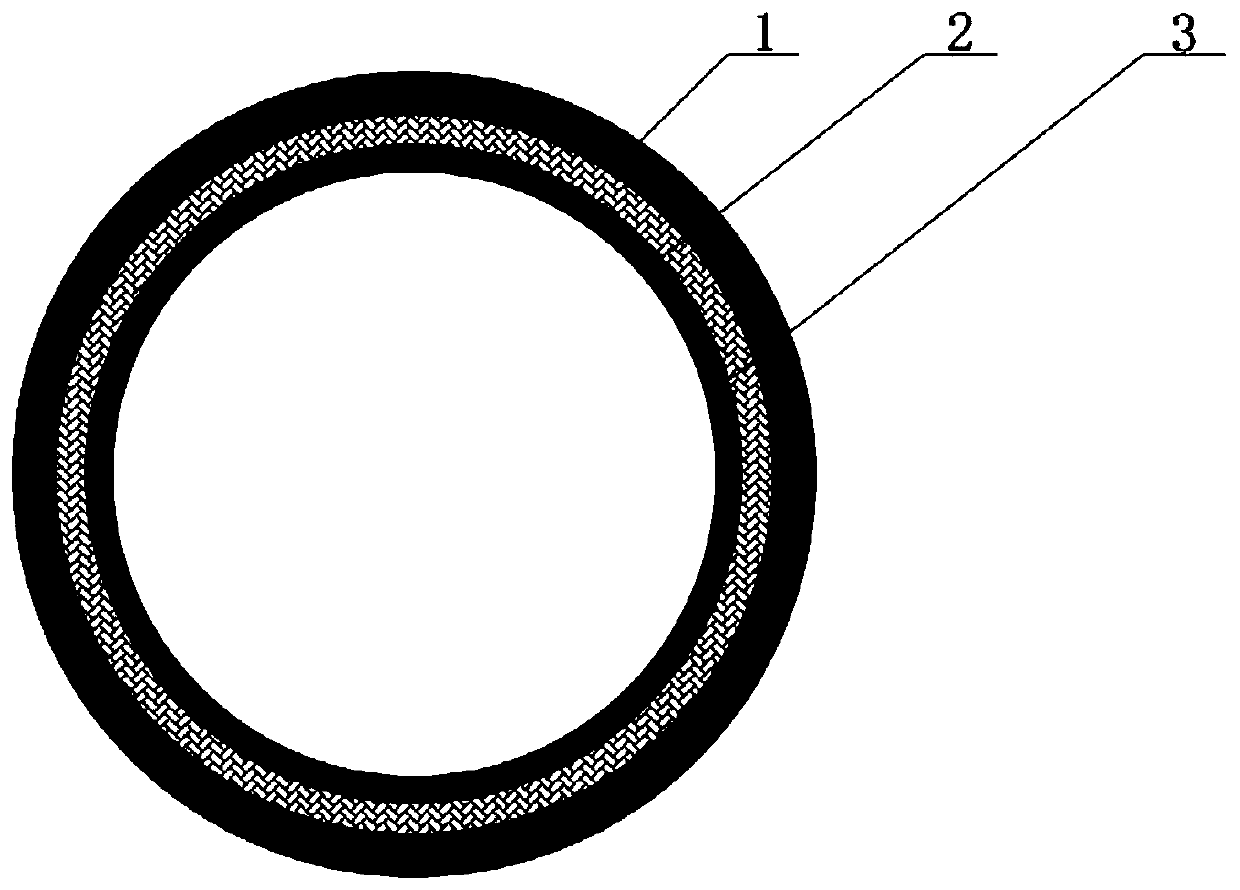

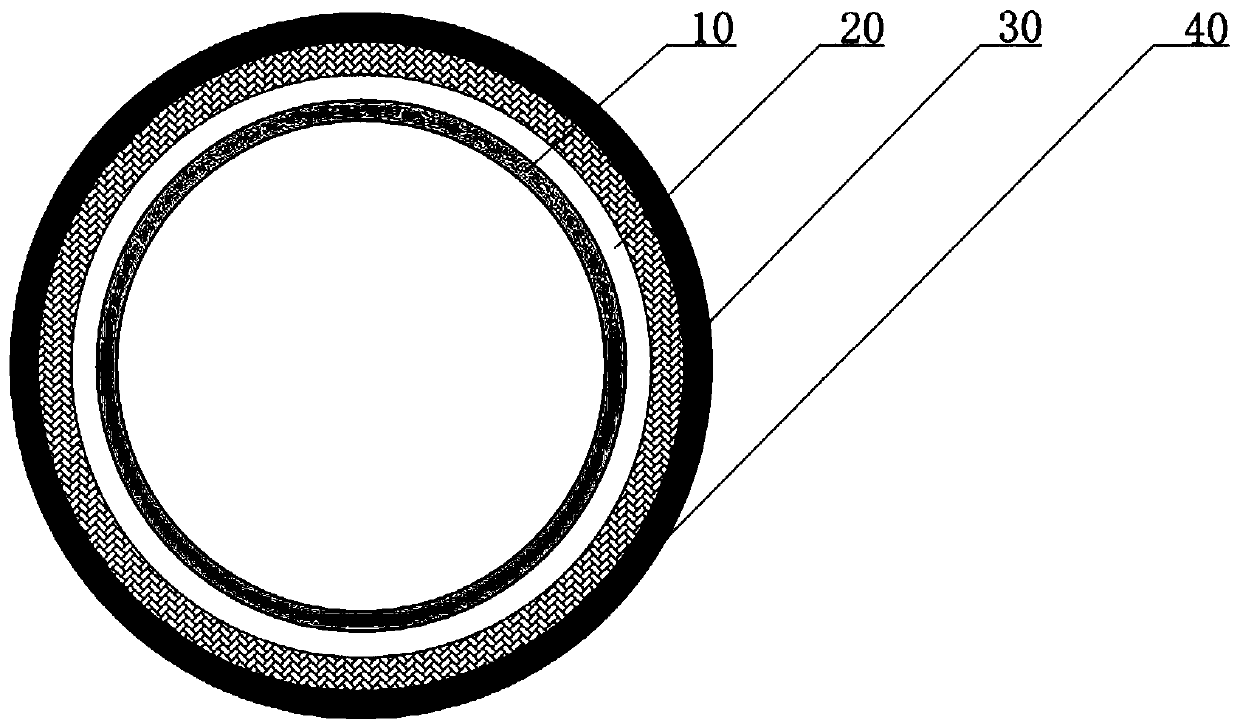

Wear-resisting high-pressure-resisting nonmetal composite flexible pipe used for mining and preparing method and application of wear-resisting high-pressure nonmetal composite flexible pipe

A composite flexible, non-metallic technology, used in applications, hoses, pipes, etc., can solve the problem of further improvement of comprehensive performance, and achieve the effect of small specific gravity, convenient transportation and storage, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

