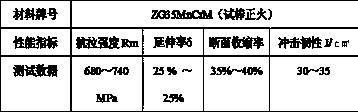

[0019] A high-strength cast steel, which contains chemical elements and their mass percentages: carbon 0.35-0.40%, silicon 0.35-0.6%, manganese 1.2-1.4%, chromium 0.4-0.6%, phosphorus ≤ 0.035%, sulfur ≤ 0.035%, aluminum 0.03-0.08%, titanium 0.02-0.06%.

[0020] The manufacturing method of described high-strength cast steel comprises the following steps:

[0021] (1) Throw steel scrap, ferromanganese, aluminum wire, pig iron, ferrochrome, and ferrotitanium into an intermediate frequency electric furnace for smelting at a melting temperature of 1600-1650°C, and the smelting molten steel reaches 80-90% of the furnace capacity;

[0022] (2) Molten steel slag removal: remove slag from the molten steel in step (1), the amount of slag removal agent used is 0.1% to 0.3% of the weight of the molten st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com