Hydraulic device for cooling at least two wet-running clutches in motor vehicle

A wet clutch and hydraulic device technology, applied in the field of hydraulic devices, can solve undesired problems and achieve the effect of avoiding excessive supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

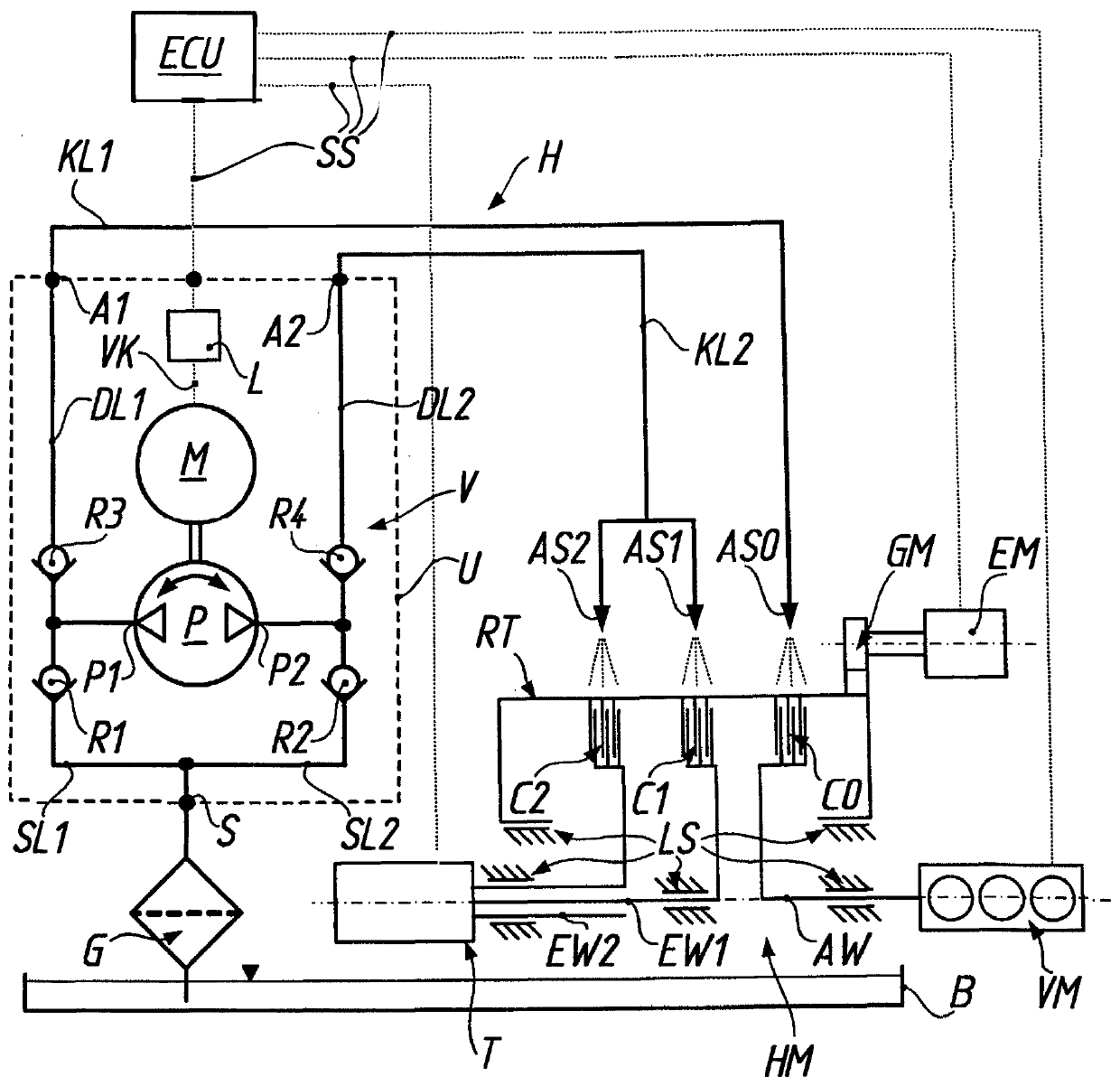

[0021] exist figure 1 , reference numeral H generally identifies a hydraulic device for cooling at least two (in the exemplary embodiment shown, three) wet clutches C0 , C1 , C2 in a motor vehicle. In this case, the three clutches C0, C1, C2 are hybrid transmission module HM (only in figure 1 shown schematically in ), which in particular comprises a dual clutch arrangement with first and second (partial) clutches C1, C2 for shifting of an automatically shifted transmission T (dual clutch transmission) and for coupling or Specifically the (disconnecting) clutch C0 of the internal combustion engine VM is disengaged. In this case, a corresponding actuation system (not shown) is associated with each clutch C0, C1, C2 for independent actuation.

[0022] The rotating part RT of the hybrid transmission module HM is permanently drivingly connected to the electric motor EM via the transmission mechanism GM, the rotating part RT can be alternately drivingly connected to the output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com