Pressure vessel with pollution discharge buffer device

A technology of pressure vessel and buffer device, which is applied in the field of pressure vessel to prevent pollution and ensure personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

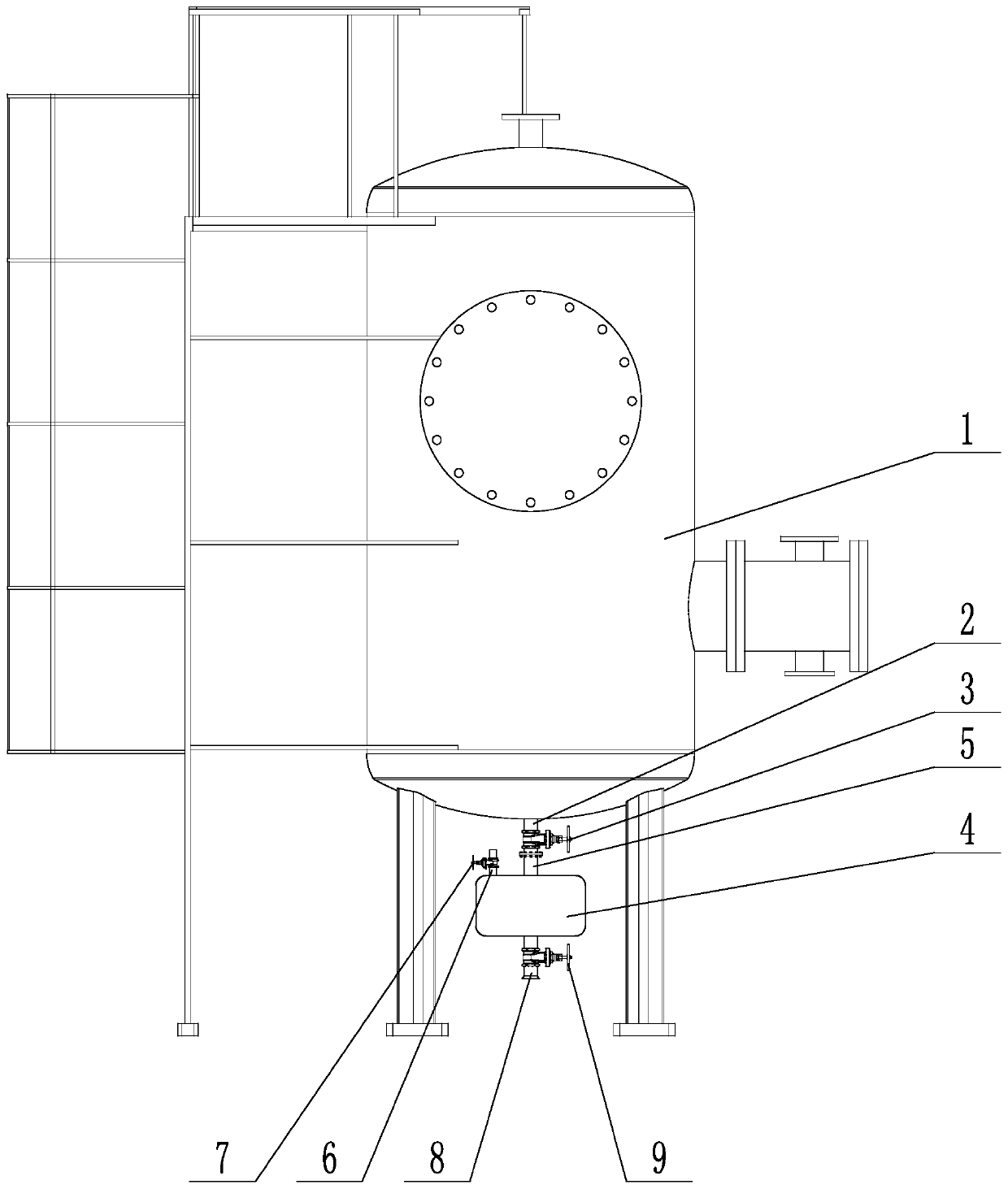

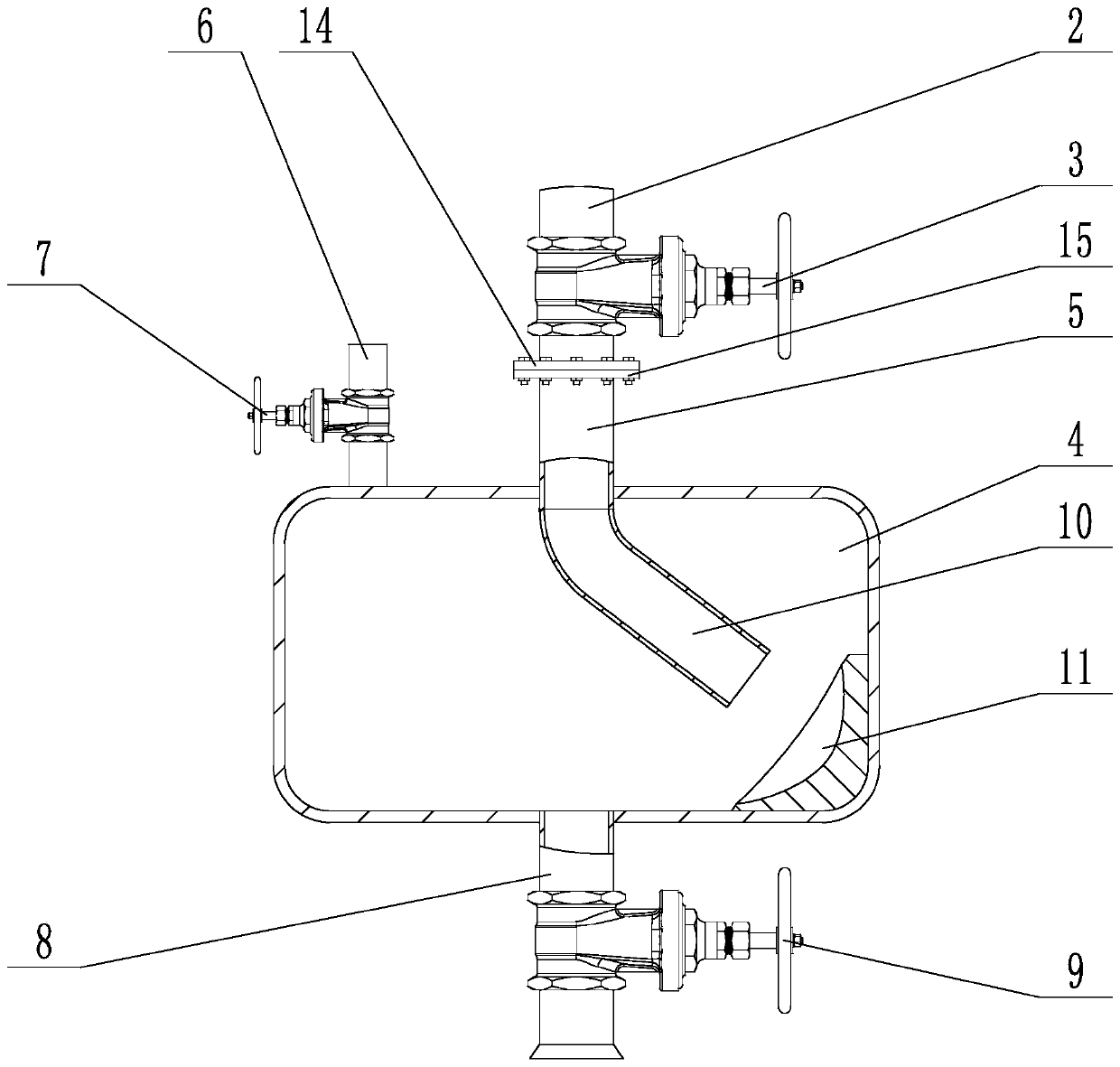

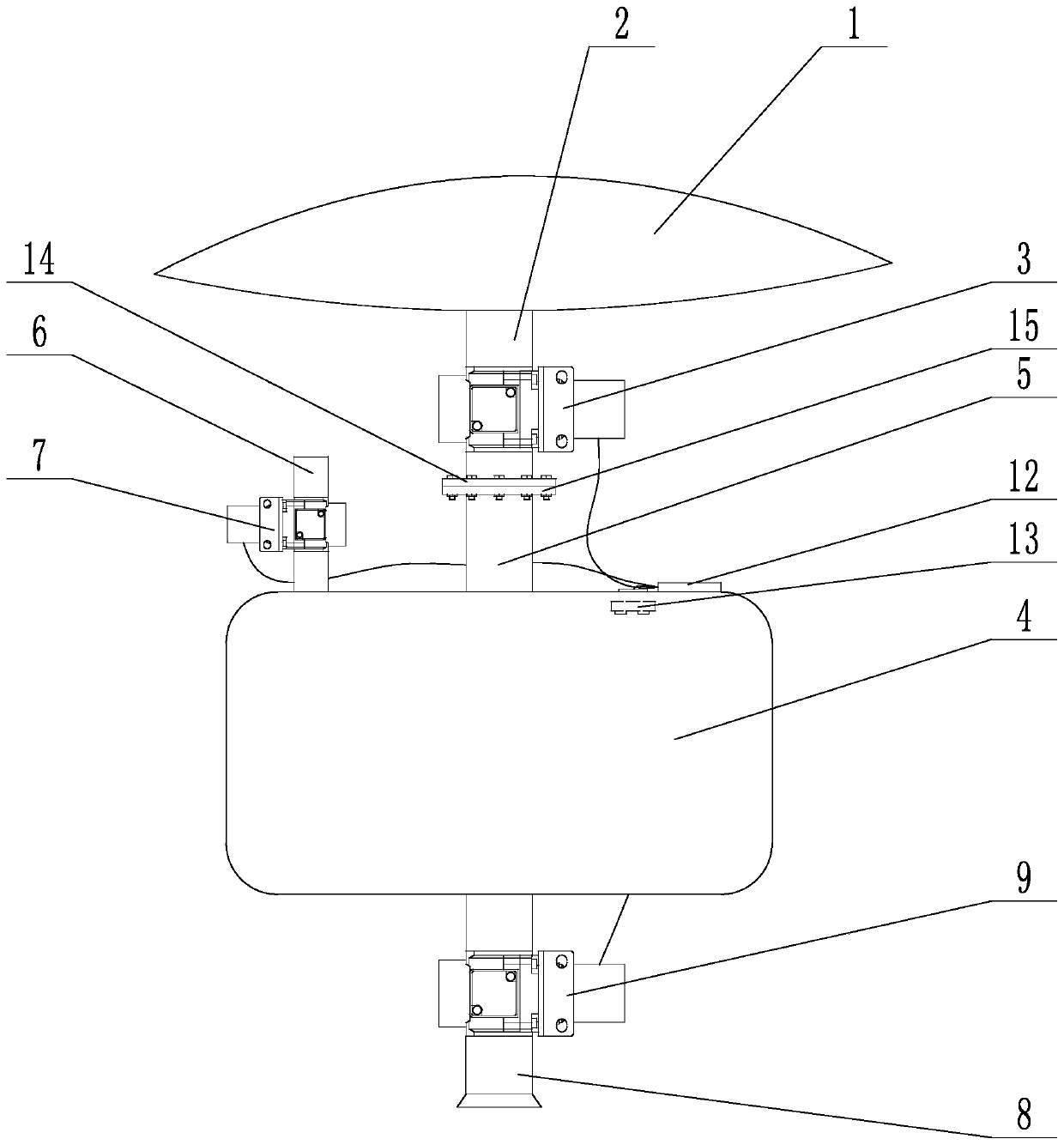

[0038] as attached figure 1 As shown, this embodiment takes a vertical gas pressure vessel as an example, a pressure vessel with a sewage buffer device, including a vessel body 1, and the pressure vessel is fixed on the ground through a frame body. A slag discharge pipe 2 is welded at the bottom of the container body 1 , and the slag discharge pipe communicates with the container body 1 . The slag discharge pipe 2 is connected in series with a first valve 3, and the bottom of the slag discharge pipe 2 is detachably and fixedly connected to a buffer tank 4, and the buffer tank can withstand the internal pressure of the pressure