Production process of crane boom steel pipe

A production process and crane technology, applied in the improvement of process efficiency, furnace type, furnace and other directions, can solve the problems of unstable impact toughness at low temperature of steel pipes, and achieve uniform and stable impact performance, promote floating, and uniform molten steel temperature and composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A crane jib steel pipe production process, one batch produces five furnaces of steel, the tube billet manufacturing method includes electric furnace smelting, LF refining, VD vacuum treatment, continuous casting, blanking, and rolling to obtain the tube billet. Steel pipe processing methods include: cutting, heating, piercing, rolling, normalization, sizing, heat treatment, straightening, shot blasting, flaw detection, testing, etc. to obtain finished steel pipes. details as follows:

[0059] Step S1, molten steel smelting: first, the blast furnace smelts coke and ore into molten iron that meets the requirements, then puts the molten iron and steel scrap into the electric furnace, blows oxygen into the molten pool of the electric furnace, and adds lime to form slag. When the temperature is not higher than 1560°C, the phosphorus content in the steel is removed by slag replacement and furnace door slag flow. When the tapping carbon and tapping phosphorus meet the target ...

Embodiment 2

[0096] Another crane jib steel pipe production process, compared with Case 1, only the specification of the finished steel pipe and the heat treatment holding time in this embodiment are different. The finished product specification of this example is The heat treatment process is: 940°C, heat preservation for 80min, water quenching, tempering at 650°C, heat preservation for 160min. The mechanical properties and low-temperature impact energy were tested, as shown in Table 4, which also all meet the mechanical property requirements of steel pipes and meet the production needs.

[0097] Table 4 Mechanical properties of steel pipes

[0098]

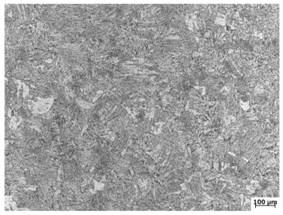

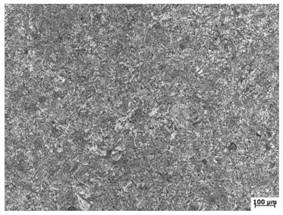

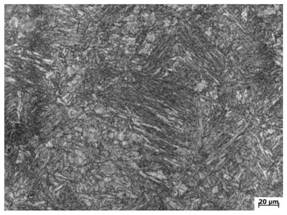

[0099] From the implementation cases 1 and 2, it can be seen that by controlling the various links of smelting-continuous casting-rolling, round steel with qualified composition and uniform structure can be obtained. After the round steel is heated, pierced, rolled, normalized, sized, and heat treated, a steel pipe with stable mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com