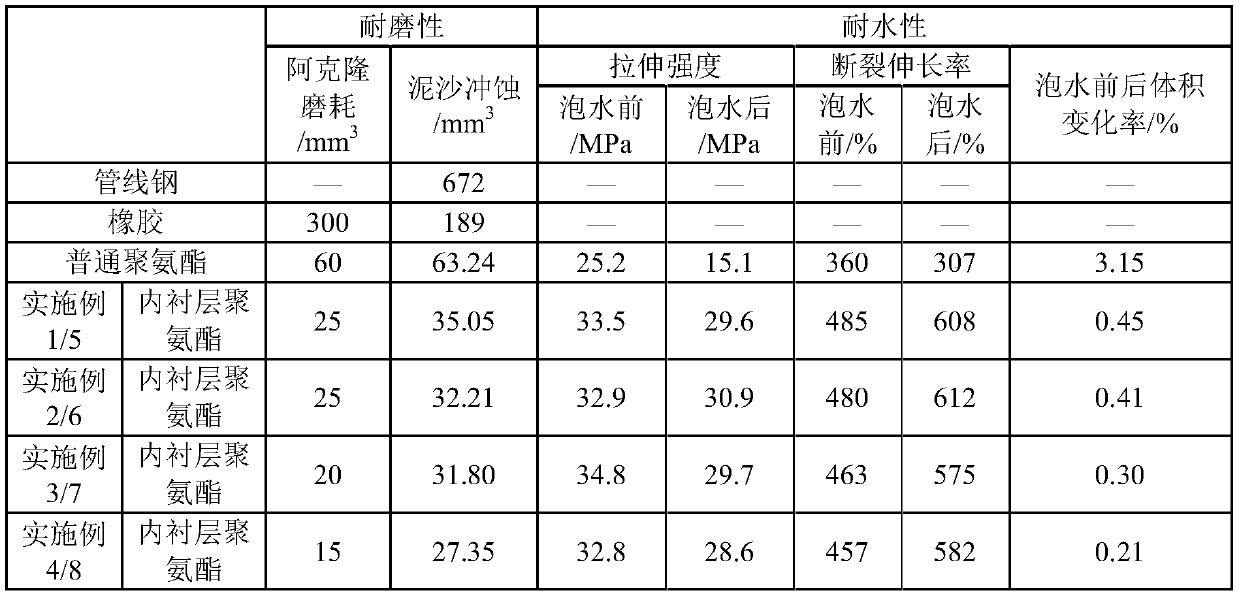

Embodiment 1

[0050] In the wear-resistant and high-pressure resistant non-metallic multi-layer composite flexible pipe of this embodiment, the formula of wear-resistant thermoplastic polyurethane is recorded as: 100 parts of thermoplastic polyurethane elastomer, 5 parts of wear-resistant filler carbon nanotubes, antioxidant 0.2 parts. The thermoplastic polyurethane elastomer used in this example is purchased from Wanhua, brand 8190. The basic performance requirements of the thermoplastic polyurethane elastomer used: hardness: 85-95, tensile strength ≥ 25MPa, tear strength ≥ 70N / mm.

[0051] The fibers used in the fiber reinforced layer in this embodiment are glass fibers with a fiber diameter of 1 mm.

[0052] In this embodiment, the outer protective layer is made of high-density polyethylene (HDPE), the tensile strength is ≥20 MPa, and the elongation at break is ≥400%.

[0053] In this embodiment, the pipe size of the thermoplastic polyurethane lining layer is: inner diameter 193.7mm, w...

Embodiment 2

[0062] In the wear-resistant and high-pressure resistant non-metal multi-layer composite flexible pipe of this embodiment, the formula of wear-resistant thermoplastic polyurethane is recorded as: 100 parts of thermoplastic polyurethane elastomer, 5 parts of wear-resistant filler molybdenum disulfide, antioxidant 0.3 parts; the thermoplastic polyurethane elastomer used in this example is produced by purchased Wanhua, brand 8290. The basic performance requirements of the thermoplastic polyurethane elastomer used: hardness: 85-95, tensile strength ≥ 25MPa, tear strength ≥ 70N / mm.

[0063] The fibers used in the fiber reinforced layer in this embodiment are aramid fibers with a diameter of 1 mm, a twist of 41, and a Z direction.

[0064] In this embodiment, the outer protective layer is made of high-density polyethylene (HDPE), the tensile strength is ≥20 MPa, and the elongation at break is ≥400%.

[0065] In this embodiment, the pipe size of the thermoplastic polyurethane lining...

Embodiment 3

[0068] In the wear-resistant and high-pressure resistant non-metallic multilayer composite flexible pipe of this embodiment, the formula of wear-resistant thermoplastic polyurethane is recorded as: 100 parts of thermoplastic polyurethane elastomer, 2 parts of wear-resistant filler graphene, 3 parts of carbon nanotubes part, 0.3 part of antioxidant; the thermoplastic polyurethane elastomer used in this example is produced by purchased Wanhua, the brand mainly has 8190. The basic performance requirements of the thermoplastic polyurethane elastomer used: hardness: 85-95, tensile strength ≥ 25MPa, tear strength ≥ 70N / mm.

[0069] The fibers used in the fiber reinforced layer in this embodiment are aramid fibers with a fiber diameter of 2 mm, a twist of 70, and a Z direction.

[0070] In this embodiment, the outer protective layer is made of TPU8190 pure material, the tensile strength is ≥25 MPa, and the elongation at break is ≥400%.

[0071] In this embodiment, the pipe size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com