Pebble-bed high-temperature gas cooled reactor high neutron multiplication performance fuel element

A high-temperature gas-cooled reactor and fuel element technology, applied in the field of nuclear reactors, can solve the problems of expensive fuel core materials and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

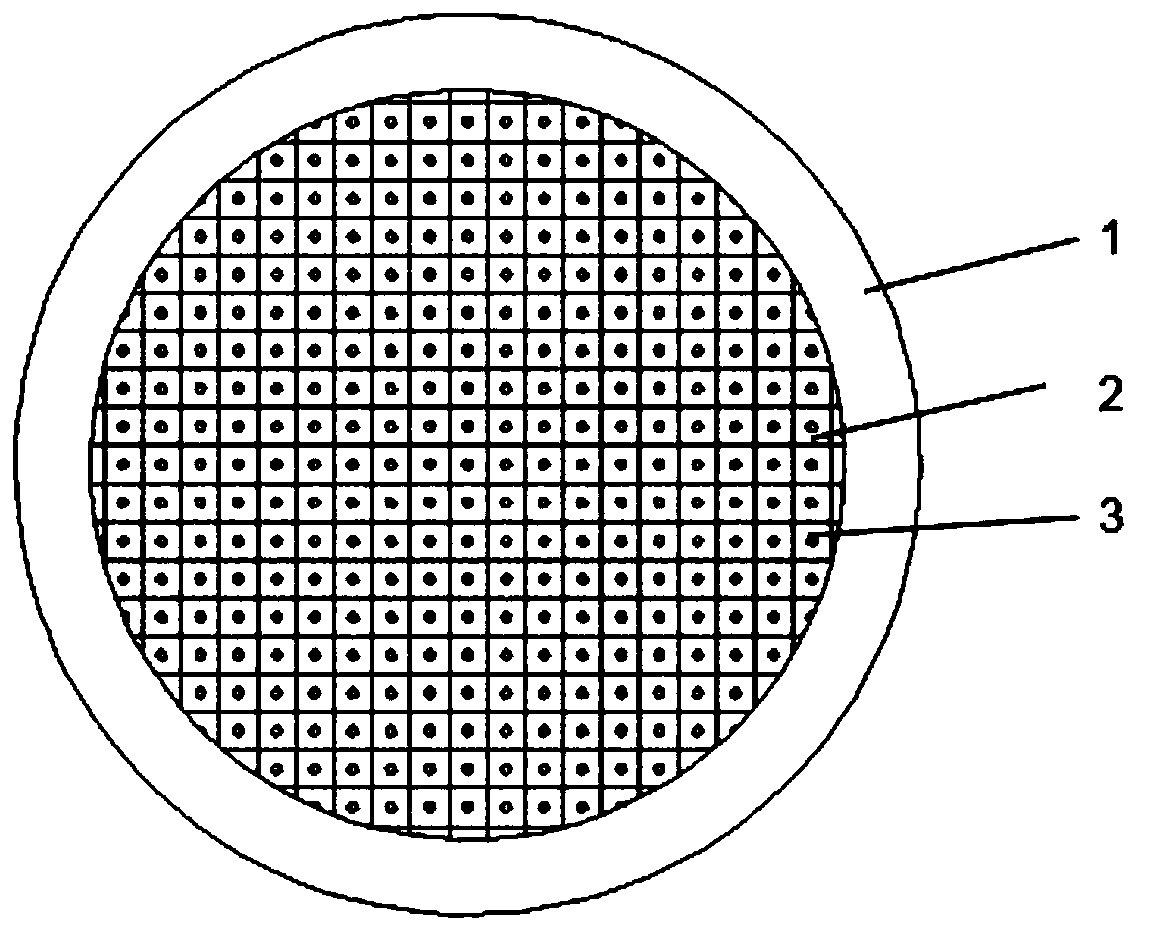

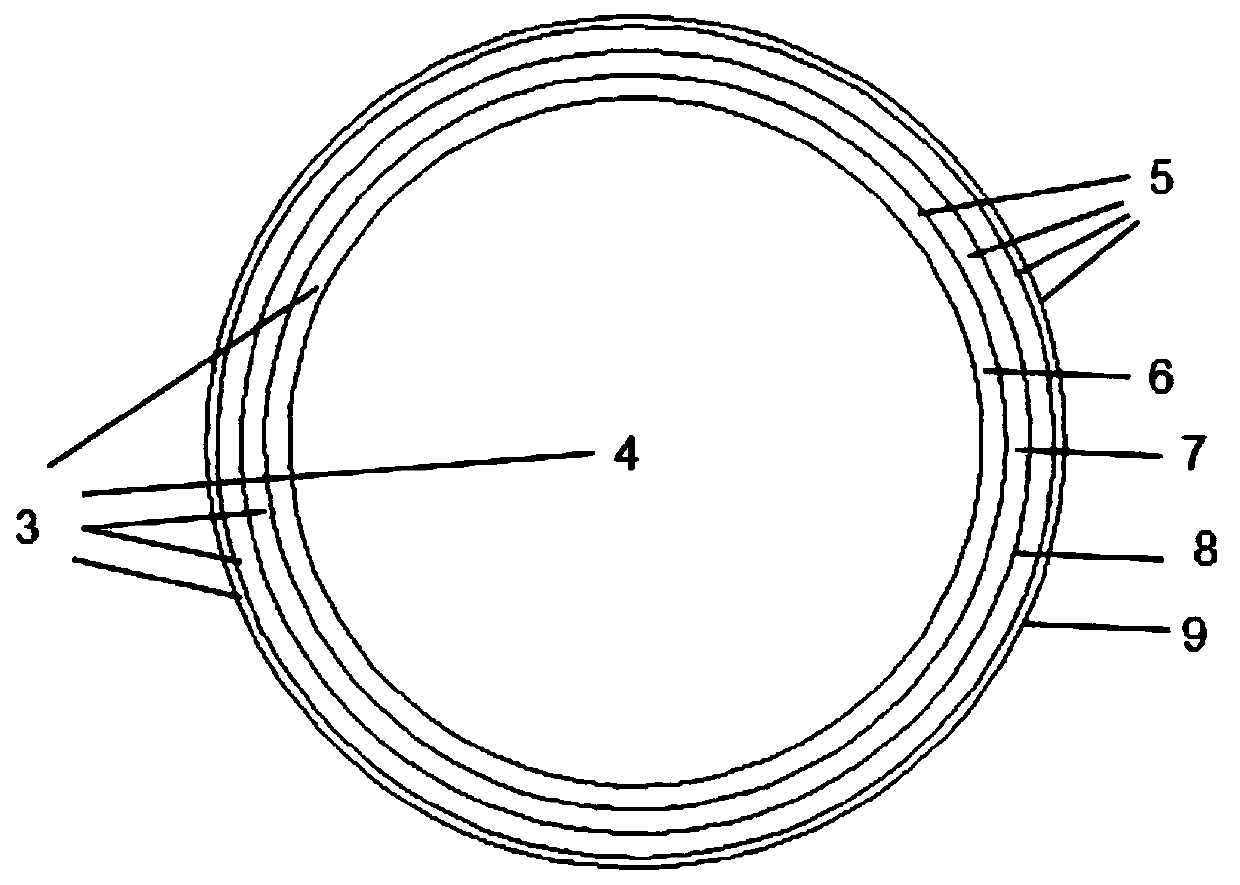

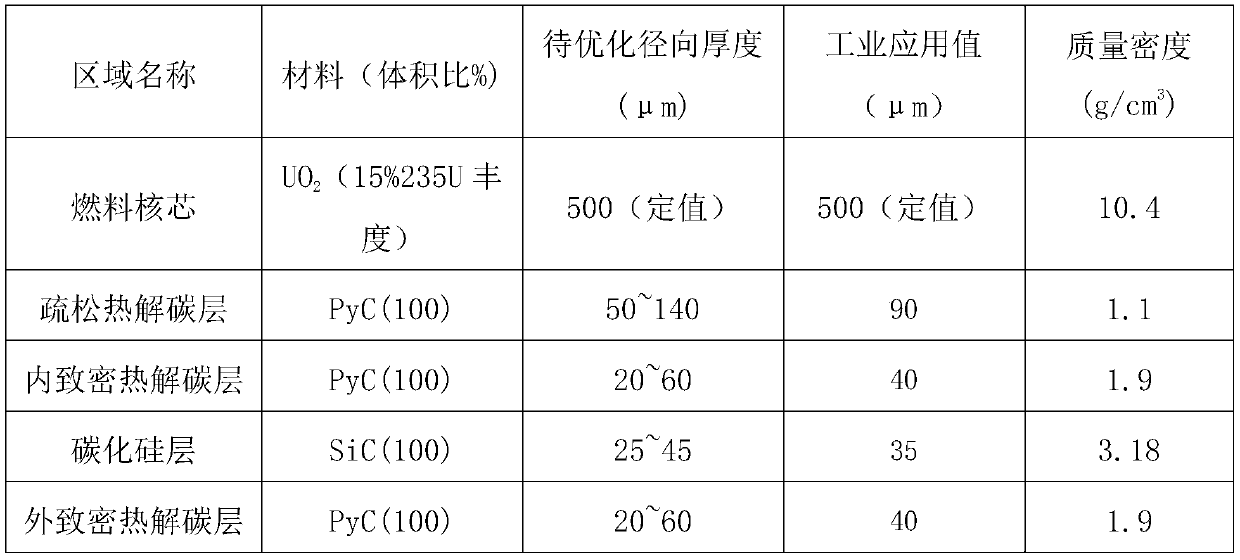

[0027] Figure 1 to Figure 2 An embodiment of a high neutron multiplying performance fuel element for a pebble bed type high temperature gas-cooled reactor of the present invention is given. The fuel element includes a graphite cladding 1 and a graphite matrix 2 from the outside to the inside. A plurality of coated fuel particles 3 are uniformly distributed on the spherical coordinates, and the coated fuel particles 3 include uranium dioxide core particles 4 and a coating layer 5 from the inside to the outside along the radial direction. It is followed by a loose pyrolytic carbon layer 6, an inner dense pyrolytic carbon layer 7, a silicon carbide layer 8, and an outer dense pyrolytic carbon layer 9. The thickness of each layer of the coating layer 5 is within the diameter and richness of the uranium dioxide core 4 It is obtained after multi-objective optimization under the condition of fixed concentration. Since the thickness of each layer of the coating layer is usually design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com