System and method for purifying and recycling HCL-containing waste gas

A waste gas purification and waste gas technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of high treatment cost, complicated HCL-containing waste gas purification process, waste of useful components, etc., to reduce investment and operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are presented to illustrate certain embodiments of the invention and should not be construed as limiting the scope of the invention. The content disclosed in the present invention can be improved simultaneously from materials, methods and reaction conditions, and all these improvements should fall within the spirit and scope of the present invention.

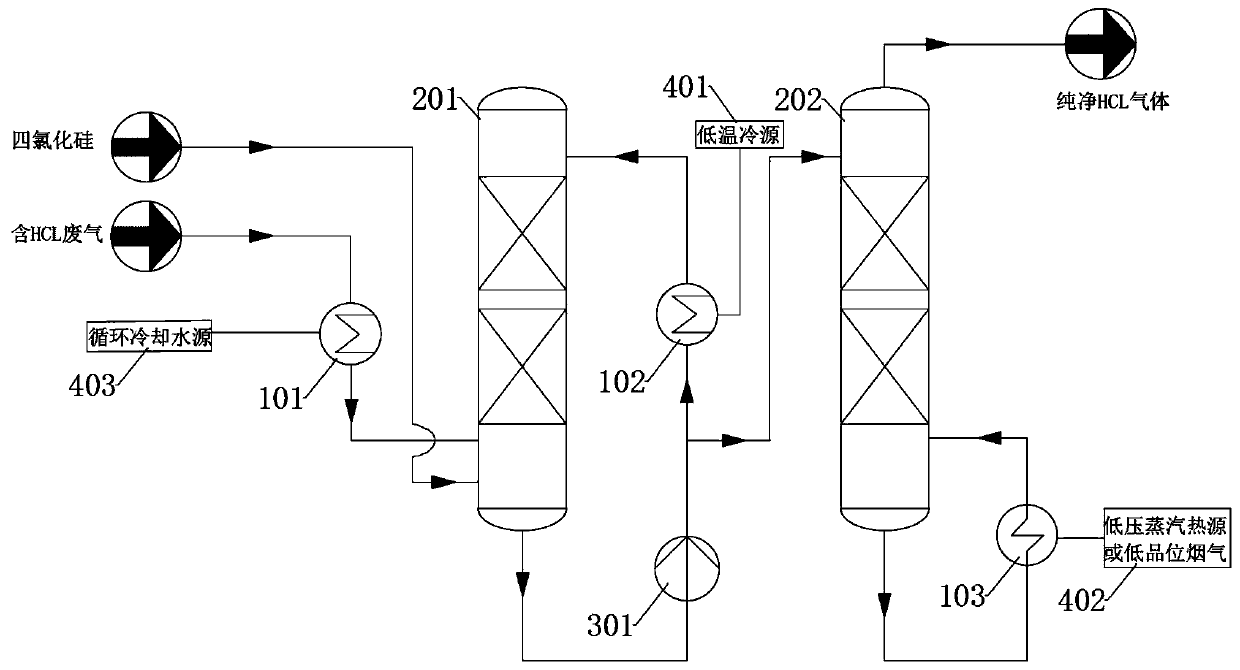

[0025] Such as figure 1 As shown, a system for purifying and recovering waste gas containing HCL includes an absorption tower 201 and a stripping tower 202. The lower inlet of the absorption tower 201 communicates with waste gas containing HCL and silicon tetrachloride liquid through pipelines respectively. Also be provided with the first heat exchanger 101 on the communicating pipeline between HCL waste gas and absorption tower 201, described first heat exchanger 101 is connected with circulating cooling water source 401, and the bottom outlet of described absorption tower 201 is connected with cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com