Preparation process of epoxy resin paint

A technology of epoxy resin coating and preparation process, which is applied in the direction of epoxy resin coating, coating, mixer, etc., which can solve the problem of sticking to the inner wall of the barrel, affecting the effect of cleaning and reusing the discharging barrel, and reducing environmental protection. Efficient and full use of epoxy resin coatings and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

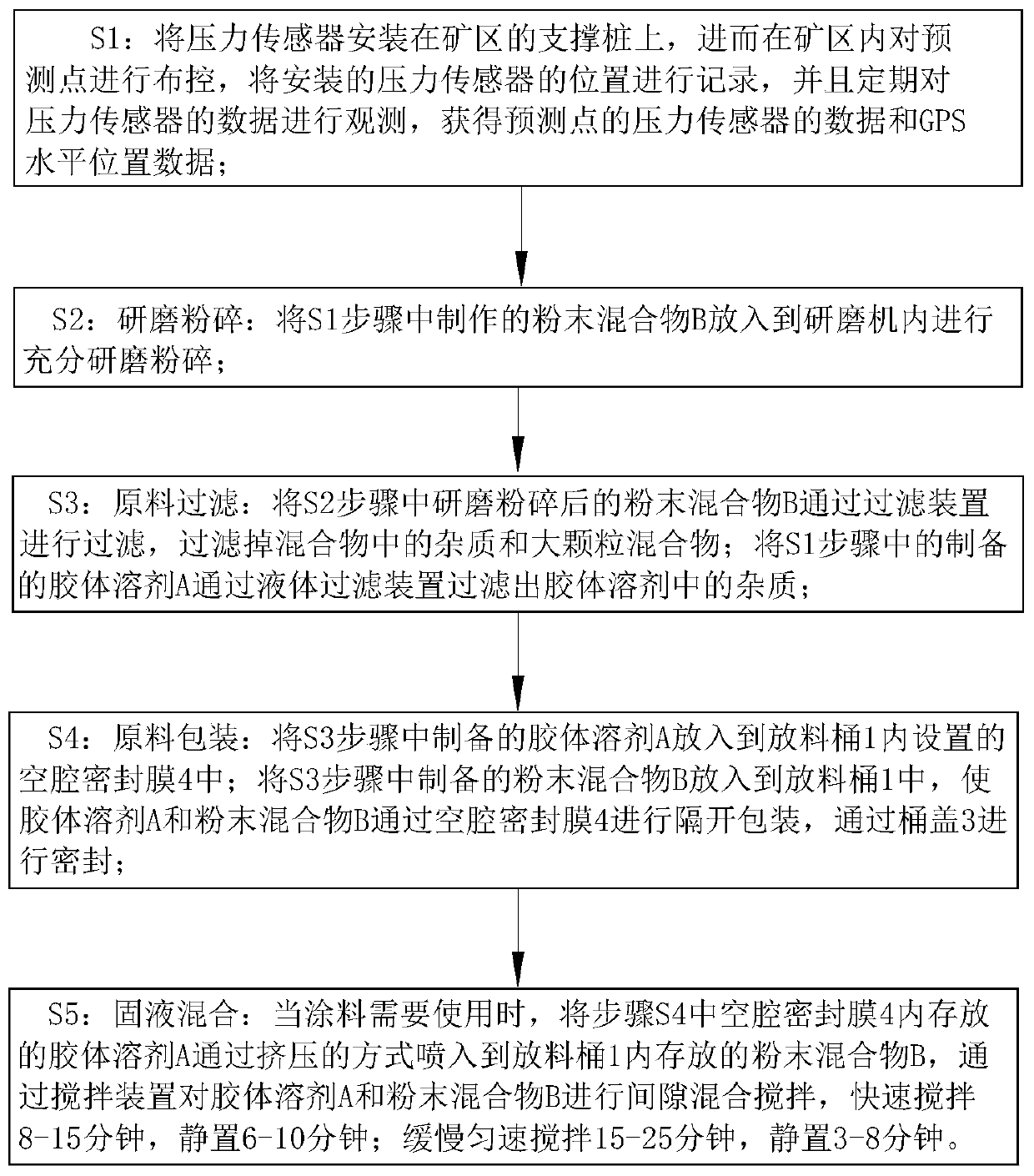

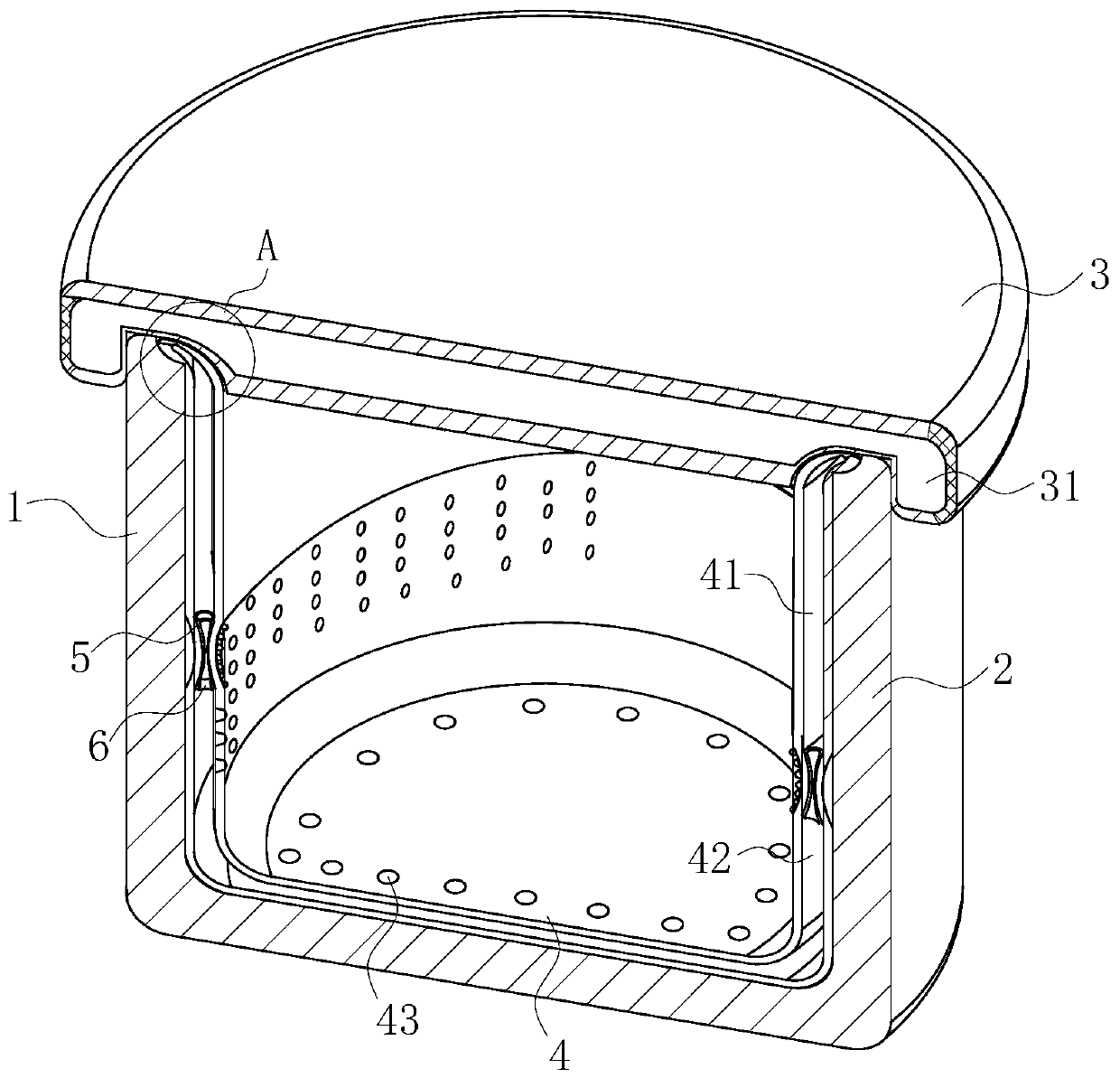

