Multi-needle electrostatic spinning device in constant-pressure liquid supply

An electrospinning and multi-needle technology, which is applied in the direction of feeding solution to spinnerets, textiles and papermaking, filament/thread forming, etc., can solve problems such as mutual interference of electrostatic fields, clogging of spinning needles, unstable jet flow, etc. , to achieve the effect of ensuring the diameter of the spinning fiber, avoiding the clogging of the needle, and ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments:

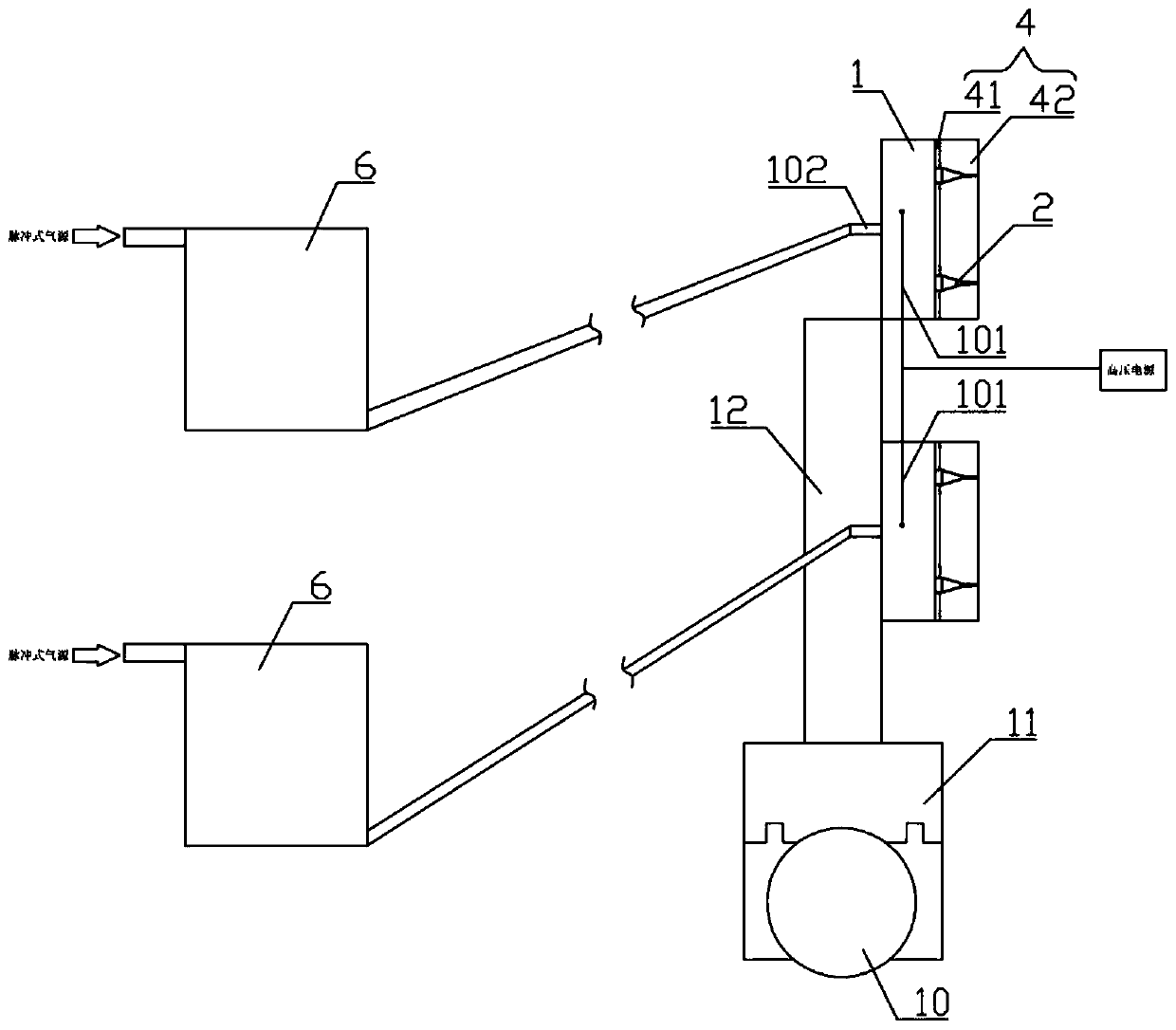

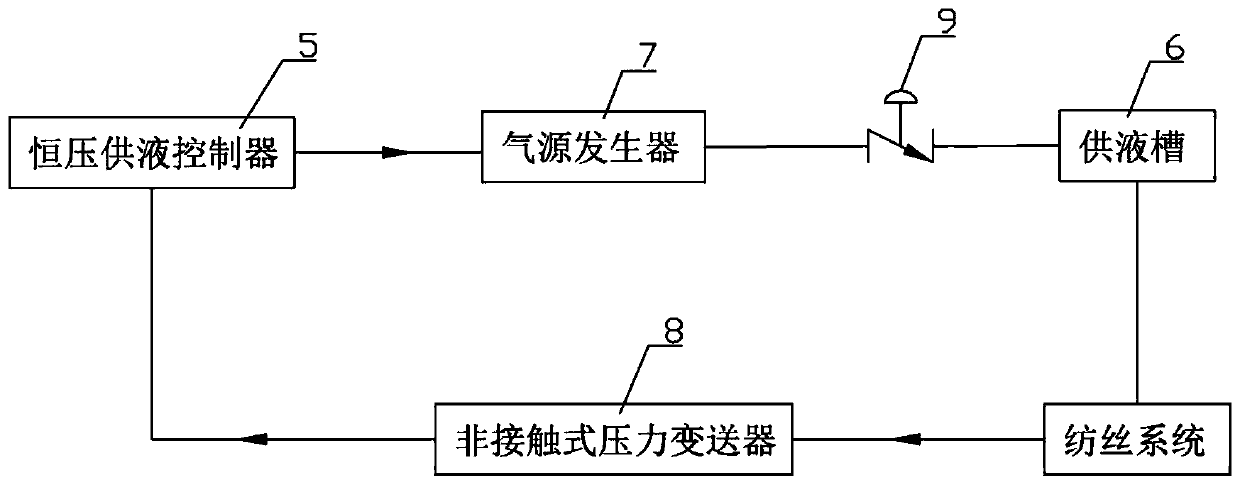

[0031] like Figure 1-Figure 5 As shown, a constant pressure liquid supply multi-needle electrospinning device of the present invention includes a reciprocating transmission