vessel. A centrally welded receiving pipe 5 on the top of the buffer tank 4 is used to connect with the slag discharge pipe 2. In this embodiment, the container body 1 and the buffer tank 4 are connected by sealing flanges. The bottom of the slag discharge pipe 2 is welded with a first flange 14, and the top of the receiving pipe 5 is welded with a seco...

Embodiment 1

[0041] For Embodiment 1, the first valve 3, the pressure relief valve 7, and the second valve 9 described in this embodiment are all solenoid valves, and the device further includes a controller, which is a single-chip microcomputer, which is connected to the single-chip microcomputer. Action control switch. The action control switch is used as a start signal for the single-chip microcomputer to control the cyclic actions of a plurality of solenoid valves. The single-chip microcomputer and the solenoid valve are powered by a DC power supply, and the first valve 3 , the pressure relief valve 7 , and the second valve 9 are all connected to the controller 12 by signal. In this embodiment, in order to ensure the stability of the pressure vessel, a manual valve can be connected in series above the first valve, so as to reduce the pressure impact on the first valve. In the device, the first valve, the second valve and the pressure relief valve are controlled by the single-chip micr...

Embodiment 2

[0044] For Embodiment 2, in this embodiment, the buffer tank 4 is provided with a sensor 13 , and the sensor 13 is signally connected to the controller 12 . The sensor 13 is a pressure sensor and / or a liquid level sensor. The pressure sensor is arranged on the inner top wall of the buffer tank, and the liquid level sensor adopts a photoelectric liquid level sensor. In order to facilitate the installation of the sensor, a wire hole is provided on the top of the buffer tank, and after the wire hole passes through the signal wire, it is sealed with a high-pressure sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com