A Processing Technology of Paul Combination Prism

A processing technology and prism technology, which is applied in the field of Paul combined prism processing technology, can solve the problems of low qualified rate of finished products and poor precision of Paul combined prisms, and achieve the effects of simple processing procedure, reduced material scrap rate, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

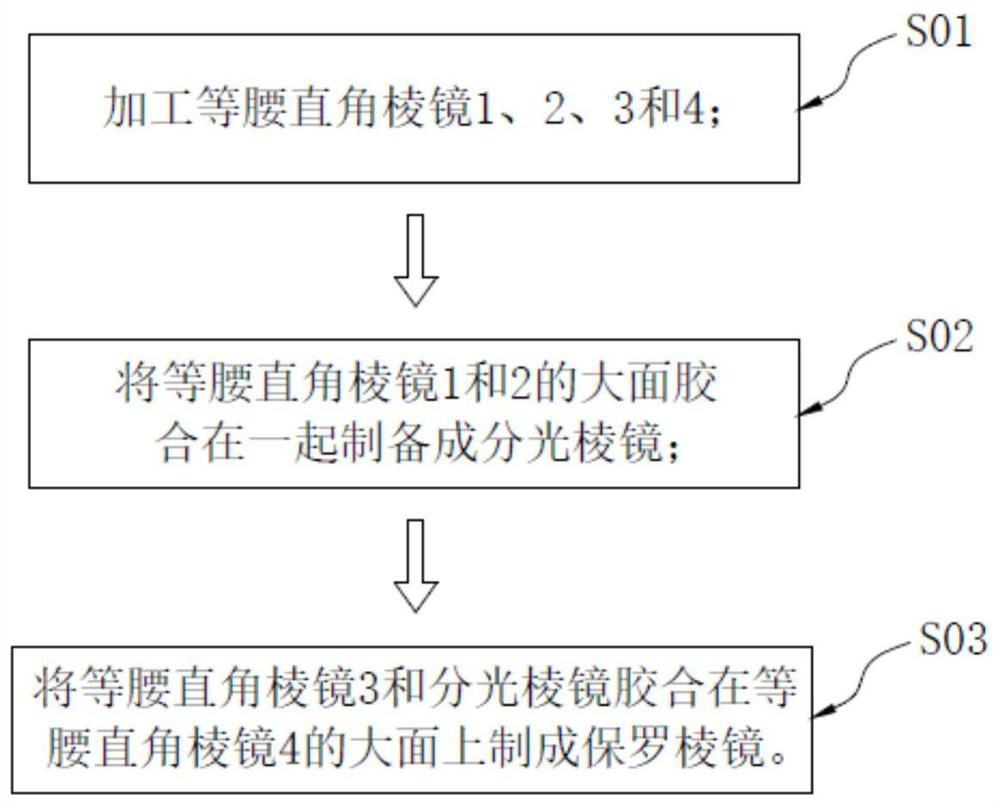

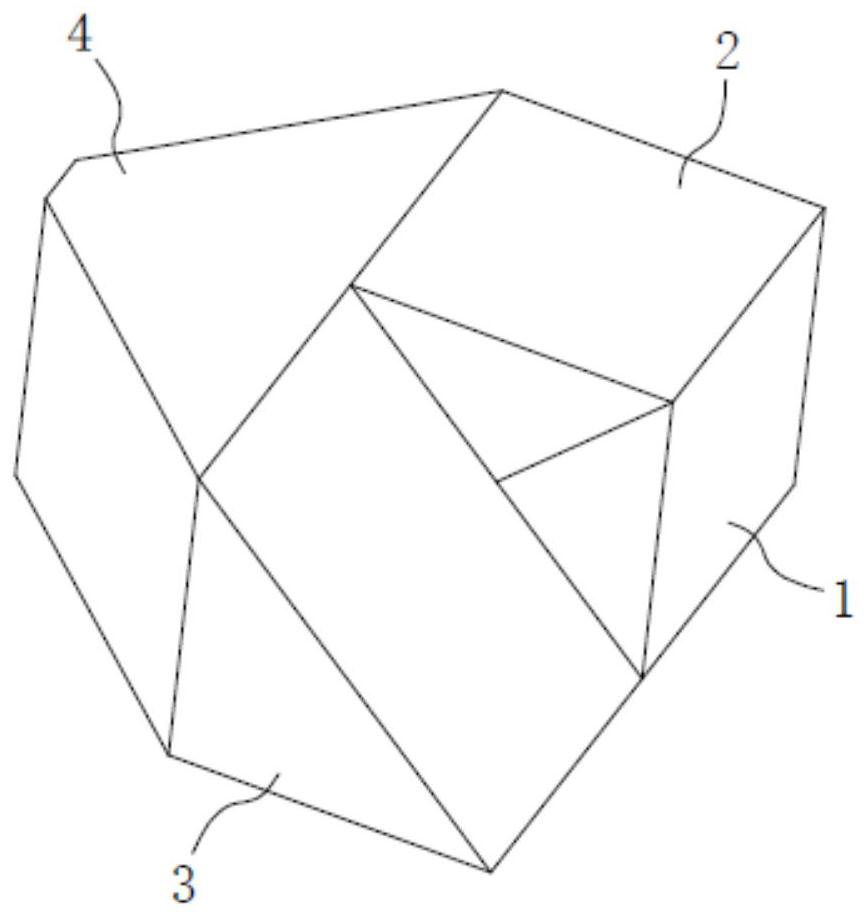

[0058] A kind of Paul combination prism processing technique in the present embodiment, as figure 2 As shown in , the Paul combination prism is composed of isosceles right-angle prisms glued together, and the isosceles right-angle prisms include isosceles right-angle prism I1, isosceles right-angle prism II2, isosceles right-angle prism III3 and isosceles right-angle prism IV4. Steps such as figure 1 As shown in , the specific steps are as follows:

[0059] S01. Processing isosceles rectangular prism:

[0060] ⅰ. Grinding and polishing to produce isosceles right-angle prism I1, isosceles right-angle prism II2 and isosceles right-angle prism III3 with side length of 10×10mm, and isosceles right-angle prism IV4 with side length of large face 10×20mm; Control the technological parameters of each described isosceles right-angled prism to be: the precision of 45 ° of angles, 90 ° of angles and tower difference is all controlled within 8 ", and the verticality of large face and t...

Embodiment 2

[0068] A kind of Paul combination prism processing technique in the present embodiment, the structure of described Paul combination prism is the same as in embodiment 1, and processing steps are as follows:

[0069] S01. Processing isosceles rectangular prism:

