Control Method of Bucket Wheel Cantilever Stacker and Reclaimer in Strip Coal Yard

A control method and cantilever technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problem that the electrical control method cannot maintain safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0142] A control method for a bucket-wheel cantilever stacker and reclaimer in a strip coal yard. The control system adopted is the network communication of the PROFINET protocol. The master station performs real-time reading and writing of each distributed sub-station, and monitors whether there is an error in the network communication in real time; The control system consists of a master station CPU, 5 distributed test PLC substations, 4 frequency converter substations, 3 encoder substations and 1 touch screen substation;

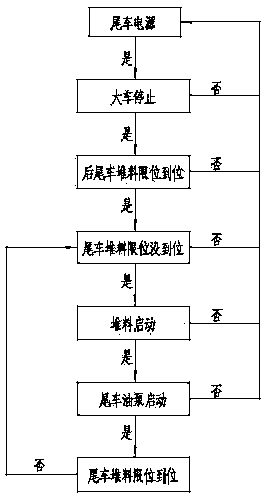

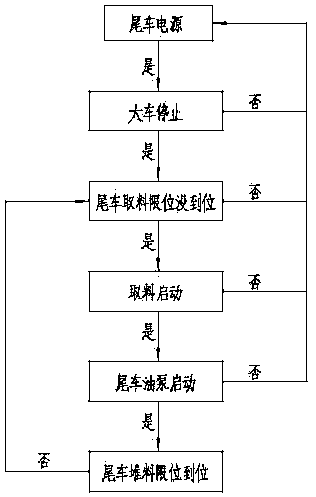

[0143] Control methods include main system control, cantilever belt control, bucket wheel-wheel groove-cab balance control, cart control, movable shovel control, cantilever pitch control, trailer belt control, tail car rear tail car control, and cantilever swing control.

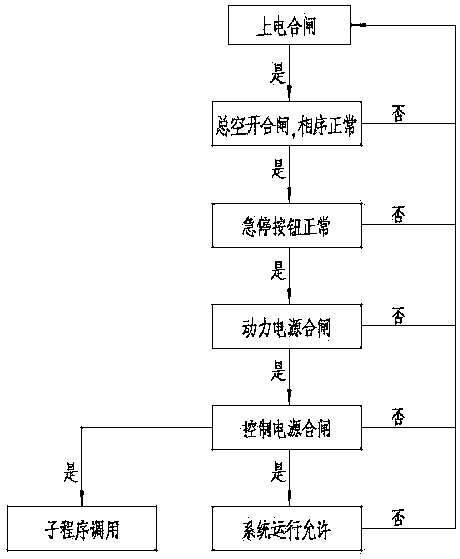

[0144] The main system control includes the following steps:

[0145] (1) PLC power on;

[0146] (2) PLC cyclically scans whether the feedback signal of the main circuit breaker has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com