system, a spinning system installed on the reciprocating transmission system, and a constant pressure liquid supply control system communicated with the spinning system.

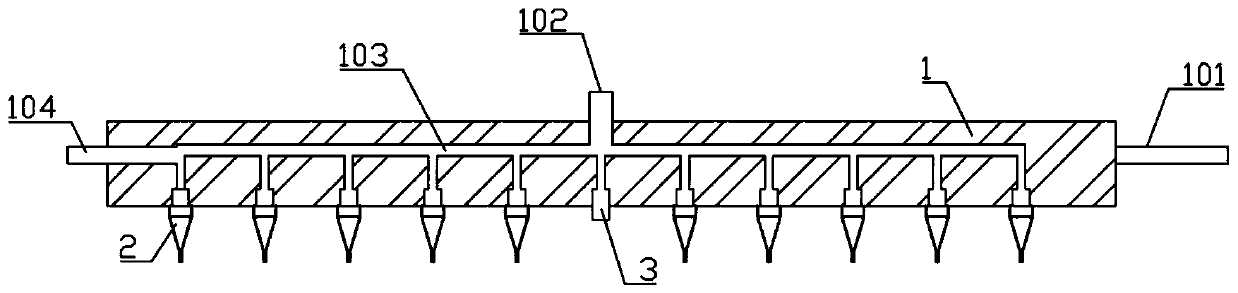

[0032] The spinning system includes at least one electrode 1. In this embodiment, two electrodes 1 are selected for illustration. One end of the electrode 1 is provided with a high-voltage power supply terminal 101. When in use, a high-voltage power supply terminal 101 is connected to the high-voltage power supply terminal. Power supply to create an electrostatic field. A plurality of needles 2 are fixedly installed on the electrode 1. The needles 2 of the present invention are Musashi-type needles. The needles of the Musashi-type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com