Collecting agent for recovering copper-lead-zinc minerals from iron tailings

A collector and copper recovery technology, applied in flotation, solid separation and other directions, can solve the problems of poor floatability of non-ferrous metal minerals, change of non-ferrous metal mineral floatability, and low recovery rate of non-ferrous metals, etc. Flotation environment, efficient and fast flotation, and the effect of improving flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The tailings of a certain iron beneficiation contain 0.35% copper and 4.17% sulfur. Ester-215 is used to comprehensively recover copper.

[0014] Step 1: Add 20 parts of acrylonitrile diethyl dithiocarbamate, 20 parts of propionitrile n-butyl xanthate, 10 parts of dibutyl ammonium dithiophosphate, and 20 parts of pine oil into a container at room temperature Press and stir for 30 minutes to make ester-215;

[0015] Step 2: Adjust the tailings to a pH value of 12, add the ester-215 prepared in step 1 and stir for two minutes to float copper, and after twice beneficiation, copper concentrate can be obtained. The technical indicators are shown in Table 1.

Embodiment 2

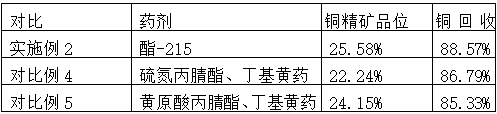

[0025] The tailings of a certain iron beneficiation contain 0.42% copper and 1.05% sulfur. Ester-215 is used to comprehensively recover copper.

[0026] Step 1: Add 35 parts of acrylonitrile diethyl dithiocarbamate, 35 parts of propionitrile n-butyl xanthate, 15 parts of dibutyl ammonium dithiophosphate, and 15 parts of pinitol oil into the container at room temperature Ester-215 can be prepared by stirring at normal pressure for 40 minutes;

[0027] Step 2: Adjust the tailings to a pH value of 8, add the ester-215 produced in step 1 and stir for two minutes to float copper, and after twice beneficiation, copper concentrate can be obtained. The technical indicators are shown in Table 2.

Embodiment 3

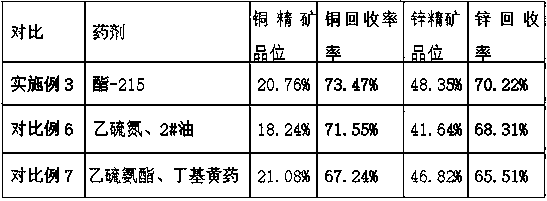

[0035] The tailings of an iron beneficiation contain 0.32% copper, 0.92% zinc and 1.74% sulfur, and the copper and zinc are comprehensively recovered by ester-215.

[0036] Step 1: Add 40 parts of acrylonitrile diethyl dithiocarbamate, 40 parts of propionitrile n-butyl xanthate, 25 parts of dibutyl ammonium dithiophosphate, and 20 parts of pinitol oil into the container at room temperature Ester-215 can be prepared by stirring at normal pressure for 60 minutes;

[0037] Step 2: Adjust the tailings to a pH value of 13, add the ester-215 prepared in step 1 and stir for two minutes to float copper and zinc, and after separation after separation, copper concentrate and zinc concentrate can be obtained. See Table 3 for technical indicators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com