Production equipment and production process of thermoplastic continuous carbon fiber unidirectional tape

A production equipment and carbon fiber technology, applied in the field of production equipment and production technology of thermoplastic continuous carbon fiber unidirectional tape, can solve the problems of unstable performance, single type of resin, low content of continuous fiber resin, etc., to achieve reduced porosity and uniform thickness , high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

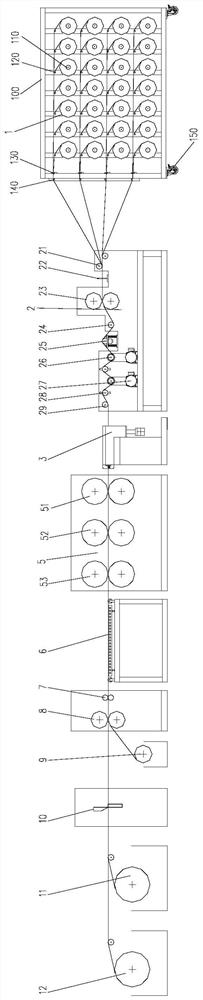

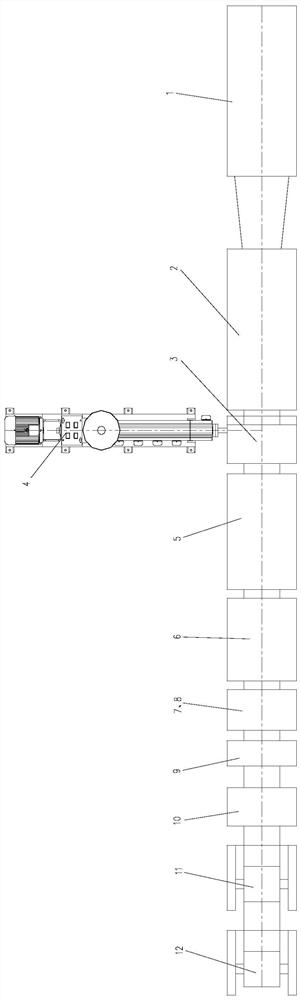

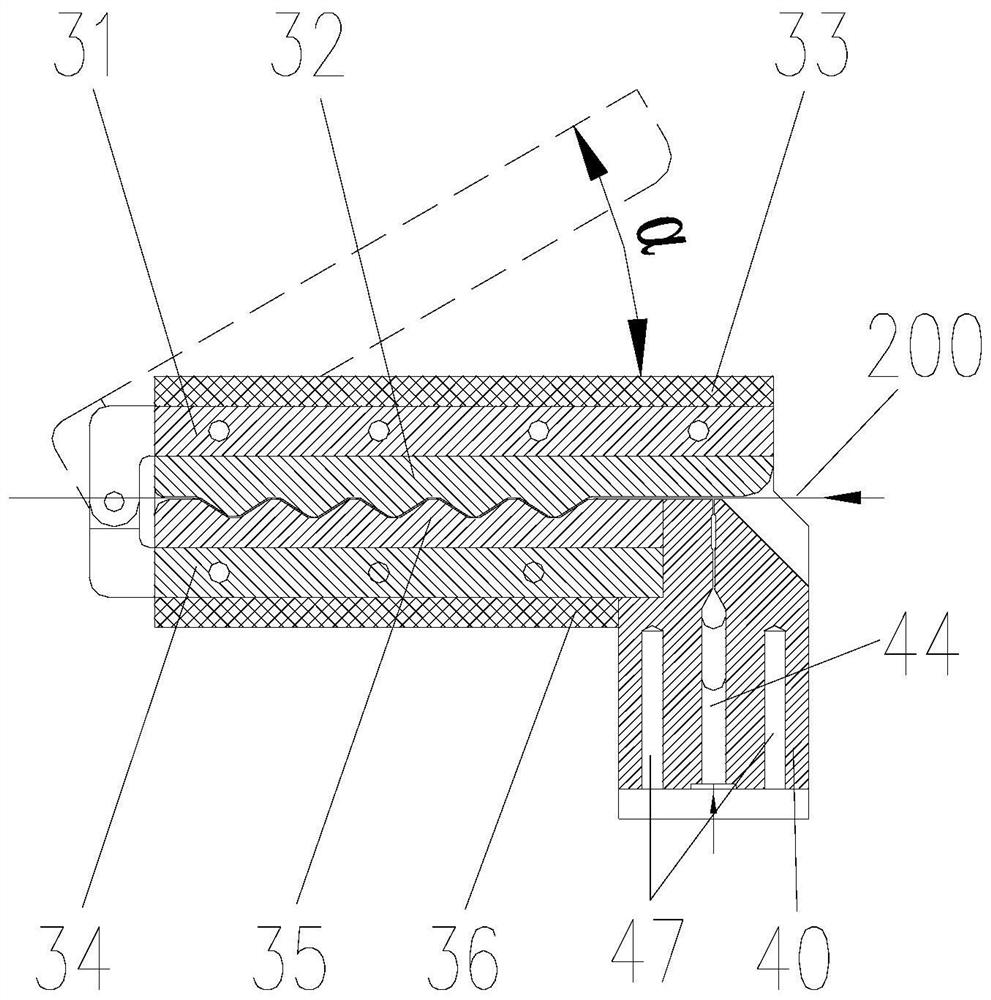

[0035] see Figure 1 to Figure 4 , the production equipment of thermoplastic continuous carbon fiber unidirectional belt of the present invention, comprises the fiber unwinding device 1 that arranges in sequence, yarn spreading mechanism 2, dipping device 3, flattening mechanism 5, cooling plate 6, trimming device 7, traction roller 8. Two waste edge winding machines 9, a transverse cutting machine 10 and a winding device 11.

[0036] The fiber unwinding device 1 includes a frame 100, two groups of yarn bobbin mandrels 110, two groups of yarn guide rollers 120, two groups of yarn guide porcelain eyes 130, two groups of transition yarn rollers 140 and four moving wheels 150; wherein, the frame It includes a rectangular main frame composed of a top plate, a bottom plate, a front end plate and a rear end plate, seven vertical rods connected between the transverse middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com