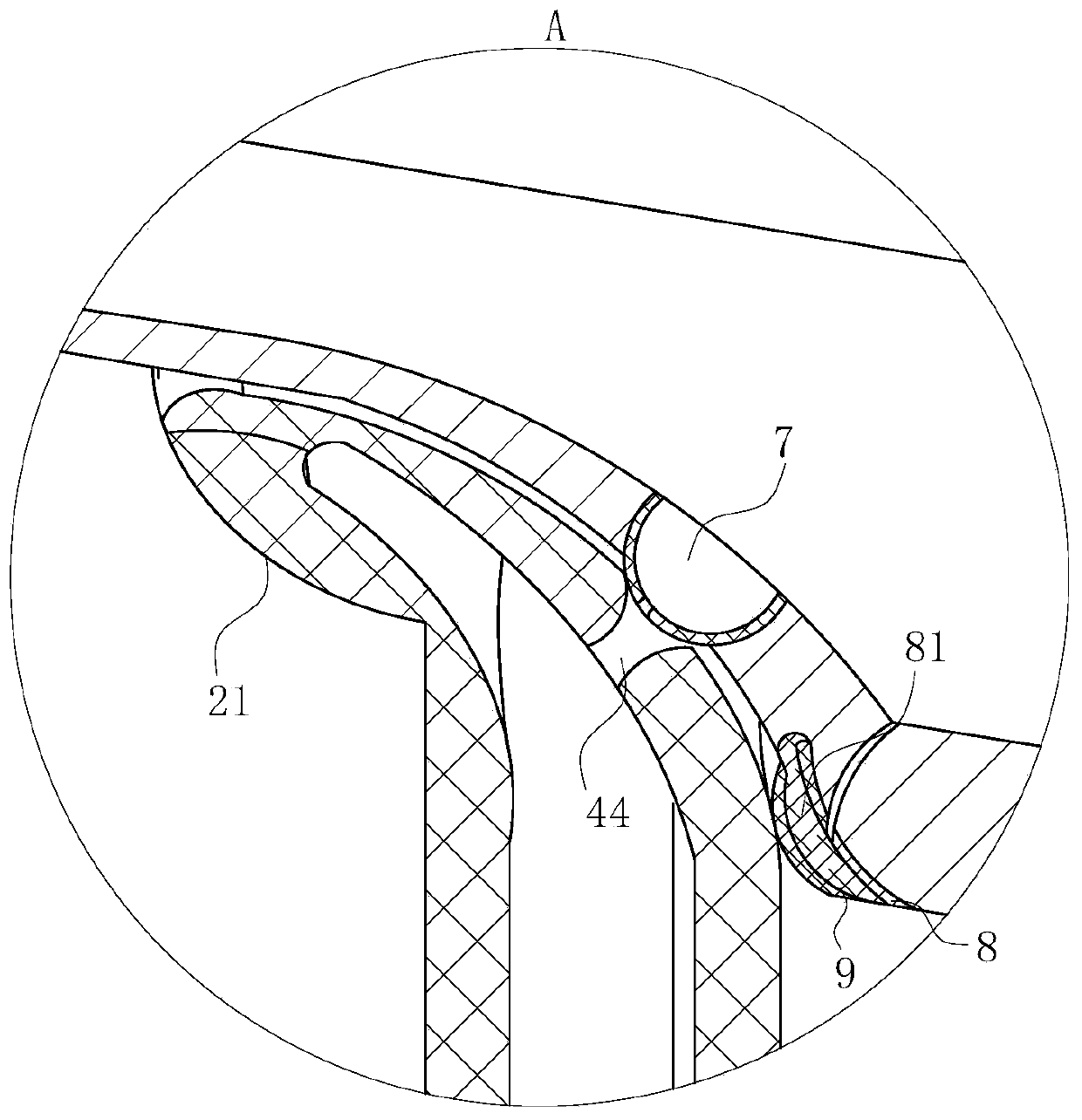

[0030] As an embodiment of the present invention, it also includes steps S5 and S5: solid-liquid mixing: when the paint needs to be used, spray the colloid solvent A stored in the cavity sealing film 4 in step S4 into the place by extrusion. For the powder mixture B stored in the material barrel 1, the colloidal solvent A and the powder mixture B are mixed and stirred by the stirring device, stirred rapidly for 8-15 minutes, and left to stand for 6-10 minutes; slowly stirred at a uniform speed for 15-25 minutes, left to stand 3-8 minutes; during work, when the paint needs to be used, turn the bung 3, so that the colloidal solvent A filled in the cavity sealing film 4 is extruded and sprayed into the powder mixture B placed in the barrel body 2, so that the colloidal solvent A A is mixed with powder mixture B, and the paint mixed in the paint bucket is stirred by a paint mixer, first stirring rapidly for 8-15 minutes, to prevent the initially mixed colloidal solvent A and powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com