Traceable pipeline

A pipeline and tracer technology, applied in the pipeline field, can solve the problems of lower efficiency, increased maintenance costs, and metal wires are easily corroded, and achieve the effects of simplifying the production process, improving production efficiency and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

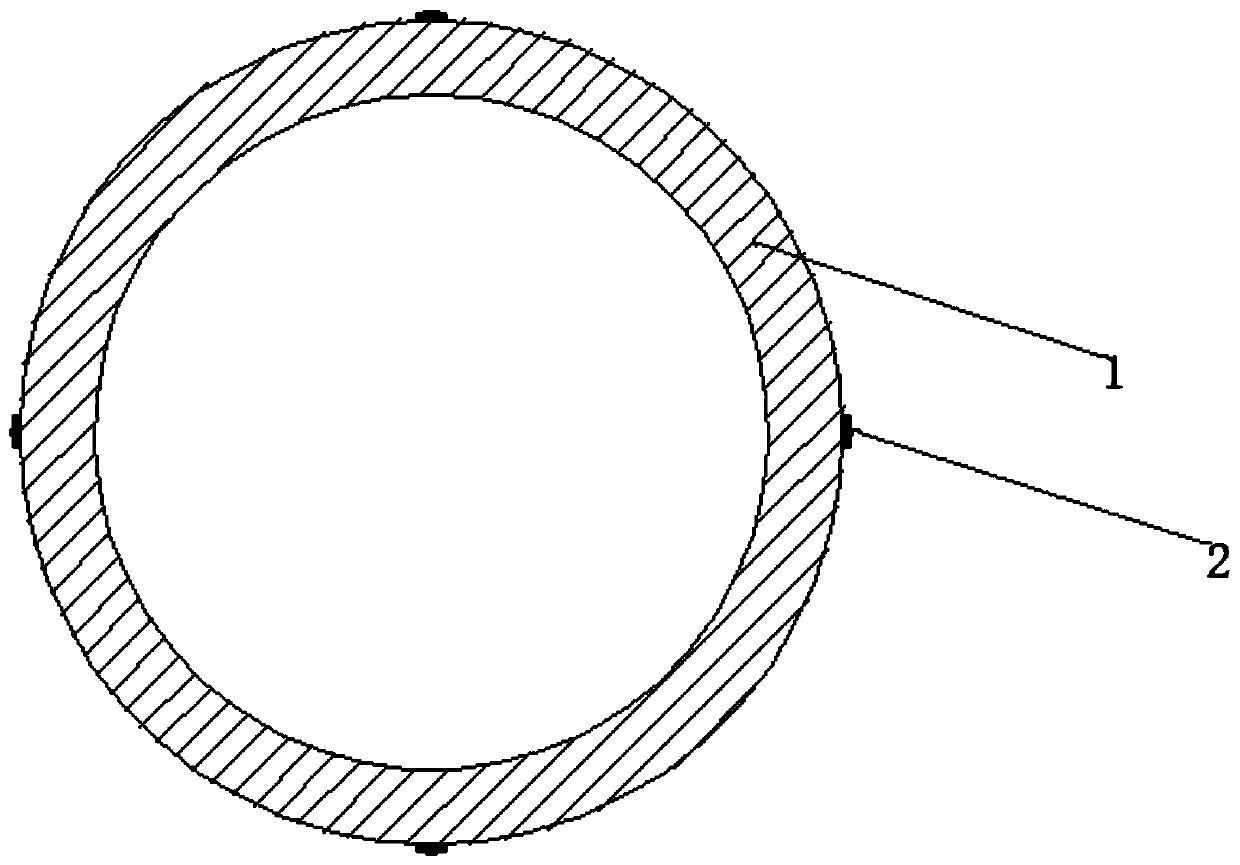

Image

Examples

Embodiment 1

[0023] Take 15% of toner, 0.5% of silane coupling agent, 2.5% of PE wax, 2% of oleic acid amide, 60% of EVA resin, 20% of NdFeB magnetic powder, fully mix them, and extrude Machine, drawing machine, granulator and dryer to make masterbatches containing magnetic powder.

[0024] 80% PE / PP material, 3% masterbatch, 1% antioxidant 1010, 1% antioxidant 168, 5% POE, 1% nano calcium carbonate, 0.1% fluorine processing aid Put the mixed material into the co-extrusion extruder, and at the same time put the prepared masterbatch containing magnetic powder into the color marking machine and extrude it with the co-extrusion extruder on the outer wall of the pipe body in a hot melt state to form a tracer line; After the pipe is extruded, it enters the vacuum sizing device for sizing, and the pipe is cooled by the spray device, so that the tracer line and the pipe body are integrated after cooling; the pipe is pulled out by the tractor to make a visible tracked pipeline.

Embodiment 2

[0026] Take 15% of toner, 0.5% of silane coupling agent, 2.5% of PE wax, 2% of oleic acid amide, 60% of LDPE resin, 20% of NdFeB magnetic powder, fully mix them, and extrude Machine, drawing machine, granulator and dryer to make masterbatches containing magnetic powder.

[0027] 100% PE / PP material, 5% pipe color masterbatch, 7% antioxidant 1010, 5% antioxidant 168, 15% POE, 10% nano calcium carbonate, 2% fluorine processing aid Put the ingredients into the co-extrusion extruder, and at the same time, put the masterbatch containing magnetic powder into the color marking machine and extrude it with the co-extrusion extruder on the outer wall of the pipe body in a hot melt state to form a tracer After the pipe is extruded, it enters the vacuum sizing device for sizing, and the pipe is cooled by the spray device, so that the tracer line and the pipe body are integrated after cooling; the pipe is pulled out by the tractor to make Traceable pipeline.

Embodiment 3

[0029] Take 15% of toner, 0.5% of silane coupling agent, 2.5% of PE wax, 2% of ethylene bis stearic acid amide, 60% of LDPE resin, 20% of iron oxide magnetic powder, fully mix, The masterbatch containing magnetic powder is made through extruder, drawing machine, granulator and dryer.

[0030] 80% PE / PP material, 3% masterbatch, 1% antioxidant 1010, 1% antioxidant 168, 10% SBS, 1% talc, 1% silicone additives Put the mixed material into the co-extrusion extruder, and at the same time put the prepared masterbatch containing magnetic powder into the color marking machine and extrude it with the co-extrusion extruder on the outer wall of the pipe body in a hot melt state to form a tracer line; After the pipe is extruded, it enters the vacuum sizing device for sizing, and the pipe is cooled by the spray device, so that the tracer line and the pipe body are integrated after cooling; the pipe is pulled out by the tractor to make a visible tracked pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com