[0070] ⅰ. Grinding and polishing to produce isosceles right-angle prism I1, isosceles right-angle prism II2 and isosceles right-angle prism III3 with side length of 20×20mm, and isosceles right-angle prism IV4 with side length of large face 20×40mm; The process control of each described isosceles right-angled prism is: the precision of 45 ° angle, 90 ° angle and tower difference is all controlled within 10 ", and the perpendicularity of large face and two right-angled faces and the side of the triangle is controlled within 30 ", and the size The tolerance is ±0.02mm; the surface flatness of the large surface is ≤1 / 10λ, and the surface finish is 15-20; the surface flatness of the two right-angle surfaces is ≤1 / 8λ, and t...

Embodiment 3

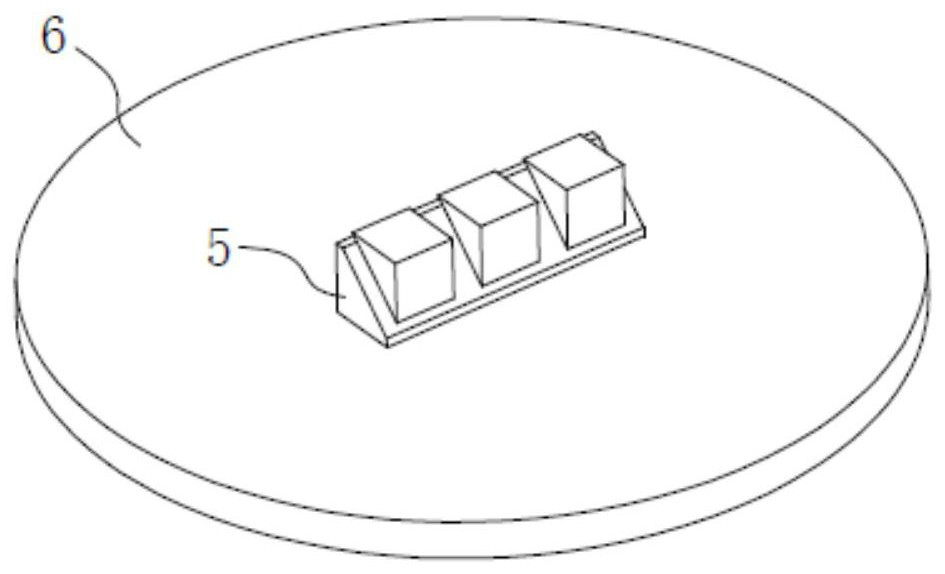

[0078] Paul combination prism processing technology in the present embodiment, processing step is basically the same as embodiment 1 and 2, difference and improvement are, as image 3 Shown in, the processing method of described isosceles rectangular prism is as follows:

[0079] ⅰ. Bond the blank to the large surface of the triangular prism support body 5 with optical glue, keep the large surface of the blank facing up, and then optically glue the right-angled surface at the bottom of the triangular prism support body 5 to a circular tray with a diameter of 300mm 6, and then grind and polish the large face of the blank;

[0080] ⅱ. Clean the processed large surface with ethanol: ether=1:3 mixed reagent, then glue the large surface of the blank to the large surface of the triangular prism by the body 5, and ensure that a right-angled surface of the blank is facing upwards, Then glue the right-angle surface of the bottom of the triangular prism body 5 onto the circular tray 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com